| Price | EXW/FOB/CIF/DDP |

| MOQ | 100PCS |

| Delivery Time | 20-30days |

| Brand | FODOR |

| Place of Origin | China |

| Certification | ISO9001:2015 |

| Model Number | HEAT SINK-S0016 |

| Packaging Details | Blister packaging |

| Payment Terms | T/T, Western Union |

| Supply Ability | 30000 PCS Per month |

| Place of Origin | China | Delivery time | 20-30days |

| Keyword | skived fin heat sink | Packaging Details | Blister packaging |

| Model Number | HEAT SINK-S0016 | Supply Ability | 30000 PCS Per month |

| Processing Service | CNC, plating nicle | Certification | ISO9001:2015 |

| Brand Name | FODOR | Payment Terms | T/T, Western Union |

| Raw Material | AL1050/6063 | Price | EXW/FOB/CIF/DDP |

| Delivery Time | 20-30days | Minimum Order Quantity | 100PCS |

| Surface Treatment | clean or custom | Application | Aluminum Skived fin heat sink |

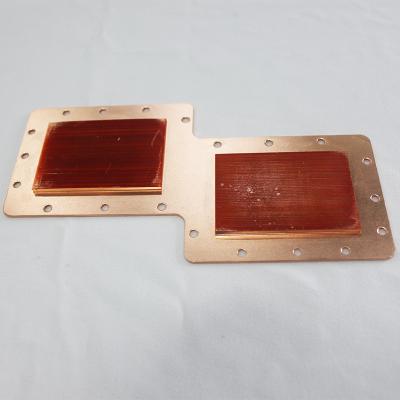

Quick Sample Aluminum 6063 Skived Fin Heat Sink With Rosh For Led Light

Quick Detail

| Raw Material | AL1050 |

| Custom Service | Yes, OEM/ODM Service |

| Quality System | ISO9001:2015 |

| Processing Technology | CNC Gear /Wood machining/CNC/Riveting |

| Surface treatment | clear anodizing |

| Packing Way | Blister packaging or special packing you would like |

| Application Scenario | Electronic equipment heat sink |

| MOQ Request | 100/500/1000 |

Description

This heat sink is based aluminum profile 6063-T5 material to processing, first of all, we check the raw material dimension is fine or not, the second is that according to the drawing, use the CNC Gear shovel machine to do the dimension, the third is that accroding to the drawing, the forth is that use the CNC to do exact dimension, the fifth is do anodizing clear, the last step is riveting, and then inspection/packing. First inspection and patrol inspection are done in processing.

Notes

This is a skived fin heat sink

How

to

identify

a

Skived

Heatsink

Skived

HeatsinkIt

is

fairly

easy

to

identify

Skived

Heatsink

as

the

heatsink

has

a

curve

where

the

blade

finishes

its

cut

at

the

base

of

the

heatsink

as

shown

in

the

picture.

In

addition,

the

fins

are

not

completely

vertical,

and

curve

slightly.

This

is

more

pronounced

at

the

fins

get

taller.

Typical

width

of

the

plate

fin

is

200

mm,

but

it

is

possible

to

manufacture

up

to

400

mm

wide

heatsinks

by

rotating

the

block

of

material

and

running

a

second

pass

with

the

curvature

of

the

fins

being

in

the

opposite

direction.

As

a

Skived

heatsink

is

manufactured

from

a

long

block

of

material,

the

only

is

no

real

limit

to

length

of

the

heatsink

is

the

length

of

the

block.

Different

heights

can

be

achieved

by

machining

the

block

of

material.

Any

excess

material

is

recycled

to

reduce

wastage.

Typical

Finishes

for

Aluminum

skived

heatsink

are

Anodization,

or

Nickel

Plated.

Typical

finished

for

Copper

Skived

heatsinks

are

Anti-Oxidant,

or

Nickel

Plated.

Fodor can offer copper skived fi heat sink and aluminum(AL1050/6063) skived fin heat sink.