Hello,

please

don't

feel

strange

when

you

see

words

like

mine.

I

am

the

boss

of

this

mask

machine

enterprise.

I

have

been

doing

research

and

development

of

machinery

and

equipment

for

ten

years.

I

didn't

expect

the

sudden

outbreak

of

the

epidemic

this

year

to

transform

our

company

into

mask

machines.

I

have

always

been

very

strict

in

doing

things,

and

so

has

the

mask

machine

designed

by

our

company.

I

have

participated

in

the

control

of

our

machines

from

design

to

purchase

related

raw

materials.

Every

detail

of

the

machine

is

done

with

great

precision.

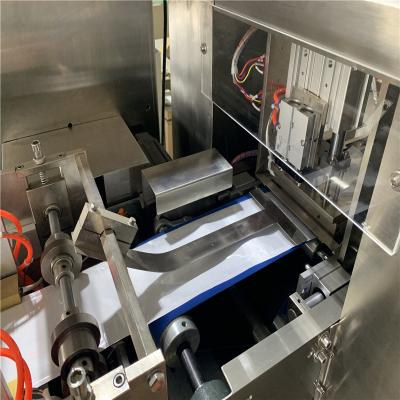

The

machine

runs

stably

and

is

easy

to

operate.

There

is

a

Korean

interface.

At

present,

plane

mask

machines

have

been

made

for

more

than

1,000

years

this

year,

and

KF94

South

Korea

has

exported

more

than

200

units.

The

factory

still

has

100

semi-finished

products

in

stock.

Can

be

assembled,

installed,

debugged

and

shipped

at

any

time.

The

fastest

delivery

speed

can

be

one

to

two

days.

Special

custom-made

mask

appearance,

10

days

delivery.

KN95

has

produced

a

total

of

300

units,

and

there

are

still

80

units

in

stock,

which

are

on

sale

at

a

special

price.

70-80

pcs

per

minute.

Details

can

be

found

on

the

website

about

the

introduction

of

relevant

machines.

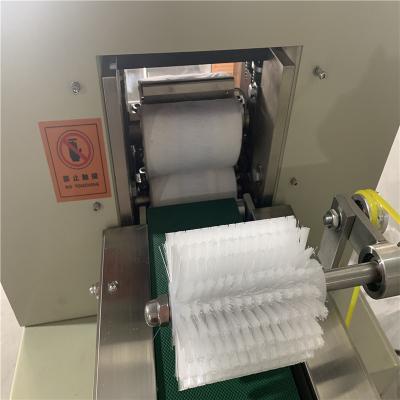

The

KF94

packaging

machine

we

made

was

followed

by

the

machines

bought

from

South

Korea

and

improved

many

shortcomings

of

the

past

machines.

We

are

rigorous

and

professional

in

the

mask

machine

industry.

I

would

like

to

make

a

special

mention

of

South

Korea's

door-to-door

installation

service.

It

usually

takes

10-15

days

from

the

time

you

place

an

order

to

the

time

when

the

goods

arrive.

Shipping

from

Qingdao

port,

transportation

time:

3-5

days.

After

delivery,

we

will

arrange

the

time

for

after-sales

personnel

to

install

in

advance

and

train

your

employees

how

to

operate

one-stop

service.

After-sales

warranty

period

of

one

year,

if

you

have

any

questions,

you

can

contact

the

company's

after-sales

customer

service

in

time.

The

company

will

arrange

personnel

to

carry

out

on-site

maintenance

in

the

first

place.

Originated

from

the

Internet,

for

reference

only

In

the

packaging

machine

industry,

the

bag-type

packaging

machine

in

my

country

has

been

particularly

popular

in

recent

years

because

it

saves

labor.

The

labor

cost

saved

by

a

machine

in

a

year

saves

the

cost

of

the

machine.

Japan's

Sanyo

used

to

make

bag

packaging

machines

early,

but

imported

more

than

one

million

machines,

and

the

packaging

speed

is

also

very

slow,

which

is

not

particularly

in

line

with

the

status

quo

of

most

of

our

domestic

enterprises.

