| Price | Negotiated |

| MOQ | Negotiable |

| Delivery Time | 5 - 8 work days |

| Brand | DENSO |

| Place of Origin | Japan |

| Model Number | 6D125 |

| Packaging Details | Neutral Package or Fumigation Free |

| Payment Terms | D/P, T/T |

| Supply Ability | 5 pieces |

| Engine model | 6D125 | Place of Origin | Japan |

| Plunger head | Six | Machine model | PC400 - 5 / D6 - 11 |

| Packaging Details | Neutral Package or Fumigation Free | Color | Grey |

| Model Number | 6D125 | Supply Ability | 5 pieces |

| Car model | Komastu | Weight | 28kg |

| Brand Name | DENSO | Payment Terms | D/P, T/T |

| Price | Negotiated | Delivery Time | 5 - 8 work days |

| Quality | High quality | Application | Excavator or Bulldozer |

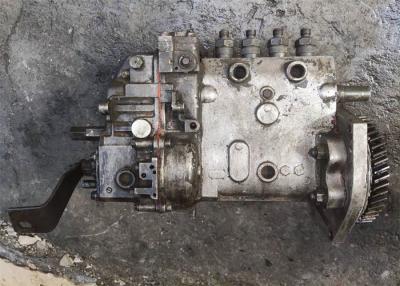

6D125 Used Fuel Injection Pump 6151 - 73 - 1240 For Excavator PC400 - 5 D6 - 11

Specification

| Part name | Engine fuel pump |

| Part code | 6151 - 73 - 1240 |

| Pump number | 191000 - 96208 |

| Condition | Original Used |

| Cylinder | Six |

| Test staus | Normal |

| Engine Type | Diesel |

| Injection | Direct injection |

Description

Is the fuel pump part of the engine?

The engine driven fuel pump is part of the Excavator fuel system, one of the most important elements of the fuel system, like to any other internal combustion engine equipped vehicle.

What is the pressure of a fuel pump?

The

capability

of

the

high

pressure

gear

stage

of

the

pump

in

pressure

is

850

to

900

psi

(pounds

per

square

inches),

and

in

volume

displacement

50

to

60

U.

S.

Gallons,

or

13.000

litters

per

hour

at

maximum

nominal

operating

speed

of

the

pump

at

6250

rpm

for

this

pump,

and

when

the

engine

operates

to

take

off

power.

How a mechanical pump works?

A

mechanical

fuel

pump

is

driven

by

the

camshaft

,

or

by

a

special

shaft

driven

by

the

crankshaft

.

As

the

shaft

turns,

a

cam

passes

under

a

pivoted

lever

and

forces

it

up

at

one

end.

The other end of the lever, which is linked loosely to a rubber diaphragm forming the floor of a chamber in the pump, goes down and pulls the diaphragm with it.

When the lever pulls the diaphragm down, it creates suction that draws fuel along the fuel pipe into the pump through a one-way valve .

As the revolving cam turns further, so that it no longer presses on the lever, the lever is moved back by a return spring , relaxing its pull on the diaphragm.

The loosely linked lever does not push the diaphragm up, but there is a return spring that pushes against it.

The diaphragm can move up only by expelling petrol from the chamber. The petrol cannot go back through the first one-way valve, so it goes out through another one leading to the carburettor.

The carburettor admits petrol only as it needs it, through the needle valve in its float chamber.