| Price | Negotiable |

| MOQ | Negotiable |

| Delivery Time | 15-20 Work day |

| Brand | UVIR |

| Place of Origin | Guangdong, China |

| Certification | CE & ROHS |

| Model Number | IRP007 |

| Packaging Details | Each lamp in a cylinder .Then in a professional plywood box |

| Payment Terms | L/C, T/T, Western Union, MoneyGram |

| Place of Origin | Guangdong, China | Packaging Details | Each lamp in a cylinder .Then in a professional plywood box |

| Material | Quartz | Model Number | IRP007 |

| Heating length | 1020mm | Certification | CE & ROHS |

| Brand Name | UVIR | Payment Terms | L/C, T/T, Western Union, MoneyGram |

| Type | B | Price | Negotiable |

| Delivery Time | 15-20 Work day | Tube diameter | 15*33mm |

| Minimum Order Quantity | Negotiable | Voltage | 415V |

| Coating | Gold | Power | 2500W |

| Total length | 1100mm |

IRP007 415V 2500W Twin tube Medium wave infrared emitters for Heidelberg SM102(pre1997)

The Advantages Of UVIR Heat Lamp

Carbon fiber heat lamp

1.High-priced imported carbon fiber filament.

2.The finished filament is smooth and does not fluff.

3.The optimum power and maximum longevity.

Guartz glass tube

1.High quality high-temperature quartz glass.

2.Long serving life: over 5000 hours.

3.nontoxic and peculiar smell, no risk of contamination over environment or target object to be heated.

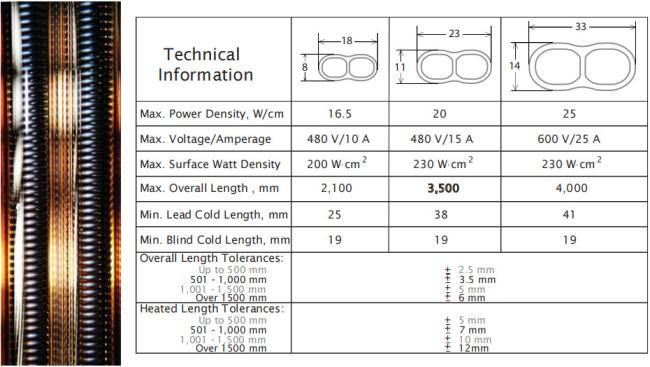

Technical Description

TWIN TUBE MEDIUM-WAVE IR L AMPS

Product details

| Type | IRP007 infrared lamp for PrintingMachine |

| Size | 11X23mm |

| Coating | Gold |

| Power | 230V |

| Voltage | 2500W |

| OEM/ODM | many types of voltage,wattage,length,base,cables,universal burning position is available |

IRP Infrared lamp for Printing Machine

| Dryer |

UVIR Code |

Lamp Code |

Energy | Volts | Watts |

Total Length |

Tube

Corss Section |

Constr uction |

Dryer Detail |

| SM52 | IRP001 | SM52-SW-A | short wave | 415 | 3300 | 712 | 11*23 | B |

Grafix Heidelberg SM52 |

| Heidelberg MO | IRP002 | HMO-SW-A | short wave | 415 | 3300 | 740 | 11*23 | B |

Grafix Heidelberg MO |

| Heidelberg MO | IRP003 | HMO-MW-B | med. wave | 415 | 1800 | 740 | 15*33 | B |

Grafix Heidelberg MO |

| SM72 | IRP004 | SM72-SW-A | short wave | 415 | 3500 | 800 | 15*33 | B |

Grafix Heidelberg 72 |

| SM72 | IRP005 | SM72-MW-B | med. wave | 415 | 1900 | 800 | 15*33 | B |

Grafix Heidelberg 72 |

| SM102 - pre 97' | IRP006 | SM102-SW-A | short wave | 415 | 3500 | 1100 | 11*23 | A |

Heidelberg SM102(pre1997) Grafix Part:2130012 |

| SM102 - pre 97' | IRP007 | SM102-MW-B | med. wave | 415 | 2500 | 1100 | 15*33 | B |

