| Price | Negotiable |

| MOQ | 20KM |

| Delivery Time | 7 days |

| Brand | YUANTONG |

| Place of Origin | China |

| Certification | ROSH ,TLC, CCC, ISO |

| Model Number | GYDXTW34 |

| Packaging Details | Wooden Drum |

| Payment Terms | L/C, D/P, T/T, Western Union |

| Supply Ability | 500km per week |

| Place of Origin | China | Cable Sheath | PE sheath |

| Packaging Details | Wooden Drum | Product Name | 12 Core Anti-Termite Metallic strength member Fiber Ribbon Central Tube Steel-PE Sheath GYDXTW34 |

| Loose Tube | PBT | Model Number | GYDXTW34 |

| Fiber Count | 12 Core | Fiber Type | G652D |

| Cable Use | Direct burial | Supply Ability | 500km per week |

| Certification | ROSH ,TLC, CCC, ISO | Brand Name | YUANTONG |

| Payment Terms | L/C, D/P, T/T, Western Union | Cable Color | Black |

| Price | Negotiable | Delivery Time | 7 days |

| Minimum Order Quantity | 20KM | Strength Member | metallic strength member |

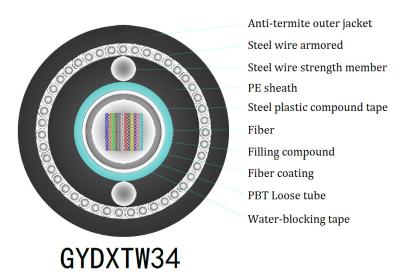

12 Core Anti-Termite Metallic strength member Fiber Ribbon Central Tube Steel-PE Sheath GYDXTW34

Description:

GYDXTW34

is

suitable

for

Direct

burial,Underwater-laying

application.

It

has

two

parallel

steel

wire

in

the

outer

jacket.

The

fiber

ribbon

structure

allows

fiber

concentrated

in

a

samll

diameter,

easy

to

connect

,

saving

much

cost.

| Model | Description | Applications |

| GYDXTW34 | Metallic strength member,Fiber ribbon central tube,Filling type,Entrained steel wire,Steel-PE sheath,Single steel wire armored,,PE outer jacket,Anti-termite | Direct burial,Underwater-laying,Anti-termite |

| Tensile Strength (N) | Crush Resistance (N/100mm) |

Bned

Radius (mm) |

Working Temperature(℃) | Max. attenuation (dB/km) | |||||

| Long term | short term | Long term | short term | Static(D) | Dynamic (D) | Min.TA | Max.TB | 1310μm | 1550μm |

| 4000 | 10000 | 3000 | 5000 | 12.5 D | 25 D | -40℃ | +60℃ | ≤0.36 | ≤0.22 |

| Category | Description | Specifications | |

| G.652D | |||

| Optical Specifications | Attenuation | @1310nm | ≤0.36dB/km |

| @1550nm | ≤0.22dB/km | ||

| Attenuation discontinuity | ≤0.05 dB | ||

| Attenuation vs. Wavelength | @1285~1330nm | ≤0.05 dB/km | |

| @1525~1575nm | ≤0.05 dB/km | ||

| Zero Dispersion Wavelength | 1300~1324nm | ||

| Zero Dispersion Slope | ≤0.092ps/(nm2.km) | ||

| Dispersion | @1310nm | ≤3.5 ps/nm.km | |

| @1550nm | ≤18 ps/nm.km | ||

| Polarization Mode Dispersion(PMD) | ≤0.2ps/km1/2 | ||

| Cable Cutoff Wavelength(λcc) | ≤1260nm | ||

| Effective Group Index of Refraction | @1310nm | 1.4675 | |

| @1550nm | 1.4681 | ||

| Macro bend loss (30mm radius,100turns) 1625nm | ≤0.1 dB | ||

|

Geometric Specifications |

Mode Field Diameter | @1310nm | 9.2±0.6μm |

| @1550nm | 10.4±0.8μm | ||

| Cladding Diameter | 125±1μm | ||

| Cladding Non-Circularity | ≤1.0% | ||

| Coating Diameter | 245±7μm | ||

| Coating/Cladding Concentricity Error | ≤8μm | ||

| Core/Cladding Concentricity Error | ≤0.8μm | ||

|

Mechanical Specifications |

Proof Test level | ≥1.0% | |

| Fiber Curl Radius | ≥4.0m | ||

| Peak Coating Strip Force | 1.3~8.9N | ||