| Price | Negotiated |

| MOQ | Negotiable |

| Delivery Time | 5 - 8 work days |

| Brand | Caterpillar |

| Place of Origin | USA |

| Model Number | C6.4 |

| Packaging Details | Neutral Package or Fumigation Free |

| Payment Terms | D/P, T/T |

| Supply Ability | 5 pieces |

| Engine model | C6.4 | Place of Origin | USA |

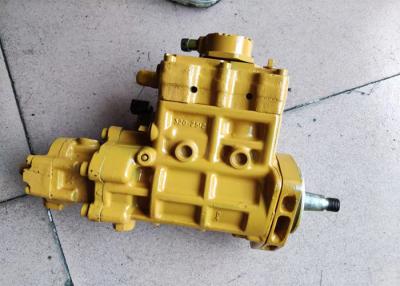

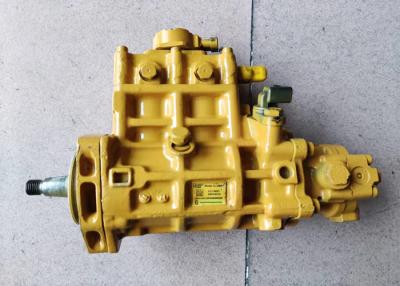

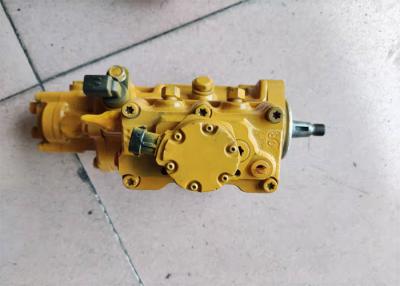

| Packaging Details | Neutral Package or Fumigation Free | Color | Same as pictures |

| Excavator model | E320D | Material | Steel |

| Model Number | C6.4 | Supply Ability | 5 pieces |

| Brand Name | Caterpillar | Payment Terms | D/P, T/T |

| Type | Diesel Engine | Price | Negotiated |

| Delivery Time | 5 - 8 work days | Product name | Used Fuel Injection Pump |

| Quality | High quality | Part number | 3264635 |

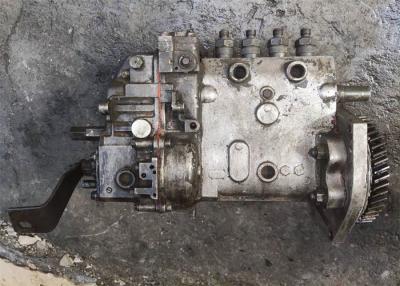

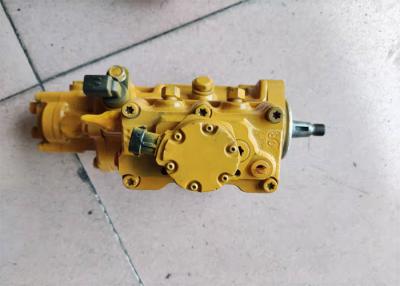

C6.4 Used Fuel Injection Pump For Excavator E320D 3264635 326 - 4635

Specification

| Part name | Engine fuel pump |

| Pump code | 317 - 8021 |

| Pump sensor code | 2641A312 |

| Condition | Original Used |

| Part number | 326 - 4635 |

| Test staus | Normal |

| Engine Type | Diesel |

| Injection | Electric injection |

Description

Fuel Injection Pump Working Principle in Diesel Engine

There

are

two

types

of

injection

pumps

on

conventional

diesel

engines,

inline

pump

and

distributor

pump.

We have discussed the difference between the two types of pumps in the previous article, you can access these 3 types of fuel injection pump in diesel engines.

in this article, we will discuss in detail about the inline injection pump.

How does it work ? what are the components? we will discuss it all.

Definition of Inline Injection Pump

Inline injection pump is a high pressure pump on a diesel engine that is used to increase diesel fuel pressure up to 18,000 PSI individually.

That is, each injector will be served by a plunger unit.

It can be said, in a 4 cylinder diesel engine there are 4 injectors and 4 plungers.

The

main

characteristic

of

the

inline

injection

pump,

lies

in

the

configuration

of

each

plunger.

Each

plunger

is

placed

in

line

above

a

camshaft

pump.

That's where the name inline pump is taken. In addition to being called an inline pump, this type is also known as the individual pump because, as explained above, this type uses one plunger for each cylinder.

The main component of the inline injection pump. There are 5 main components in the inline injection pump,

Camshaft

pump

Plunger

Fuel

barrel

Fuel

feed

Rack

and

pinion

The

camshaft

pump

is

used

to

drive

the

plunger

in

order

to

press

the

fuel.

While

the

fuel

barrel,

is

the

place

to

hold

fuel

that

will

be

pressed

to

the

injector.

This is the configuration, the plunger is located above the camshaft and the fuel barrel is located above the plunger.

Rack and pinion is a mechanism to regulate the amount of fuel in the fuel barrel. This mechanism will regulate the diesel engine RPM.