| Price | Negotiated |

| MOQ | Negotiable |

| Delivery Time | 5 - 8 work days |

| Brand | Mitsubishi |

| Place of Origin | Japan |

| Model Number | 6D16 |

| Packaging Details | Neutral Package or Fumigation Free |

| Payment Terms | D/P, T/T |

| Supply Ability | 3 pieces |

| Engine model | 6D16 | Place of Origin | Japan |

| Packaging Details | Neutral Package or Fumigation Free | Color | Same as pictures |

| Excavator model | SK330 - 6E | Material | Metal |

| Model Number | 6D16 | Supply Ability | 3 pieces |

| Brand Name | Mitsubishi | Payment Terms | D/P, T/T |

| Type | Diesel Engine | Price | Negotiated |

| Delivery Time | 5 - 8 work days | Product name | Used Fuel Injection Pump |

| Quality | High quality | Part number | ME440455 |

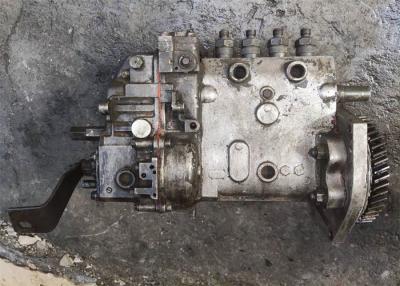

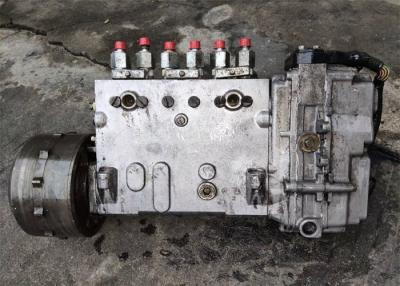

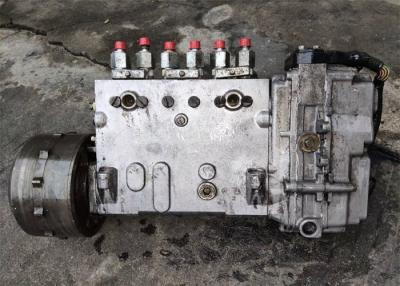

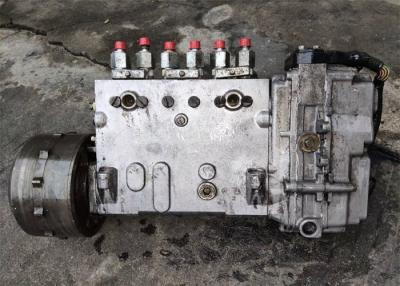

6D16 Used Fuel Injection Pump For Excavator HD1430 - 3 ME440455 101608 - 6353

Specification

| Car name: Fuel Injection Pump | Model Number: 6D16 | |

| Condition: Used | Engine type: Diesel | |

| Application: Excavator | Part code: 101608 - 6353 | |

| Cooling: Water cooling | Injection: Electric | |

Description

Functional Requirements of An Injection System

i. Accurate metering of the fuel injected per cycle: The quantity of the fuel metered should vary to met changing speed and load requirements of the engine.

ii. Timing the injection of the fuel correctly in the cycle: to obtain maximum power ensuring fuel economy and clean burning.

iii. Proper control of rate of injection: The desired heat release pattern is achieved during combustion

iv. Proper atomization of fuel into very fine droplets.

v. Proper spray pattern to ensure rapid mixing of fuel and air.

vi. Uniform distribution of fuel droplets throughout the combustion chamber.

vii.To supply equal quantities of metered fuel to all cylinders case of multi cylinder engines.

viii. No lag during beginning and end of injection i.e., to eliminate dribbling of fuel droplets into the cylinder Classification of Injection Systems.A fuel-injection system is required to inject and atomize fuel in to the cylinder of CI engines.

For producing the required pressure for atomizing the fuel either air or a mechanical means is used.

Thus the injection systems can be classified as:Air injector system

Solid injection systems

In this system the liquid fuel is injected directly into the combustion chamber without the aid of compressed air. Solid injection systems can be classified into four types.

1. Individual pump and nozzle system

2. Unit injector system

3. Common rail system

4. Distributor system

Components of Fuel Injection System

Fuel tank

Fuel filters: to prevent dust and abrasive particles from entering the pump and injectors thereby minimizing the wear and tear of the components.

Fuel feed pump: to supply fuel from the main fuel tank to the injection system.

Injection pump: to meter and pressurize the fuel for injection, Governor: to ensure that the amount of fuel injected is in accordance with variation in load.

Injector: to take the fuel from the p p um and distribute it in the combustion chamber by atomizing it into fine droplets.