| Price | Negotiable |

| MOQ | 100 Pieces |

| Delivery Time | For the size we have in stock,5 working days |

| Brand | QIANPU |

| Place of Origin | Anping of China |

| Certification | ISO |

| Packaging Details | Inside with plastic film, outside with carton box or wooden box, and then in a pallet. It's also available as your requirements. |

| Supply Ability | 200000 piece per month |

| Fuilter Rating | 1 micron to 300 micron | Place of Origin | Anping of China |

| Packaging Details | Inside with plastic film, outside with carton box or wooden box, and then in a pallet. It's also available as your requirements. | Product Name | Sintered Mesh with Perforated Metal |

| Weave Types | Plain Weave, Twill Weave, Duch Weave | Material | Stainless Steel Wire |

| Dutch Mesh Count | 325 x 2300 | Supply Ability | 200000 piece per month |

| Certification | ISO | Brand Name | QIANPU |

| Type | Weave Wire Mesh, Filter disc | Delivery Time | For the size we have in stock,5 working days |

| Minimum Order Quantity | 100 Pieces | Standard Size | 500 mm × 1000 mm, 600 mm × 1200 mm, 1000 mm × 1000 mm, 1200 mm × 1200 mm, 1180 mm × 1450 mm, 1200 mm × 1500 mm, |

| Mesh Count | 635 x 635 | Features | outstanding permeability and great strength |

| Punched Metal | Round, Diamond, etc |

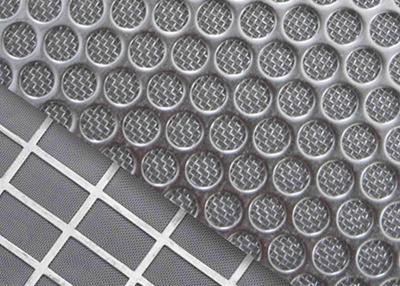

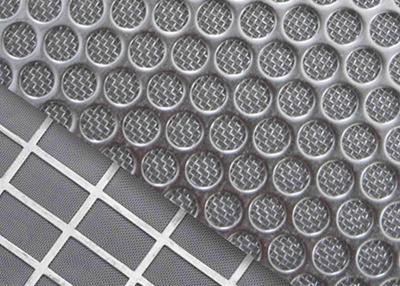

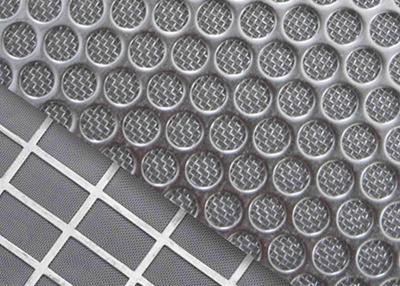

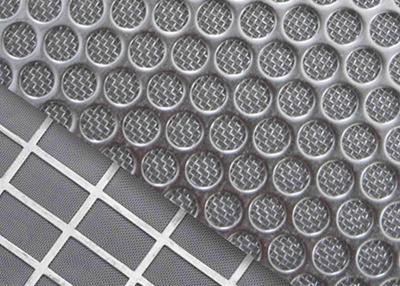

Sintered mesh with perforated metal, also named perforated metal sintered wire mesh, is a kind of compound sintered mesh which fits precise filtration and the need to protect the filtration layer. It is produced by combing several layers of stainless steel woven wire meshes and then sintering them to one piece of perforated metal. The support of a perforated metal sheet makes the sintered mesh extremely resistant to pressure and offers high compressive and mechanical strength. The perforated metal laminate varies in thickness and the opening of the hole size, the woven wire mesh can be one or more layers, which all fit the need of real application. Perforated metal sintered wire mesh can also be processed into different shapes, like chip, conical, cylinders, disc and tube. Owing to its outstanding permeability and great strength, it plays an important role in diverse filtration applications such as gas and liquid separation, recycle of solid particles, etc.

The

standard

materials

are

SUS316(AISI316),SUS316L(AISI316L)

This

type

of

mesh

is

sintered

together

by

punching

plate

and

muti-layer

stainless

steel

wire

mesh.

