| Price | $5000-$150000 |

| MOQ | 1unit |

| Delivery Time | 30days |

| Brand | WINLEY |

| Place of Origin | CHINA |

| Certification | UL,cUL,CE,ISO |

| Model Number | S-3000/25 |

| Packaging Details | Plywood case |

| Payment Terms | T/T |

| Supply Ability | 1000set/month |

| Place of Origin | CHINA | Cooling method | ONAN |

| Packaging Details | Plywood case | Standard | ASNI/IEEE C57.12.00 |

| Secondary Voltage | 4160Y/2400 | Model Number | S-3000/25 |

| Supply Ability | 1000set/month | Certification | UL,cUL,CE,ISO |

| Insulation class | A (105℃) | Brand Name | WINLEY |

| Payment Terms | T/T | Vector Group | Dyn1 |

| Type | pad mounted,radial feed | Price | $5000-$150000 |

| Delivery Time | 30days | Capacity | 3000 KVA |

| Minimum Order Quantity | 1unit | Primary Voltage | 24.94KV |

Three Phase Pad Mounted Transformer 3000Kva 24940V To 4160Y/2400 UL Certified

The three phase pad mounted transformers we produce have obtained UL certification, with capacities ranging from 30 to 5500kVA and voltages up to 34.5kV. Our products are exported to North America the Philippines and other places in large quantities.

Main data

| Particulars | Unit | Specification | Remark |

| Type | ~ | pad mounted,radial feed | |

| Rated capacity | kVA | 3000 | |

| No. of Phase | ~ | 3 | |

| Primary voltage | V | 24940 | delta |

| Primary termination | ~ | 25kV class Porcelain bushing | live front |

| Secondary voltage | V | 4160Y/2400 | Wye-N |

| Secondary connection | ~ | 5kV class Porcelain bushing | live front |

| Tapping type | ~ | off-circuit tapping | |

| Tapping range | % | ±2*2.5% | |

| Cooling method | ~ | ONAN | |

| Rated frequency | Hz | 60 | |

| Vector group | ~ | Dyn1 | |

| Insulation class | ~ | A (105℃) | |

| Temperature rise | K | 65 | |

| Off-load loss | W | 2810 | with 10% tolerance |

| On-load loss (85℃) | W | 25796 | |

| Impedance | % | 5.0~7.5 | |

| Winding material | ~ | Cu | |

| Core material | ~ | silicon steel | |

| Cooling material | Mineral oil | ||

| Housing material | ~ | coated steel | |

| Service condition | ~ | indoor or outdoor | |

| Sea level | M | ≤1000 | |

| Standard | ~ | ASNI/IEEE C57.12.00 |

Standard Features

•

60

Hz

operation.

•

65°C

average

winding

rise.

•

Radial

&

loop

feed

arrangements.

•

Dead

and

live

front

type

of

HV

terminals.

•

HV

BIL

45

–

150

kV

(Dead

Front)

200

kV

(Live

Front).

•

LV

BIL

30

–

60

kV.

•

Three-point

latching

of

low-voltage

door.

•

High-voltage

door,

which

can

be

opened

only

after

the

low-voltage

door

is

opened.

•

Rigid

steel

partition.

•

Transformer

tank

welded

from

cover

to

base.

•

Permanent

nameplate.

•

One-inch

NPT

pipe

cap

filling

provision.

•

ANSI

tank

ground

pads.

•

One-inch

drain

valve

and

sampler.

•

Automatic

pressure-relief

valve

(35

SCFM).

•

Tap

changer

with

(2)

2.5%

full

capacity

taps

above

and

below

nominal.

•

One

10”x18”

(or

14”x25”)

hand

hole

in

transformer

tank

cover.

•

Painted

olive-green

color

(Munsell

7GY

3.29/1.5).

•

Designed,

manufactured

and

tested

in

accordance

with

the

latest

ANSI

standards

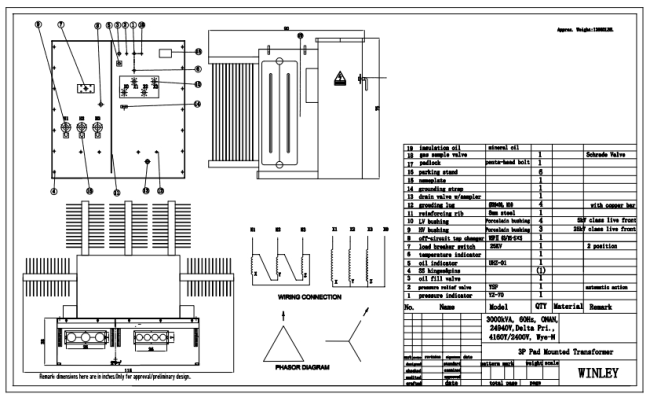

Technical drawings

Product structure

1)The

transformer

part

and

the

control

cabinet

part

of

the

United

States

variation,

of

which

the

transformer

part

is

a

fully

sealed

structure,

and

the

insulating

oil

can

be

two

types

of

high

ignition

point

oil

or

ordinary

oil.

