| Price | Negotiated |

| MOQ | Negotiable |

| Delivery Time | 5 - 8 work days |

| Brand | Komastu |

| Place of Origin | Japan |

| Model Number | 4D95 |

| Packaging Details | Neutral Package or Fumigation Free |

| Payment Terms | D/P, T/T |

| Supply Ability | 10 pieces |

| Condition | Used | Engine model | 4D95 |

| Place of Origin | Japan | Packaging Details | Neutral Package or Fumigation Free |

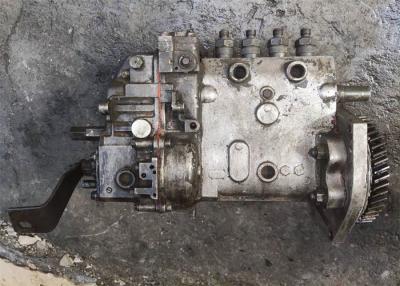

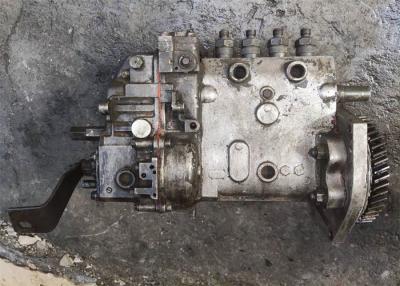

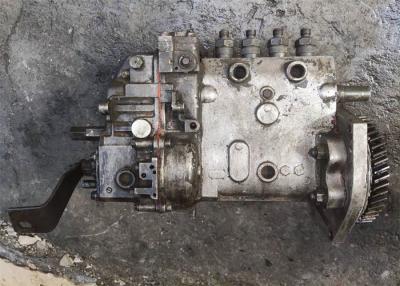

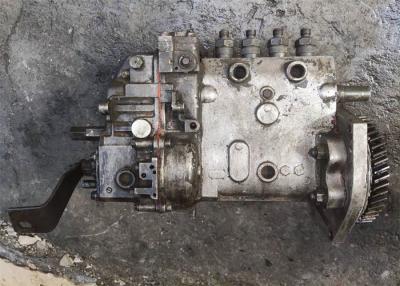

| Color | Same as pictures | Excavator model | PC60 - 7 |

| Material | Steel | Model Number | 4D95 |

| Supply Ability | 10 pieces | Brand Name | Komastu |

| Payment Terms | D/P, T/T | Type | Diesel Engine |

| Price | Negotiated | Delivery Time | 5 - 8 work days |

| Product name | Used Fuel Fuel Injection | Part number | 6204 - 73 - 1340 |

4D95 Used Fuel Injection Pump For Excavator PC60- 7 6204-73-1340 101495-3414

Specification

| Car name: Fuel Injection Pump | Model Number: 4D95 | |

| Quality: High quality | Engine type: Diesel | |

| Application: Excavator | Part code: 101495 - 3414 | |

| Cooling: Water cooling | Injection: Direct | |

Description

Adjustment of Fuel Pump Timing

Large engine

The timing can be altered by shifting the camshaft to the position relative to the crankshaft

For

adjustable

cam

type

engines

timing

can

be

altered

by

individual

cams

of

the

fuel

pumps.

Individual

unit

timing

checking

up

&

adjustment

required

for

movable

cam

type

engine

For

solid

camshaft

type,

it

is

only

required

for

checking

on

No.

1

unit.

How

will

you

check

pump

timing

if

no

TDC

mark

given

on

flywheel

?

In

Main

Engine

Make

a

marking

between

cross

head

and

guide

shoe

while

they

are

before

TDC

and

also

mark

at

the

flywheel.

Turn

the

crank

shaft

in

the

same

direction

until

the

crosshead

and

guide

shoe

are

at

the

previous

mark

(coincide)

Make

the

second

marking

on

the

fly

wheel.

We

got

two

marks

on

the

flywheel

mid

point

between

the

two

points

is

TDC.

Now

360º

can

be

divided

around

the

flywheel.

In

Auxiliary

Engine

Remove the fuel valve

Insert

the

rod

onto

the

piston

(mark

on

rod

and

flywheel)

Turn

crank

until

the

rod

previous

mark

Make

the

second

marking

on

the

fly

wheel

Mid

point

between

the

two

points

is

TDC

What

points

do

you

check

on

fuel

pump

when

overhaul

or

how

will

you

decide

?

Check

plunger

guide

wear

&

tear

Check

spring

(length

&

stiffness,

crack)

Plunger

&

barrel

wear

&

tear,

check

clearance

(5

microns

for

DO,

15

microns

for

HO)

by

dropping

the

plunger

into

the

barrel

it

fall

down

slowly

is

OK

Check

control

sleeve

and

rack

teeth

for

crack

Check

the

Delivery

valve

face

Check

‘O’

ring

of

fitted.

Metering

of

Fuel

Controlling

the

fuel

amount

in

two

ways,

by

means

of

a

helix

groove

on

the

plunger

or

by

means

of

control

valves.

The

quantity

of

fuel

delivered

is

regulated

by

the

vertical

length

of

the

helix

where

it

is

in

line

with

the

suction

port.

This

setting

may

be

altered

by

rotating

the

plunger.

In

stop

position,

the

vertical

slot

of

the

plunger

is

in

lined

with

the

spill

port

where

then

ports

are

opened

and

thus

no

injection

occurred.