Duo

to

the

support

of

punching

plate,

it

has

higher

compressive

and

mechanical

strength.

Mainly

used

in

food,

beverage,

water

treatment,

dust

removing,

pharmaceutical,

polymer,

etc

|

Model |

Structure |

Filter Rating(μ) |

Thinkness(mm) |

Weight(kg/m²) |

Porosity(%) |

|

PL-2.0T |

30+filter layer+30+Φ4x5Px1.0t |

2-200 |

2.0 |

6.7 |

57 |

|

PL-2.5T |

30+filter layer+30+Φ5x7Px1.5t |

2-200 |

2.5 |

9.8 |

50 |

|

PL-1.5T |

60+filter layer+30+Φ1.5x3Px1.0t |

2-100 |

1.5 |

8.2 |

30 |

|

PL-3.0T |

60+filter layer+60+20+Φ6x8Px2.0t |

2-200 |

3.0 |

11.8 |

50 |

|

PL-4.0T |

20+ filter layer+20+10+Φ8x10Px2.5t |

2-200 |

4.0 |

14.2 |

55 |

|

PL-4.3T |

20+ filter layer+20+10+Φ10x13Px3.0t |

5-200 |

4.3 |

16.9 |

50 |

High

mechanical

strength

makes

the

sintered

mesh

full

of

rigidity.

High

corrosion

and

abrasion

resistance

prolongs

its

service

life.

Easy

for

cutting,

bending,

welding

or

other

processes.

Precise

filtration

for

great

permeability.

Continuous

operating

temperature

ranges

from

-20

°C

to

600

°C.

Easy

to

be

back

washed.

Performance and advantages of steel fiber mesh:

1.High dirt holding capacity,high filtering accuracy,longer on stream lifel.

2.Corrosion resistance of nitric acid,alkali, and organic solvent proof. It can be used for a long period of service in the temperature of 600℃.

3.High porosity and excellent permeability which results in low pressure drop and large flow.

4.Pleatable,provide a large filter area, and can be welded and machined.

5.Cleanable,can be used many times.

Perforated metal sintered filter is widely used in many industries where fine particles need to be filtered under extremely high pressure environment. These industries involves chemistry, pharmacy, petroleum, aviation, food, metallurgy, etc.

Anping tenglu metal wire mesh co.,ltd,is a manufacture and exporter of stainless steel wire mesh product.

We are located in wire mesh industrial base Anping city,Hebei province in China.

Our product range is as below,

Stainless steel woven wire mesh

Welded wire mesh

Crimped wire mesh

Hexagonal wire mesh

Knitted wire mesh

Wire mesh filter

Window screen

It have been 15 years that we manufacture and export wire mesh product,our professional responsible attitude and our strictly management technique ensure us standing in the leading position of wire mesh industry.We welcome your enquiry.

Sintered

Mesh

Plain

Weave

Sintered

Mesh

Dutch

Woven

Sintered

Wire

Mesh

Perforated

Metal

Sintered

Wire

Mesh

Brass

Pneumatic

Mufflers

/

Sintered

Silencer

Stainless

Steel

Pneumatic

Mufflers

/

Sintered

Silencer

Sintered

Filter

Elements

Sintered

Mesh

Filter

Cartridges

Sintered

Metal

Filter

Disc

Sintered

Wire

Mesh

Laminates

Sintered

Tube

Filter

Stainless

Steel

Sintered

Fiber

Felt

Iron-Chromium-Aluminum

Fiber

Felt

Sintered

Stainless

Steel

Powder

Filter

Element

Titanium

Powder

Sintered

Filter

Sintered

Copper

Powder

Filter

Elements

Five-Layer

Sintered

Mesh

Sintered

Mesh

Laminate

Sintered

Mesh

With

Perforated

Metal

Sintered

Metal

Filter

Cartridge

Pleated

Sintered

Mesh

Filter

Sintered

Mesh

Cone

Filter

Sintered

Metal

Fiber

Felt