| Price | Negotiated |

| MOQ | Negotiable |

| Delivery Time | 5 - 8 work days |

| Brand | Caterpillar |

| Place of Origin | USA |

| Model Number | 3306 |

| Packaging Details | Neutral Package or Fumigation Free |

| Payment Terms | D/P, T/T |

| Supply Ability | 5 pieces |

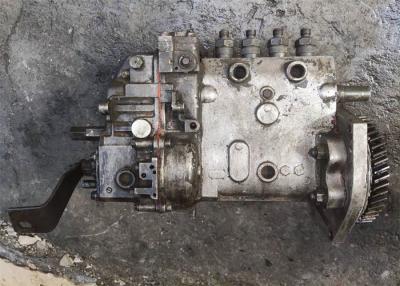

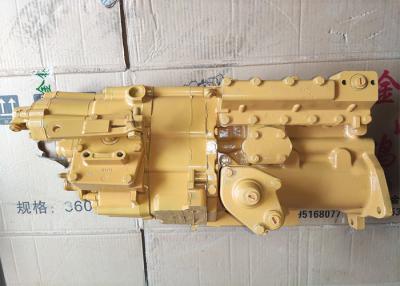

| Condition | Used | Engine model | 3306 |

| Place of Origin | USA | Packaging Details | Neutral Package or Fumigation Free |

| Color | Same as pictures | Excavator model | E330B |

| Material | Steel | Model Number | 3306 |

| Supply Ability | 5 pieces | Brand Name | Caterpillar |

| Payment Terms | D/P, T/T | Type | Diesel Engine |

| Price | Negotiated | Delivery Time | 5 - 8 work days |

| Product name | Used Fuel Injection Pump | Part number | 149 - 9851 |

3306 Used Fuel Injection Pump For Excavator E330B 149 - 9851

Specification

| Part name | Engine fuel pump |

| Pump code | 149 - 9851 |

| Pump number | 153 - 5739 |

| Condition | Original Used |

| Test staus | Normal |

| Engine Type | Diesel |

| Injection | Direct injection |

| Quality | High quality |

Description

Definition of Inline Injection Pump

Fuel

feeds

are

fuel

enter-exit

door,

there

are

three

fuel

feeds

inlet

feed,

used

as

fuel

entrance

from

the

tank

to

the

pump

output

feed,

used

as

the

fuel

exit

to

the

injector

in

high

pressure

conditions

return

feed,

used

to

drain

the

remaining

fuel

that

is

not

pressed

into

the

injector

And how does it work?

1. The outside mechanism of injection pump

Generally, there is a mini pump that is used to transfer fuel from the tank into the injection pump. This pump works mechanically, meaning it is driven by the crankshaft engine.

So, to run the fuel flow we need to crank the engine.

When

the

crankshaft

rotates,

the

mini

pump

will

send

diesel

fuel

from

the

tank

into

the

injection

pump

through

the

inlet

feed.

From

the

inlet

feed,

the

fuel

directly

fill

the

fuel

barrel

and

it

is

ready

to

be

pressed.

2. The injection pump mechanism

The

pump

camshaft

is

connected

to

the

engine

crankshaft,

so

that

when

the

engine

cranks

automatically

the

pump

camshaft

rotates.

This

rotation

will

move

the

plunger,

so

that

the

plunger

is

pressed

upwards

and

as

a

result

the

fuel

that

is

already

in

the

fuel

barrel

is

pressed

with

high

pressure

and

enters

the

injector.

When the cam has finished pressing the plunger, the plunger returns to the bottom position. This will reopen the fuel barrel chamber, so that the fuel from the inlet feed filling the fuel barrel directly.

3. Engine RPM setting mechanism

To

adjust

engine

RPM

on

conventional

diesel,

it

is

done

by

adjusting

the

amount

of

fuel

injected

by

the

injector.

In this case, the control is located in the fuel barrel. How much the amount of fuel in the fuel barrel when it is pressed will affect the engine RPM.

it is the task of rack and pinion. These two components will regulate the amount of fuel in the fuel barrel by regulating fuel disposal through the return feed.

The

amount

of

fule

is

less

(Low

RPM)

The

amount

of

fuel

is

more

(high

RPM)

So, there is a fuel path inte plunger from the fuel barrel leading to the return feed.

This path is made with a certain slope, so that when the angle of the plunger is rotated, it will affect the amount of fuel contained in the fuel barrel

To be clearer you can see the picture (viewed from side)

a. when low RPM

The amount of pressed fuel is lower, so the angle of plunger can be seen from the picture.

2. when high RPM

The amount of pressed fuel is more, so the angle of plunger can be seen from the picture.