| Price | EXW/FOB/CIF/DDP |

| MOQ | 100PCS |

| Delivery Time | 20-30days |

| Brand | FODOR |

| Place of Origin | China |

| Certification | ISO9001:2015 |

| Model Number | HEAT SINK-S0020 |

| Packaging Details | Blister packaging |

| Payment Terms | T/T, Western Union |

| Supply Ability | 30000 PCS Per month |

| Place of Origin | China | Delivery time | 20-30days |

| Keyword | skived fin heat sink | Packaging Details | Blister packaging |

| Model Number | HEAT SINK-S0020 | Supply Ability | 30000 PCS Per month |

| Processing Service | CNC,plating nicle | Certification | ISO9001:2015 |

| Brand Name | FODOR | Payment Terms | T/T, Western Union |

| Raw Material | Pure Copper | Price | EXW/FOB/CIF/DDP |

| Delivery Time | 20-30days | Minimum Order Quantity | 100PCS |

| Surface Treatment | clean | Application | Copper Skived fin heat sink |

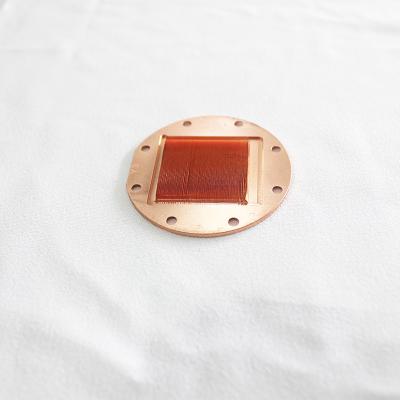

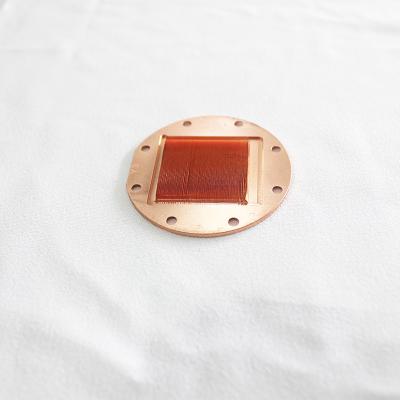

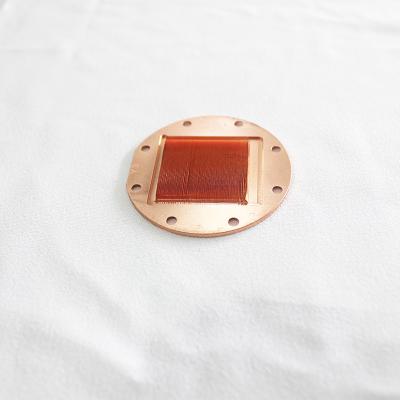

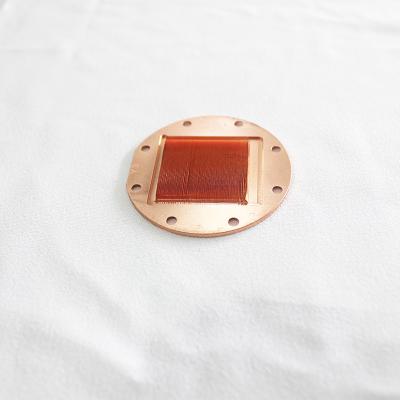

Pure Copper Skived Fin Heat Sink For Electronics Equipment With ISO9001

Quick Detail

| Raw Material | Pure Copper |

| Custom Service | Yes, OEM/ODM Service |

| Quality System | ISO9001:2015 |

| Processing Technology | CNC Gear /Wood machining/CNC/Riveting |

| Surface treatment | clean |

| Packing Way | Blister packaging or special packing you would like |

| Application Scenario | Electronic equipment heat sink |

| MOQ Request | 100/500/1000 |

Description

This heat sink is based aluminum profile 6063-T5 material to processing, first of all, we check the raw material dimension is fine or not, the second is that according to the drawing, use the CNC Gear shovel machine to do the dimension, the third is that accroding to the drawing, the forth is that use the CNC to do exact dimension, the fifth is do anodizing clear, the last step is riveting, and then inspection/packing. First inspection and patrol inspection are done in processing .

Notes

This is a skived fin heat sink

SKIVING

HEAT

SINK

This

design,

which

is

much

more

precise,

has

outstanding

thermal

solution

and

is

utlized

to

produce

intensive

fin

spread.

Skiving

heat

sink

also

require

minmal

tooling

charges,

which

is

a

better

choice

for

you

if

cost-down

has

been

considered.

FEATURES

It’s

implemented

with

cutting

tool

to

slice

the

metal

material

into

thin

pieces.

Its

integrated

structure

and

thin

fin

could

maximize

the

thermal

dissipation

area.

Both

Aluminum

and

copper

are

acceptable.

However,

the

height

of

heat

sink

in

this

process

and

the

shape

are

limited.

Fodor can offer copper skived fi heat sink and aluminum(AL1050/6063) skived fin heat sink.