Single Row Excavator Bearing Deep Groove AC5836

Product Overview

High-quality single row excavator bearing with deep groove design, featuring low noise operation and 50 HRC hardness rating.

Key Features

Bearing Number:

AC5836

Precision Rating:

P0, P5, P4

Bore Size:

5 - 1000 mm

Weight:

5KG

Material:

Chrome Steel

Hardness:

50-60 HRC

Available Materials:

Chrome Steel, Stainless Steel, Ceramics

Stock:

1000pcs

Model Specifications

| Model Number |

Internal Diameter (mm) |

External Diameter (mm) |

Height (mm) |

| AC5836 | 289 | 355 | 34 |

| AC5033 | 250 | 330 | 38 |

| AC463240 | 230 | 320 | 40 |

| AC4629 | 230 | 290 | 27 |

| AC4531 | 225 | 315 | 40 |

| AC423040 | 210 | 300 | 40 |

| AC4630 | 230 | 300 | 35 |

| AC6037 | 300 | 370 | 33 |

| AC4631 | 230 | 310 | 39 |

| AC523438-1 | 260 | 340 | 38 |

Deep Groove Ball Bearing Design

Deep groove ball bearings are the most versatile bearing type, available in various seal, shield, and snap-ring configurations. The bearing ring grooves feature circular arcs slightly larger than the ball radius for optimal performance.

Balls maintain point contact with raceways (elliptical when loaded), with inner and outer ring shoulders of equal height. These bearings accommodate radial, axial, or composite loads while delivering high-running accuracy and high-speed operation. Standard pressed steel retainers are used, with machined cages available for high-speed or large-diameter applications.

Excavator Bearing Installation Guidelines

Proper excavator bearing installation and removal methods depend on bearing structure, dimensions, and component compatibility. Installation pressure must be applied directly to the bearing ring tight end surface, never through rolling elements, to prevent surface indentation that compromises performance.

Bearings with cages, seals, dust covers, and other delicate components require careful handling to avoid deformation during installation or removal.

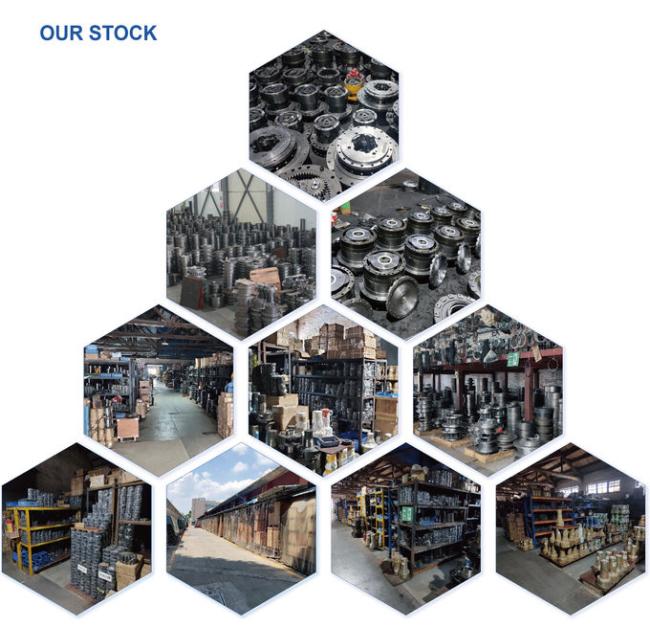

Our Stock & Delivery

We maintain over 4000 square meters of three-dimensional warehouse space plus 2000 square meters of outdoor storage, ensuring ample inventory and rapid response to customer requirements. Fast delivery is our competitive advantage.

Frequently Asked Questions

What products do you provide?

We supply excavator final drive and swing drive motors, reducer gearboxes, and their component parts.

How long is the warranty period?

We provide a 3-6 month warranty with free maintenance spare parts during the warranty period.

Can I order samples for testing?

Yes, sample orders are available for testing purposes.

How do I place an order?

Provide the model and quantity you need, and we'll issue a proforma invoice. Goods are prepared after payment receipt, with preparation time depending on order specifics.

Do you have your own factory?

Yes, we operate our own factory with 22 years of experience in excavator gear manufacturing.