Hello,

please

don't

feel

strange

when

you

see

words

like

mine.

I

am

the

boss

of

this

mask

machine

enterprise.

I

have

been

doing

research

and

development

of

machinery

and

equipment

for

ten

years.

I

didn't

expect

the

sudden

outbreak

of

the

epidemic

this

year

to

transform

our

company

into

mask

machines.

I

have

always

been

very

strict

in

doing

things,

and

so

has

the

mask

machine

designed

by

our

company.

I

have

participated

in

the

control

of

our

machines

from

design

to

purchase

related

raw

materials.

Every

detail

of

the

machine

is

done

with

great

precision.

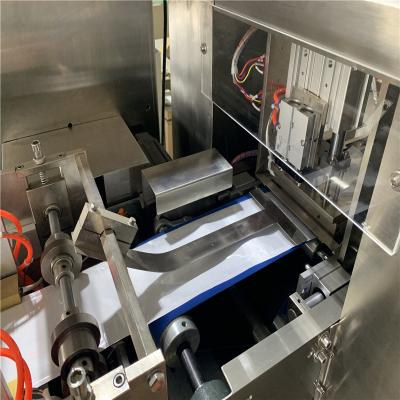

The

machine

runs

stably

and

is

easy

to

operate.

There

is

a

Korean

interface.

At

present,

plane

mask

machines

have

been

made

for

more

than

1,000

years

this

year,

and

KF94

South

Korea

has

exported

more

than

200

units.

The

factory

still

has

100

semi-finished

products

in

stock.

Can

be

assembled,

installed,

debugged

and

shipped

at

any

time.

The

fastest

delivery

speed

can

be

one

to

two

days.

Special

custom-made

mask

appearance,

10

days

delivery.

KN95

has

produced

a

total

of

300

units,

and

there

are

still

80

units

in

stock,

which

are

on

sale

at

a

special

price.

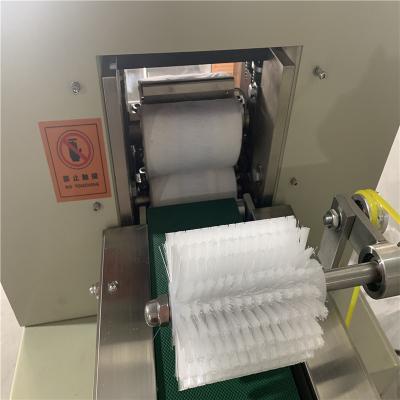

70-80

pcs

per

minute.

Details

can

be

found

on

the

website

about

the

introduction

of

relevant

machines.

The

KF94

packaging

machine

we

made

was

followed

by

the

machines

bought

from

South

Korea

and

improved

many

shortcomings

of

the

past

machines.

We

are

rigorous

and

professional

in

the

mask

machine

industry.

I

would

like

to

make

a

special

mention

of

South

Korea's

door-to-door

installation

service.

It

usually

takes

10-15

days

from

the

time

you

place

an

order

to

the

time

when

the

goods

arrive.

Shipping

from

Qingdao

port,

transportation

time:

3-5

days.

After

delivery,

we

will

arrange

the

time

for

after-sales

personnel

to

install

in

advance

and

train

your

employees

how

to

operate

one-stop

service.

After-sales

warranty

period

of

one

year,

if

you

have

any

questions,

you

can

contact

the

company's

after-sales

customer

service

in

time.

The

company

will

arrange

personnel

to

carry

out

on-site

maintenance

in

the

first

place.

Originated

from

the

Internet,

for

reference

only

With

the

continuous

upgrading

of

automation

equipment

in

all

walks

of

life,

in

order

to

continuously

improve

product

quality

and

influence!

In

the

mechanical

packaging

industry,

constantly

upgrading

equipment

with

a

simple

structure

and

a

higher

degree

of

automation.

The

bag

packaging

machine

adopts

a

hollow

rotating

platform

for

multiple

circumferential

positioning.

In

general

automated

packaging

machinery

and

equipment,

like

multi-station

automatic

bag-feeding

packaging

machines,

the

multi-station

mechanism

adopts

a

belt

pulley

+

a

part

of

the

mechanism

with

a

motor.

The

space

structure

of

the

mechanism

is

cumbersome,

and

the

status

of

each

part

needs

to

be

debugged.

The

hollow

rotating

platform

is

directly

connected

to

the

motor,

which

saves

space

and

has

a

simple

structure.

The

working

table

and

mechanical

arm

of

the

device

can

be

directly

installed

on

the

hollow

rotating

platform

turntable.

Compared

with

the

use

of

belt

pulleys

and

other

mechanical

parts,

it

can

reduce

the

man-hours

and

work

of

mechanism

design,

parts

deployment,

etc.

cost

In

some

equipment,

a

cam

divider

is

used

to

divide

into

multiple

stations,

but

the

cam

divider

can

only

be

divided

into

fixed

equal

stations

and

can

only

rotate

in

one

direction.

And

our

hollow

rotating

platform,

similar

to

the

cam

divider,

does

not

need

to

add

an

additional

support

system,

the

load

can

be

directly

placed

on

the

hollow

rotating

platform

disk

drive,

it

can

be

positioned

at

any

angle

of

360

degrees,

divided

into

any

station,

frequent

forward

and

reverse

positioning

,

Wait

for

the

characteristics

that

these

cam

dividers

can’t

meet,

and

the

large-aperture

hollow

structure

makes

your

wiring

more

convenient,

more

application

scenarios,

and

more

convenient

to

use.

At

the

same

time,

our

accuracy

can

be

comparable

to

DD

motors,

but

the

price

is

affordable.

Balance

with

DD

motor.

Because

of

the

above

characteristics,

it

is

more

and

more

widely

used

in

automated

packaging

equipment!