2)The

control

cabinet

is

divided

into

a

high-voltage

room

and

a

low-voltage

room.

3)The

high-voltage

room

is

equipped

with:

high-voltage

cable

plug,

lightning

arrester,

load

switch

operating

handle,

non-excitation

tap

switch

handle,

plug-in

fuse,

pressure

release

valve,

thermometer,

pressure

gauge,

oil

Position

gauges,

oil

filling

plugs,

oil

drain

valves,

etc.,

load

switches,

off-excitation

tap

changers,

plug-in

fuses,

etc.

are

all

immersed

in

transformer

oil

together

with

the

transformer

core.

The

high-voltage

cable

and

the

transformer

are

connected

by

elbow

cable

connectors.

4)The

low-voltage

side

can

be

installed

with

air

circuit

breakers,

current

transformers,

as

well

as

electric

energy

meters,

ammeters

and

voltmeters,

and

output

circuits

and

capacitance

compensation

devices

can

be

configured

according

to

user

needs.

Specification

| PRODUCT SPECIFICATION | ||||||||

|

Rated

Power (KVA) |

High

Voltage (KV) |

Low

Voltage (V) |

No-load

Loss (W) |

On-load

Loss (W) |

Height (mm) |

Depth (mm) |

Width (mm) |

Weight (kg) |

| 75 |

34.5KV 4.160KV 12.47KV 13.2KV 13.8KV 24940GrdY/14400 1247Grdy/7200 4160GrdY/2400 or others |

277V 347V 480V 600V 120/240V 208GrdY/120 415GrdY/240 480GrdY/277 600Y/347 |

180 | 1250 | 1430 | 910 | 1930 | 645 |

| 150 | 280 | 2200 | 1530 | 980 | 1510 | 989 | ||

| 300 | 480 | 3650 | 1680 | 1080 | 1660 | 1415 | ||

| 500 | 680 | 5100 | 1790 | 1160 | 1810 | 1905 | ||

| 750 | 980 | 7500 | 2030 | 1300 | 2030 | 2755 | ||

| 1000 | 1150 | 10300 | 1854 | 1549 | 1651 | 3235 | ||

| 1500 | 1640 | 14500 | 2150 | 1570 | 2210 | 5835 | ||

| 2000 | 2160 | 20645 | 2220 | 1600 | 2380 | 6430 | ||

| 2500 | 2680 | 23786 | 2330 | 1650 | 3070 | 8865 | ||

| 3000 | 3300 | 30300 | 2460 | 1850 | 3260 | 11300 | ||

| 3735 | 4125 | 37875 | 2680 | 2060 | 4080 | 14400 | ||

Applicable Standards

IEEE

Std

C

57.12.00

–

Standard

for

Standard

General

Requirements

for

Liquid-Immersed

Distribution,

Power,

and

Regulating

Transformers.

IEEE

Std

C

57.12.28

–

Pad-Mounted

Equipment

-

Enclosure

Integrity.

IEEE

Std

C

57.12.34

–

Standard

Requirements

for

Pad-Mounted,

Compartmental-Type,

Self-Cooled,

Three-Phase

Distribution

Transformers

IEEE

Std

C

57.12.90–

Standard

Test

Code

for

Liquid-Immersed

Distribution,

Power,

and

Regulating

Transformers

and

IEEE

Guide

for

Short-Circuit

Testing

of

Distribution

and

Power

Transformers.

IEEE

Std

C

57.12.91

–

Guide

for

Loading

Mineral-Oil-Immersed

Transformers.

Production process

UL /cUL Certification

FAQ

1. Q: Can I have a sample order?

A: Yes, we welcome sample order to test and check quality.

2. Q: What is the lead time?

A: Mass production time 15-25 days.

3. Q: How long is the warranty?

A: 24 monthes from B/L. If there are any accessory problems,just provide the photos of damaged accessory,then we will provide free service. According to the number of products,we will provide easily damaged accessories for free. we also can provide technical support if you need.

4. Q: Is OEM/ODM available?

A: Yes,it is! We are manufacturer with our own R&D team, we can customize products according to customer's drawing or requirements.

Customized services:

a. Customized color and special function.

b. Customized box.

c. Print customer's logo.

d. Your other ideas about product, we can help you design and put them into production. The above customized services must be confirmed before production.

5. Q: How to control the products quality?

A: Our company owns the core technology ,all kinds of products hold CE certificate. We have professional engineers. Workers are strictly required to make products according to the drawings. Each process has technical instructors.The QC supervisors will regularly inspect the production. We will do products performance tests during production, and comprehensive quality tests when the products is completed.