| Price | EXW/FOB/CIF/DDP |

| MOQ | 100PCS |

| Delivery Time | 20-30days |

| Brand | FODOR |

| Place of Origin | China |

| Certification | ISO9001:2015 |

| Model Number | HEAT SINK-S0017 |

| Packaging Details | Blister packaging |

| Payment Terms | T/T, Western Union |

| Supply Ability | 30000 PCS Per month |

| Place of Origin | China | Delivery time | 20-30days |

| Keyword | skived fin heat sink | Packaging Details | Blister packaging |

| Model Number | HEAT SINK-S0017 | Supply Ability | 30000 PCS Per month |

| Processing Service | CNC,plating nicle | Certification | ISO9001:2015 |

| Brand Name | FODOR | Payment Terms | T/T, Western Union |

| Raw Material | AL6063 | Price | EXW/FOB/CIF/DDP |

| Delivery Time | 20-30days | Minimum Order Quantity | 100PCS |

| Surface Treatment | Anodizing black | Application | Aluminum Skived fin heat sink |

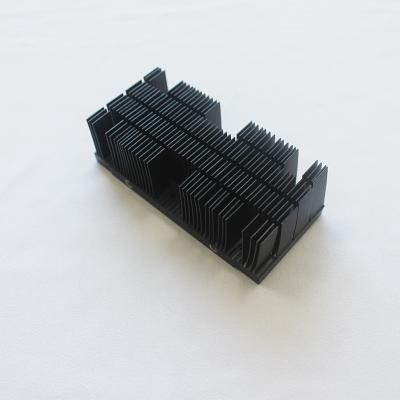

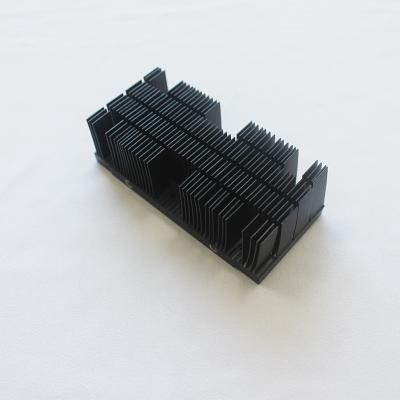

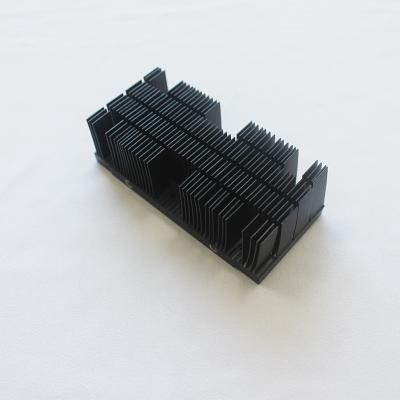

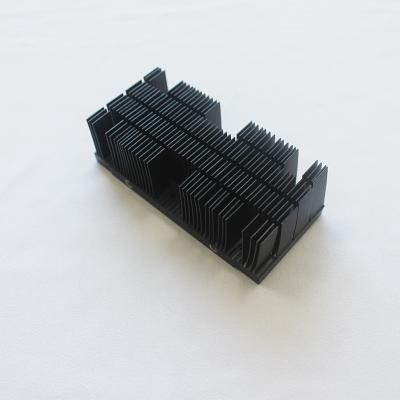

Quick Sample Aluminum 6063 Skived Fin Heat Sink With Rosh For Led Light

Quick Detail

| Raw Material | AL1050 |

| Custom Service | Yes, OEM/ODM Service |

| Quality System | ISO9001:2015 |

| Processing Technology | CNC Gear /Wood machining/CNC/Riveting |

| Surface treatment | black anodizing |

| Packing Way | Blister packaging or special packing you would like |

| Application Scenario | Electronic equipment heat sink |

| MOQ Request | 100/500/1000 |

Description

This heat sink is based aluminum profile 6063-T5 material to processing, first of all, we check the raw material dimension is fine or not, the second is that according to the drawing, use the CNC Gear shovel machine to do the dimension, the third is that accroding to the drawing, the forth is that use the CNC to do exact dimension, the fifth is do anodizing clear, the last step is riveting, and then inspection/packing. First inspection and patrol inspection are done in processing.

Notes

This is a skived fin heat sink

Skived Heatsink Examples

In this example a copper skived heatsink was manufactured to create two sets of fins with different heights. Some of the taller fins were removed, and additional machining operations were added requirements of the application to accommodate other components in the assembly. Originally the customer was using a CNC machine to make the copper heatsink. By making a few changes to the heatsink drawing, they were able to utilize a higher performing heatsink with lower manufacturing costs.

Fodor can offer copper skived fi heat sink and aluminum(AL1050/6063) skived fin heat sink.