| Price | Negotiable |

| MOQ | Negotiable |

| Delivery Time | 15-20 Work day |

| Brand | UVIR |

| Place of Origin | China |

| Certification | CE & ROHS |

| Model Number | IRP011 |

| Packaging Details | Each lamp in a cylinder .Then in a professional plywood box |

| Payment Terms | L/C, T/T, Western Union, MoneyGram |

| Place of Origin | China | Size | 11*23mm |

| Packaging Details | Each lamp in a cylinder .Then in a professional plywood box | Reflector | Gold |

| Material | Quartz Tube | Model Number | IRP011 |

| Heating length | 740mm | Certification | CE & ROHS |

| Brand Name | UVIR | Payment Terms | L/C, T/T, Western Union, MoneyGram |

| Type | H | Price | Negotiable |

| Delivery Time | 15-20 Work day | Minimum Order Quantity | Negotiable |

| Voltage | 400V | Power | 5400W |

| Total length | 1200mm |

IRP011 short wave 400V 5400W 11*23mm infrared heater lamp CD10/SM 102 Heating accessories

Main

components

of

a

twin

tube

infrared

lamp:

1.

Fused

silica

2.

Tungsten

heating

elements

3.

Supports

for

heating

wire

4.

End

plate

and

ceramic

end

5.

Wire

leads

6.

Reflective

layer.

Shown:

gold

layer

7.

Proprietary

gas

composition.

Product parameter

| Type | IRP011 infrared lamp for PrintingMachine |

| Size | 11*23mm |

| Coating | Gold |

| Power | 400V |

| Voltage | 5400W |

| OEM/ODM | many types of voltage,wattage,length,base,cables,universal burning position is available |

Products detail

IRP Infrared lamp for Printing Machine

| Dryer |

UVIR Code |

Lamp Code |

Energy | Volts | Watts |

Total Length |

Tube

Corss Section |

Constr uction |

Dryer Detail |

| SM52 | IRP001 | SM52-SW-A | short wave | 415 | 3300 | 712 | 11*23 | B |

Grafix Heidelberg SM52 |

| Heidelberg MO | IRP002 | HMO-SW-A | short wave | 415 | 3300 | 740 | 11*23 | B |

Grafix Heidelberg MO |

| Heidelberg MO | IRP003 | HMO-MW-B | med. wave | 415 | 1800 | 740 | 15*33 | B |

Grafix Heidelberg MO |

| SM72 | IRP004 | SM72-SW-A | short wave | 415 | 3500 | 800 | 15*33 | B |

Grafix Heidelberg 72 |

| SM72 | IRP005 | SM72-MW-B | med. wave | 415 | 1900 | 800 | 15*33 | B |

Grafix Heidelberg 72 |

| SM102 - pre 97' | IRP006 | SM102-SW-A | short wave | 415 | 3500 | 1100 | 11*23 | A |

Heidelberg SM102(pre1997) Grafix Part:2130012 |

| SM102 - pre 97' | IRP007 | SM102-MW-B | med. wave | 415 | 2500 | 1100 | 15*33 | B |

Heidelberg SM102(pre1997) Grafix Part:2130011 |

|

CD74/SM74/ MAN 500 |

IRP008 | SM74-SW-C | short wave | 400 | 6950 | 900 | 11*23 | H |

Drystar-Heidelberg SM74/CD74(post 1997) |

|

CD74/SM74/ MAN 500 |

IRP009 | SM74-FMW-B | fast. med. | 480 | 4200 | 820 | 15*33 | B |

Grafix

Heldelberg SM74 post 1997 |

|

CD74/SM74/ MAN 500 |

IRP010 | MANGX-FMW-B | fast. med. | 415 | 4200 | 820 | 15*33 | B |

Grafix

SHS

MAN Roland 500 |

| CD102/SM102 | IRP011 | SM102-SW-C | short wave | 400 | 5400 | 1200 | 11*23 | H | Drystar |

| CD102/SM102 | IRP012 | SM102-FMW-B | fast. med. | 180 | 6000 | 1120 | 15*33 | B |

Grafix

SHS

Heidelberg 102 post 1997 |

| CD102/SM102 | IRP013 | SM102-FMW-B-3000 | fast. med. | 400 | 6200 | 1160 | 15*33 | B |

Drystar

3000 Heidelberg SM102/CD102 /SM10(post) |

| SM105XL | IRP014 | SM105XL-FMW-B | fast. med. | 400 | 6200 | 1160 | 15*33 | B |

Drystar

Heidelberg SM105XL(past 2007 ) |

| XL75 | IRP016 | XL75 | short wave | 400 | 3500 | 900 | 11*23 | B | XL75 |

IRP infrared lamp application

1.Infrared

Heating

For

Plastics

Process

IR

drying

of

coatings

on

plastics

IR

stretching

or

shrinking

plastics

IR

Heating

For

Plastic

Packaging

IR

heating

for

blow

moulding

of

PET

bottles

2.Infrared

Heating

For

Printing

Industry

IR

curing

ink

on

cloth

IR

drying

for

inkjet-based

CTP

plates

IR

drying

of

printing

products

,such

as

using

in

banners

machine

Why choose us

1. Lamps are approved by CE and RoHS.

2. Implement strict quality system according to ISO9001.

3. All lamps are tested one by one before delivery out from our factory.

4. You will get 1 year warranty for our UV lamps,free replacements or repairment service if they fail to work during warranty period.

5. Punctual delivery time, samples order delivery within 5 working days, bulk order delivery within 25 days.

6. Dependable after sales service

7. ODM and OEM service.

8. Low MOQ limitation

9. 7*24service, any of your questions will be replied within 24 hours

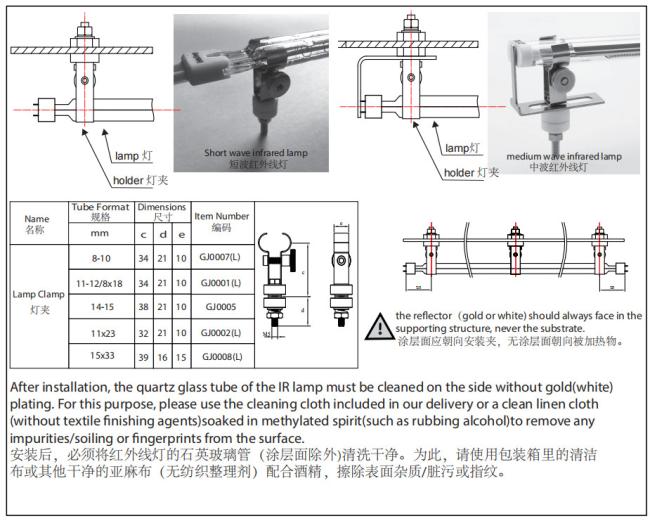

Installation

Turn off all electrical power to your lamps when stalling or replacing them.

Rated voltage:

Infrared

emitters

should

never

be

operated

with

more

than

the

maximum

rated

voltage

specified.

Any

longer

operation

at

excess

voltage(V>

1

10%

of

the

rated

voltage)

may

result

in

destruction

of

the

infrared

emitter.

Installation:

Transport