Hello,

please

don't

feel

strange

when

you

see

words

like

mine.

I

am

the

boss

of

this

mask

machine

enterprise.

I

have

been

doing

research

and

development

of

machinery

and

equipment

for

ten

years.

I

didn't

expect

the

sudden

outbreak

of

the

epidemic

this

year

to

transform

our

company

into

mask

machines.

I

have

always

been

very

strict

in

doing

things,

and

so

has

the

mask

machine

designed

by

our

company.

I

have

participated

in

the

control

of

our

machines

from

design

to

purchase

related

raw

materials.

Every

detail

of

the

machine

is

done

with

great

precision.

The

machine

runs

stably

and

is

easy

to

operate.

There

is

a

Korean

interface.

At

present,

plane

mask

machines

have

been

made

for

more

than

1,000

years

this

year,

and

KF94

South

Korea

has

exported

more

than

200

units.

The

factory

still

has

100

semi-finished

products

in

stock.

Can

be

assembled,

installed,

debugged

and

shipped

at

any

time.

The

fastest

delivery

speed

can

be

one

to

two

days.

Special

custom-made

mask

appearance,

10

days

delivery.

KN95

has

produced

a

total

of

300

units,

and

there

are

still

80

units

in

stock,

which

are

on

sale

at

a

special

price.

70-80

pcs

per

minute.

Details

can

be

found

on

the

website

about

the

introduction

of

relevant

machines.

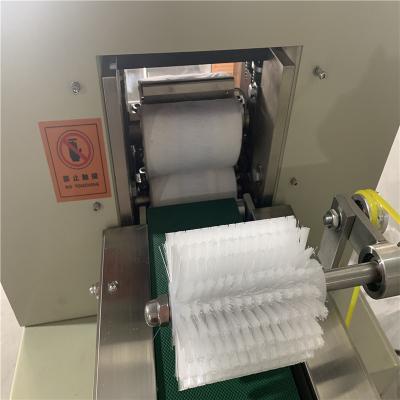

The

KF94

packaging

machine

we

made

was

followed

by

the

machines

bought

from

South

Korea

and

improved

many

shortcomings

of

the

past

machines.

We

are

rigorous

and

professional

in

the

mask

machine

industry.

I

would

like

to

make

a

special

mention

of

South

Korea's

door-to-door

installation

service.

It

usually

takes

10-15

days

from

the

time

you

place

an

order

to

the

time

when

the

goods

arrive.

Shipping

from

Qingdao

port,

transportation

time:

3-5

days.

After

delivery,

we

will

arrange

the

time

for

after-sales

personnel

to

install

in

advance

and

train

your

employees

how

to

operate

one-stop

service.

After-sales

warranty

period

of

one

year,

if

you

have

any

questions,

you

can

contact

the

company's

after-sales

customer

service

in

time.

The

company

will

arrange

personnel

to

carry

out

on-site

maintenance

in

the

first

place.

Originated

from

the

Internet,

for

reference

only

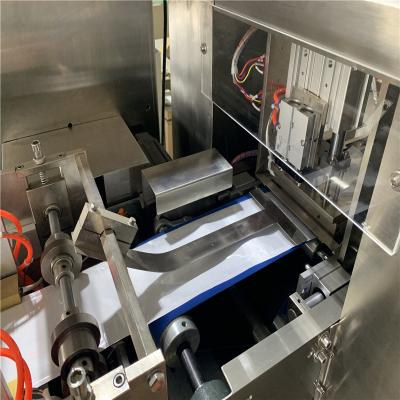

The

machine

adopts

imported

PLC

control,

man-machine

interface

and

pneumatic

components

to

realize

packaging

automation.

Operators

only

need

to

put

hundreds

of

packages

into

the

recycling

department

of

the

equipment

at

a

time

to

provide

the

latest

products

and

best

services

for

food,

chemicals,

medicines,

seeds,

etc.

Therefore,

it

is

very

important

to

choose

a

packaging

machine

suitable

for

your

own

product

packaging.

Now

introduce

the

four

optional

principles

on

the

packaging

machine.

To

bag

packaging

machine

1.

It

meets

the

requirements

of

food

packaging

technology

and

has

good

adaptability

to

food

material

selection

and

container.

It

requires

advanced

technology,

stable

and

reliable

work,

low

energy

consumption,

easy

use

and

maintenance

to

ensure

packaging

quality

and

packaging

production

efficiency.

2.

Pay

attention

to

the

generality

of

machinery,

and

can

adapt

to

the

packaging

needs

of

various

foods.

It

meets

food

hygiene

requirements,

is

clean

and

convenient,

and

does

not

pollute

food.

3.

There

are

reasonable

and

reliable

control

devices

for

the

temperature,

pressure,

time,

measurement,

speed,

etc.

of

food

packaging,

and

automatic

control

methods

are

adopted

as

much

as

possible

to

produce

a

single

product

for

a

long

time,

and

select

special

machines.

Automatic

bag-feeding

packaging

machine

4.

Multi-variety,

same

type,

multi-specification

products,

multi-purpose

automatic

bagging

multi-purpose

packaging

machine,

which

can

complete

multiple

packaging

tasks

at

one

time,

improve

productivity,

save

labor,

and

reduce

space

occupation.

Improve

the

working

conditions

of

workers

and

reduce

labor

intensity.