Excavator Bearing Installation Guidelines

Proper installation and removal methods for excavator bearings should be determined based on the bearing structure, size, and compatibility with excavator components. During installation, pressure should be applied directly to the tight end surface of the excavator bearing ring, not transmitted through the bearing rolling elements. Applying pressure through rolling elements can create indentations on the bearing surface, affecting normal operation and potentially causing bearing damage. Excavator bearing cages, seals, dust covers, and other components are prone to deformation, so installation or removal pressure should never be applied to these parts.

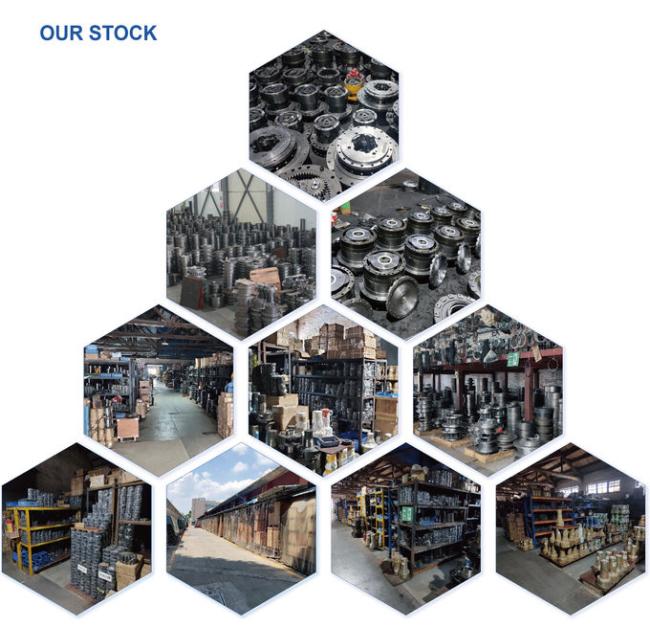

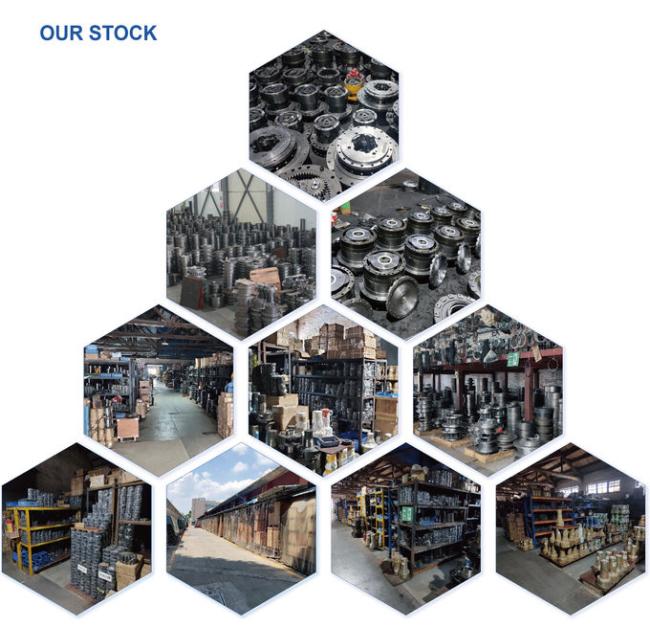

Our Warehouse Capacity

We maintain over 4000 square meters of three-dimensional warehouse space and an additional 2000 square meters of outdoor warehouse facilities. This extensive storage capacity ensures we maintain sufficient inventory levels and can respond rapidly to customer requirements. Fast delivery is one of our key competitive advantages.

Frequently Asked Questions

What products and services do you provide?

We supply excavator final drive and swing drive motors, reducer gearboxes, and their component parts.

How long is the warranty period?

We offer a 3-6 month warranty period and provide free maintenance spare parts during the warranty coverage.

Can I order samples for testing?

Yes, we welcome sample orders for product testing and evaluation.

What is the ordering process?

Please provide the model and quantity you require, and we will issue a proforma invoice. Goods preparation begins after payment receipt, with timing dependent on order specifics.

Do you have your own manufacturing facility?

Yes, we operate our own factory with 22 years of production experience in the excavator gear industry.