| Price | Negotiated |

| MOQ | Negotiable |

| Delivery Time | 5 - 8 work days |

| Brand | Komastu |

| Place of Origin | Japan |

| Model Number | 6D102 - 7 |

| Packaging Details | Neutral Package or Fumigation Free |

| Payment Terms | D/P, T/T |

| Supply Ability | 10 pieces |

| Condition | Used | Engine model | PC200 - 7 |

| Place of Origin | Japan | Packaging Details | Neutral Package or Fumigation Free |

| Color | Same as pictures | Excavator model | PC200 - 7 |

| Material | Steel | Model Number | 6D102 - 7 |

| Supply Ability | 10 pieces | Brand Name | Komastu |

| Payment Terms | D/P, T/T | Type | Diesel Engine |

| Price | Negotiated | Delivery Time | 5 - 8 work days |

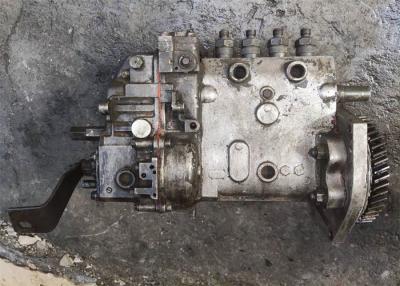

| Product name | Used Fuel Injection Pump | Part number | 101062 - 9310 |

6D102-7 Used Fuel Injection Pump For Excavator PC200 - 7 101062 - 9310 101609 - 3760

Specification

| Car name: Fuel Injection Pump | Model Number: 6D102 - 7 | |

| Quality: High quality | Engine type: Diesel | |

| Application: Excavator | Part code: 101609 - 3760 | |

| Cooling: Water cooling | Injection: Direct | |

Description

A Two-Headed Monster – A Pair of Reasons that Explain Fuel Injector Pump Failure

Problem

#1

–Low

Fuel

Tank

Level

If

your

main

goal

in

life

was

to

destroy

diesel

fuel

pump

injectors,

you’d

run

your

car

with

the

fuel

tank

as

close

to

empty

as

possible.

It

all

has

to

do

with

lubrication.

With

plenty

of

diesel

fuel

in

the

tank,

the

fuel

pump

bearings

receive

plenty

of

lubrication.

With

a

near-empty

tank,

the

fuel

system

is

suddenly

pushing

air

instead

of

diesel

fuel.

Anything

but

diesel

fuel

can

wear

out

the

fuel

pump

bearings,

which

means

the

fuel

injectors

will

not

receive

the

fuel

at

the

pressurized

level

(30,000

psi,

40,000

psi,

etc.)

it

should

be.

Problem

#2

–

Foreign

Object

Inside

Injector

Diesel

fuel

pump

injectors

are

high-precision

components.

They

also

deal

with

a

tremendous

amount

of

motion

and

other

stresses.

One

small

visitor

inside

(a

piece

of

dust,

debris,

etc.)

can

clog

the

injector.

Worse

yet,

a

microscopic

object

can

leave

the

injector

open

all

the

time.

If

the

injector

can’t

close,

cylinder

performance

is

compromised.

Problem

#3

–

Bad

Injector

Timing

Whenever

the

fuel

injector

pump’s

O-rings

or

ball

seats

are

defective,

the

timing

of

the

fuel

transfer

process

is

disrupted.

This

is

a

common

diesel

fuel

injector

pump

glitch,

and

usually

requires

a

complete

injection

pump

rebuild

or

replacement.

Maintenance

Reminder

Here’s

the

good

news

about

fuel

injector

pump

problems:

avoiding

disaster

is

simple.

In

fact,

if

you

do

these

three

things,

you’ll

enjoy

great

performance

and

minimal

repair

costs:

· Purchase clean, reliable fuel

· Change your fuel filter every 40,000 miles

· Keep your fuel tank at least one-quarter full most of the time

Injection pump – this part is a meter and pressurize fuel for injection. Governor – supply fuel in accordance to the load. Fuel injector – supplies fuel from the injection pump to the cylinders. Fuel filter – to filter dirt, duct and abrasive particles from blocking the injection system.