| Price | EXW/FOB/CIF/DDP |

| MOQ | 100PCS |

| Delivery Time | 20-30days |

| Brand | FODOR |

| Place of Origin | China |

| Certification | ISO9001:2015 |

| Model Number | HEAT SINK-S0014 |

| Packaging Details | Blister packaging |

| Payment Terms | T/T, Western Union |

| Supply Ability | 30000 PCS Per month |

| Place of Origin | China | Delivery time | 20-30days |

| Keyword | skived fin heat sink | Packaging Details | Blister packaging |

| Model Number | HEAT SINK-S0014 | Supply Ability | 30000 PCS Per month |

| Processing Service | CNC,plating nicle | Certification | ISO9001:2015 |

| Brand Name | FODOR | Payment Terms | T/T, Western Union |

| Raw Material | AL1050 | Price | EXW/FOB/CIF/DDP |

| Delivery Time | 20-30days | Minimum Order Quantity | 100PCS |

| Surface Treatment | detail request | Application | Aluminum Skived fin heat sink |

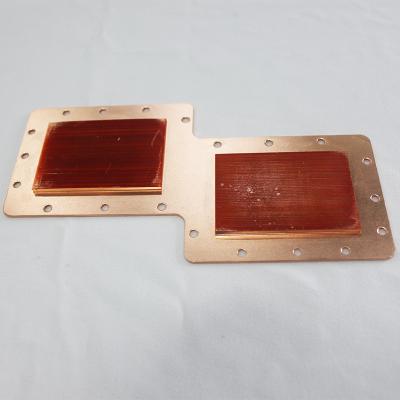

Free Mold Aluminum 1050 Mini Skived Fin Heat Sink With Quick Samples

Quick Detail

| Raw Material | AL1050 |

| Custom Service | Yes, OEM/ODM Service |

| Quality System | ISO9001:2015 |

| Processing Technology | CNC Gear /Wood machining/CNC/Riveting |

| Surface treatment | clean |

| Packing Way | Blister packaging or special packing you would like |

| Application Scenario | Electronic equipment heat sink |

| MOQ Request | 100/500/1000 |

Description

This heat sink is based aluminum profile 6063-T5 material to processing, first of all, we check the raw material dimension is fine or not, the second is that according to the drawing, use the CNC Gear shovel machine to do the dimension, the third is that accroding to the drawing, the forth is that use the CNC to do exact dimension, the fifth is do anodizing clear, the last step is riveting, and then inspection/packing. First inspection and patrol inspection are done in processing.

Notes

This is a skived fin heat sink

A Skived Heatsink offers excellent thermal properties compared with other manufacturing methods as it offers a thin finned heatsink, with a dense population of uniformly shaped and distributed fins. As a Skived Heatsink is made from a single block of material such as copper or aluminum additional interface resistance that is common in other heatsink manufacturing processes such as stamped or folded fins that have a thermal resistance from the use of solder to attached the fins. This combination of high aspect ratio thin fins with no thermal resistance interface produces optimum cooling performance in high airflow applications.

Fodor can offer copper skived fi heat sink and aluminum(AL1050/6063) skived fin heat sink.