In

our

country,

there

was

a

company

in

Qingdao

that

imitated

the

drawings

of

Sanyo

in

Japan

and

started

doing

it

for

nearly

ten

years,

and

the

performance

was

average.

Later,

packaging

companies

in

Zhejiang

began

to

make

this

kind

of

bag-feeding

packaging

machine.

Everyone

should

know

that

the

bag

packaging

machine

has

multiple

functions

such

as

metering,

sealing,

and

vacuuming.

Zhejiang

companies

do

most

of

the

bag

packaging

machines

with

sealing

functions,

but

if

a

machine

is

debugged

for

a

month,

both

the

manufacturer

and

the

user

will

feel

tired.

Shandong

Zhucheng

is

mostly

doing

vacuum

functions,

and

has

also

seen

the

market

for

bag

packaging

machines,

so

it

has

also

joined

the

competition.

In

this

industry,

there

has

basically

been

a

state

of

development

of

enterprises

with

different

advantages

in

the

north

and

south

bag

packaging

machines.

This

machine

replaces

manual

packaging.

It

can

pack

liquids

and

pastes

such

as

shrimp

slips,

solid

particles

such

as

various

nut

preserves,

and

lumps

such

as

trotters

and

duck

wings.

It

has

realized

packaging

automation

for

large

and

medium-sized

enterprises.

As

long

as

a

staff

member

puts

hundreds

of

finished

bags

in

the

bag

taking

part

of

the

equipment

at

a

time,

the

mechanical

claws

of

the

equipment

will

automatically

take

the

bag,

print

the

date,

open

the

bag,

and

signal

the

metering

device.

Measure

and

blank,

seal

and

output.

Main

functions

and

features:

1.

This

machine

replaces

traditional

manual

packaging,

realizes

product

packaging

production

automation,

improves

production

efficiency,

and

greatly

reduces

product

costs.

The

entire

set

of

equipment

can

be

completed

by

one

person

alone,

which

greatly

reduces

labor

costs.

2.

The

machine

is

equipped

with

an

automatic

monitoring

system

device,

which

can

detect

air

pressure,

temperature

controller

failure,

and

whether

the

opening

of

the

packaging

bag

is

opened

to

determine

the

state

of

the

machine;

it

can

control

whether

the

coding

device,

filling

device,

and

heat-sealing

device

are

in

action,

thereby

Avoid

wasting

packaging

materials

and

raw

materials.

3.

It

can

meet

a

variety

of

functions

and

can

be

used

in

conjunction

with

other

various

equipment.

4.

Composed

of

two

separate

rotating

bodies

(filling

system

and

vacuum

system),

the

filling

system

is

intermittent

rotating

operation,

and

the

vacuum

system

is

continuous

rotating

motion.

5.

Quickly

change

the

specifications

of

the

packaging

bag,

and

the

width

of

the

automatic

bag

feeding

device

can

be

automatically

adjusted

at

one

time.

6.

Meet

the

hygienic

standards

of

food

processing

machinery.

The

parts

on

the

machine

that

are

in

contact

with

materials

or

packaging

bags

are

made

of

stainless

steel

or

other

materials

that

meet

food

hygiene

requirements

to

ensure

food

hygiene.

7.

It

is

easy

to

clean

and

can

be

cleaned

in

the

vacuum

chamber.

8.

Low

packaging

material

loss.

This

machine

uses

prefabricated

packaging

bags

with

good

sealing

quality,

which

improves

the

product

quality.

The

bag

can

be

recycled

without

cutting

or

sealing.

9.

Adopt

advanced

PLC

plus

POD

electrical

control

system,

friendly

man-machine

interface

and

convenient

operation.

The

angle

and

time

of

pneumatic

components

can

be

automatically

adjusted.

At

present,

each

manufacturer

of

the

bag

packaging

machine

focuses

on

different

industries,

such

as

corn,

zongzi,

pickles,

liquids,

etc.

Each

manufacturer

also

focuses

on

several

industries,

so

when

choosing

a

bag

packaging

machine,

users

need

to

investigate

more

And

understand.