Heidelberg SM102(pre1997) Grafix Part:2130011 |

|

CD74/SM74/ MAN 500 |

IRP008 | SM74-SW-C | short wave | 400 | 6950 | 900 | 11*23 | H |

Drystar-Heidelberg SM74/CD74(post 1997) |

|

CD74/SM74/ MAN 500 |

IRP009 | SM74-FMW-B | fast. med. | 480 | 4200 | 820 | 15*33 | B |

Grafix

Heldelberg SM74 post 1997 |

|

CD74/SM74/ MAN 500 |

IRP010 | MANGX-FMW-B | fast. med. | 415 | 4200 | 820 | 15*33 | B |

Grafix

SHS

MAN Roland 500 |

| CD102/SM102 | IRP011 | SM102-SW-C | short wave | 400 | 5400 | 1200 | 11*23 | H | Drystar |

| CD102/SM102 | IRP012 | SM102-FMW-B | fast. med. | 180 | 6000 | 1120 | 15*33 | B |

Grafix

SHS

Heidelberg 102 post 1997 |

| CD102/SM102 | IRP013 | SM102-FMW-B-3000 | fast. med. | 400 | 6200 | 1160 | 15*33 | B |

Drystar

3000 Heidelberg SM102/CD102 /SM10(post) |

| SM105XL | IRP014 | SM105XL-FMW-B | fast. med. | 400 | 6200 | 1160 | 15*33 | B |

Drystar

Heidelberg SM105XL(past 2007 ) |

| XL75 | IRP016 | XL75 | short wave | 400 | 3500 | 900 | 11*23 | B | XL75 |

IRP infrared lamp application

1.Infrared

Heating

For

Plastics

Process

IR

drying

of

coatings

on

plastics

IR

stretching

or

shrinking

plastics

IR

Heating

For

Plastic

Packaging

IR

heating

for

blow

moulding

of

PET

bottles

2.Infrared

Heating

For

Printing

Industry

IR

curing

ink

on

cloth

IR

drying

for

inkjet-based

CTP

plates

IR

drying

of

printing

products

,such

as

using

in

banners

machine

OEM Service

We can advise the customer choosing the right heat lamp for the specific application. Furthermore, the Technical Department can design the right lamp based on the customer’s specific technical instructions.

We can product many sizes and types heat lamp according to customers requirement, and so on.If have drawing is beat, then we can do samples for you.

Safety Instructions

Potentially explosive atmospheres

Infrared lamps are not intended for use in potentially explosive or combustible atmospheres.

Danger to eyes and skin

Do not stare at the IR lamp while in operation

Do not touch the IR lamp while in operation

Power supply lines

The

power

supply

lines

must

not

be

routed

in

bundles.

Routing

in

bundles

increases

the

risk

of

overheating

at

considerably

lower

temperatures.

The

power

supply

lines

installed

are

not

designed

to

withstand

heavy

vibration

or

cyclic

movement.

If

the

infrared

lamps

are

to

be

moved

by

a

device,

the

power

supply

lines

must

be

installed

on

terminals

that

move

along

with

the

lamp.

Suitable

leads

for

the

power

supply

should

then

be

installed

from

there.

Gold reflector/White reflector

The

temperature

of

the

gold

reflector

should

not

exceed

600°C

in

any

operating

condition

to

prevent

irreversible

damage

to

the

rflection

properties

of

the

gold.

The

temperature

of

the

white

reflector

should

not

exceed

900°C

in

any

operating

condition

to

prevent

irreversible

damage

to

the

reflection

properties

of

the

white

coating.

Pinch seal/ ceramic end cap

The

temperature

of

the

pinch

seals

and

the

ceramic

caps

should

not

exceed

250°C.

If

the

pinch

seal

and

the

ceramic

caps

overheat,

the

infrared

emitter

will

fail

prematurely,

the

pinch

seal

will

break

and

potential

danger

may

arise

from

exposed

live

parts.

Quartz glass tube

To

avoid

damaging

the

quartz

glass

tube,

the

temperature

of

the

tube

must

not

exceed:

700°C

for

shortwave

emitters/800°C

for

carbon

emitters/900°C

for

medium-wave

emitters