| Price | 100.00-200.00USD |

| MOQ | 1 |

| Delivery Time | 1-2days |

| Brand | TGFQ |

| Place of Origin | China |

| Model Number | AC4631 |

| Packaging Details | NNER PACKING: Wrap by plastic film, clear label for each item. OUTER PACKING: Carton or Plywood Case PACKING SIZE: Depend on packing type |

| Payment Terms | L/C, T/T, D/P, D/A |

| Supply Ability | 1000 pcs / month |

| Place of Origin | China | Apply to | Gearbox |

| Cage | Steel Cage/copper Cage/nylon Cage | Packaging Details | NNER PACKING: Wrap by plastic film, clear label for each item. OUTER PACKING: Carton or Plywood Case PACKING SIZE: Depend on packing type |

| Product Name | planetary gearbox bearings | Model Number | AC4631 |

| Supply Ability | 1000 pcs / month | Brand Name | TGFQ |

| Payment Terms | L/C, T/T, D/P, D/A | Applicable Industries | Machinery Repair Shops, Energy & Mining |

| Price | 100.00-200.00USD | Delivery Time | 1-2days |

| Number of Row | Single row | Minimum Order Quantity | 1 |

| Structure | Deep Groove | Lubriion | Grease |

230X310X38 Heavy Duty Excavator planetary gearbox bearings AC-4631 AC4631 are engineered for superior performance in demanding excavator applications.

| Bearing Number | AC4631 |

| Precision Rating | ABEC 1, 3, 5, 7, 9 |

| Dimensions | 230×310×38 mm |

| Precision Grade | P0, P6, P5, P4, P2 (all available) |

| Material | Chrome Steel |

| Hardness | 60-50 HRC |

| Application | Excavator |

| Stock Availability | 1000 pcs |

Tapered roller bearings consist of four interdependent components: the cone (inner ring), the cup (outer ring), the tapered rollers (rolling elements), and the cage (roller retainer). These bearings are uniquely designed to manage both thrust and radial loads between rotating and non-rotating members. The steeper the cup angle, the greater the bearing's ability to handle thrust loads.

Proper installation and removal methods for excavator bearings should be based on bearing structure, size, and component compatibility. During installation and removal, pressure should be applied directly to the bearing ring's tight end surface, never through the rolling elements. Applying pressure through rolling elements can cause surface indentations that affect bearing performance and may lead to premature failure. Bearings, cages, seals, dust covers, and other components are susceptible to deformation, so pressure must not be applied to these delicate parts during installation or removal.

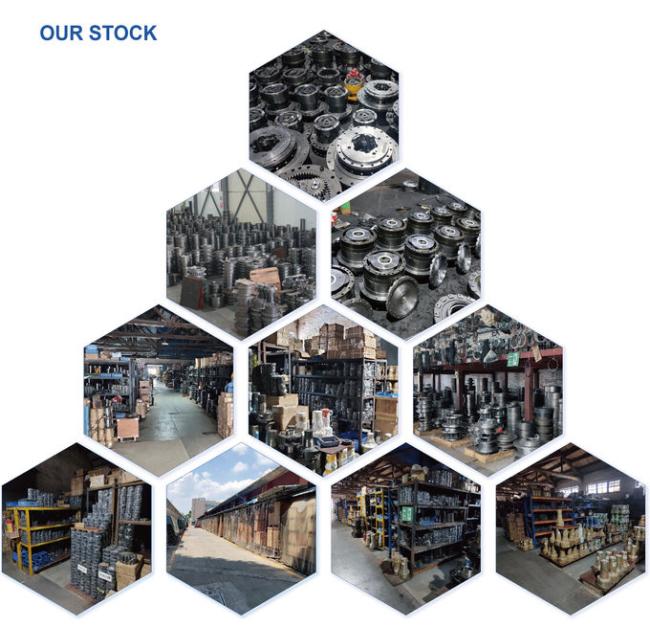

We maintain extensive warehousing facilities with over 4,000 square meters of three-dimensional warehouse space and an additional 2,000 square meters of outdoor storage. This ensures adequate inventory levels and enables rapid response to customer requirements. Fast delivery is one of our key competitive advantages.

We supply excavator final drive and swing drive motors, reducer gearboxes, and all related components and parts.

We offer a 3 to 6 month warranty period, during which we provide maintenance spare parts free of charge.

Yes, we welcome sample orders for testing and evaluation purposes.

Please provide the model and quantity you require. We will issue a proforma invoice, and upon payment confirmation, we will prepare your order. Preparation time varies based on order complexity and volume.

Yes, we operate our own factory with 22 years of specialized experience in the excavator gear industry.