| Price | Negotiated |

| MOQ | Negotiable |

| Delivery Time | 5 - 8 work days |

| Brand | Caterpillar |

| Place of Origin | USA |

| Model Number | 3406 |

| Packaging Details | Neutral Package or Fumigation Free |

| Payment Terms | D/P, T/T |

| Supply Ability | 3 pieces |

| Engine model | 3406 | Place of Origin | USA |

| Packaging Details | Neutral Package or Fumigation Free | Color | Same as pictures |

| Material | Steel | Model Number | 3406 |

| Supply Ability | 3 pieces | Car model | E245B |

| Brand Name | Caterpillar | Payment Terms | D/P, T/T |

| Type | Diesel Engine | Price | Negotiated |

| Delivery Time | 5 - 8 work days | Product name | Used Fuel Injection Pump |

| Quality | High quality | Part number | 104 - 4409 |

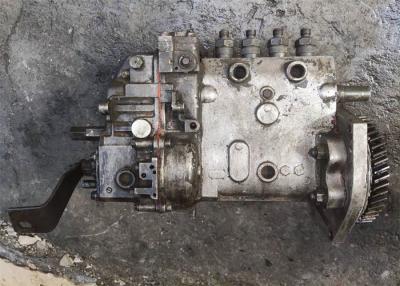

3406 Used Fuel Injection Pump For Excavator E245B 1044409 104 - 4409

Specification

| Part name | Engine fuel pump |

| Pump code | 490990 |

| Pump sensor code | 7E - 5888 |

| Condition | Original Used |

| Part number | 1044409 |

| Test staus | Normal |

| Engine Type | Diesel |

| Injection | Direct injection |

Description

What is a Fuel Injection Pump?

Related

Topics

Diesel

Fuel

Injection

Pump

Fuel

Injection

Pump

Fuel

Injection

Pump

Parts

Electric

Fuel

Injection

Pump

In

Line

Fuel

Injection

Pump

Electronic

Fuel

Injection

Pump

Fuel

Injection

Fuel

Pump

Fuel

injection

pumps

in

diesel

engines

operate

under

high

pressure.

A

device

that

pumps

fuel

into

gasoline

or

diesel

engine

cylinders

is

known

as

a

fuel

injection

pump.

The

pump

is

usually

driven

by

a

chain

or

toothed

timing

belt

that

is

motivated

by

the

gears

in

a

crankshaft.

This

system

is

also

linked

to

the

camshaft,

causing

them

to

be

intertwined.

In

traditional

four-stroke

engines,

it

rotates

at

half

the

speed

of

the

crankshaft

in

order

to

enable

the

correct

timing

of

the

injection

process.

This

occurs

as

the

cylinder's

compression

stroke

is

about

to

begin.

These devices are distinctly different from a fuel pump itself, which is primarily responsible for the flow of the fuel from its container or fuel tank. This is the part of the system in which fuel is brought out of the tank and pumped along a system of tubes to the engine block. The fuel injection pump then pushes the fuel inside the cylinders.

Fuel injection pumps need to operate in high-pressure environments in order to keep the system in full containment. In modern systems this is at the level of 15,000 psi or higher. For this reason, mechanics or engineers who work on these systems, especially diesel, take great care for personal safety. The fuel injection pump itself can possibly push fuel into the human body, causing serious harm to an individual.

In larger models, a concept known as in-line injection is the normal model. In this system, the pistons work with a throttle, which can produce varying power levels in the engine. All of the cylinders are rotated at once and the amount of fuel taken in is adjusted by a volume control method.