Hello,

please

don't

feel

strange

when

you

see

words

like

mine.

I

am

the

boss

of

this

mask

machine

enterprise.

I

have

been

doing

research

and

development

of

machinery

and

equipment

for

ten

years.

I

didn't

expect

the

sudden

outbreak

of

the

epidemic

this

year

to

transform

our

company

into

mask

machines.

I

have

always

been

very

strict

in

doing

things,

and

so

has

the

mask

machine

designed

by

our

company.

I

have

participated

in

the

control

of

our

machines

from

design

to

purchase

related

raw

materials.

Every

detail

of

the

machine

is

done

with

great

precision.

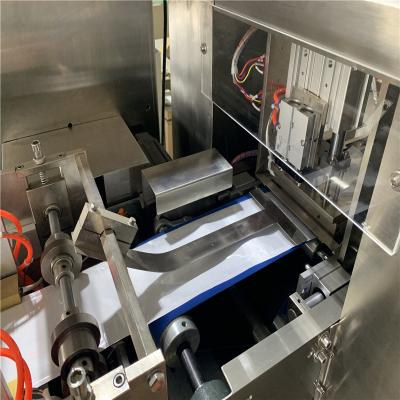

The

machine

runs

stably

and

is

easy

to

operate.

There

is

a

Korean

interface.

At

present,

plane

mask

machines

have

been

made

for

more

than

1,000

years

this

year,

and

KF94

South

Korea

has

exported

more

than

200

units.

The

factory

still

has

100

semi-finished

products

in

stock.

Can

be

assembled,

installed,

debugged

and

shipped

at

any

time.

The

fastest

delivery

speed

can

be

one

to

two

days.

Special

custom-made

mask

appearance,

10

days

delivery.

KN95

has

produced

a

total

of

300

units,

and

there

are

still

80

units

in

stock,

which

are

on

sale

at

a

special

price.

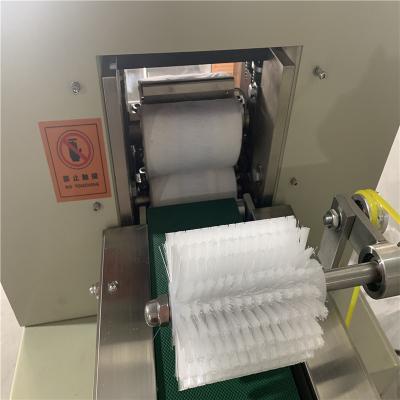

70-80

pcs

per

minute.

Details

can

be

found

on

the

website

about

the

introduction

of

relevant

machines.

The

KF94

packaging

machine

we

made

was

followed

by

the

machines

bought

from

South

Korea

and

improved

many

shortcomings

of

the

past

machines.

We

are

rigorous

and

professional

in

the

mask

machine

industry.

I

would

like

to

make

a

special

mention

of

South

Korea's

door-to-door

installation

service.

It

usually

takes

10-15

days

from

the

time

you

place

an

order

to

the

time

when

the

goods

arrive.

Shipping

from

Qingdao

port,

transportation

time:

3-5

days.

After

delivery,

we

will

arrange

the

time

for

after-sales

personnel

to

install

in

advance

and

train

your

employees

how

to

operate

one-stop

service.

After-sales

warranty

period

of

one

year,

if

you

have

any

questions,

you

can

contact

the

company's

after-sales

customer

service

in

time.

The

company

will

arrange

personnel

to

carry

out

on-site

maintenance

in

the

first

place.

Originated

from

the

Internet,

for

reference

only

Dongguan

automatic

non-oil

guide

sleeve

packaging

machine

manufacturer,

bag

packaging

machine

factory

2myqasm

Jiesheng

packaging

machine.

When

buying

a

new

packaging

machine,

the

shrinking

machine

and

sealing

and

cutting

machine

should

be

carried

out

in

the

above

order.

There

are

L-type

semi-automatic

heat

shrinking

machine

and

cuff-type

sealing

and

cutting

heat

shrinking

machine.

The

shrinking

machine

is

usually

a

heat

shrinkable

film

packaging

machine,

and

there

are

many

types

of

subdivisions.

In

fact,

the

sealing

and

cutting

shrinking

machine

is

also

called

the

film

sealing

and

cutting

shrinking

machine.

It

consists

of

two

parts:

sealing

and

cutting

shrinking

machine

and

shrinking

machine.

As

the

name

suggests,

the

film

sealing

and

cutting

shrinking

machine

has

two

functions,

one

is

the

sealing

and

cutting

of

the

film,

and

the

other

is

the

shrinking.

The

film

sealing

and

cutting

machine

uses

a

machine

to

cover

the

objects,

and

then

there

is

a

cutter

behind

the

film

making

machine

for

sealing

and

cutting.

The

situation

related

to

this

is

that

the

packaging

machinery

provides

users

with

similar

packaging

machinery,

but

the

users

use

such

packaging

machinery

as

specialized

packaging

machinery.

There

are

several

types

of

tube

filling

and

sealing

machines,

including

a

combination

of

a

semi-automatic

sealing

machine

and

a

small

paste

filling

machine,

and

an

ultrasonic

sealing

machine,

but

this

type

of

automation

is

too

low

and

the

sealing

part

is

slightly

flawed.

,

So

a

more

regular

tube

packaging

needs

a

turntable

type

There

is

a

temperature

on

the

cutter,

it

will

not

be

sealed

and

cut,

the

seal

will

be

neat

and

will

not

break.

The

product

is

sealed

and

cut

with

film.

After

that,

enter

the

shrinking

machine

to

pack

the

items.

The

sealing

and

cutting

machine

can

be

used

alone.

Many

items

only

need

to

be

sealed

and

cut

with

film

without

shrinking.

In

this

case,

you

only

need

to

buy

a

sealing

and

cutting

shrinking

machine.

.It

is

equipped

with

a

receiving

trough

to

prevent

materials

from

being

sprinkled

on

the

ground

and

troublesome

cleaning

during

debugging

or

when

it

is

out

of

order.

For

example,

for

boxes

and

other

items

that

require

film

sealing

and

cutting,

as

well

as

shrink

packaging

machines,

you

can

choose

a

shrinking

machine

for

sealing

and

cutting

film,

of

course,

you

can

also

choose

a

shrinking

machine,

but

the

premise

is

that

you

need

to

choose

a

shrinking

machine,

and

you

need

a

kind

of

artificial

sleeve

A

waste

of

labor,

but

theoretically

speaking,

it

will

not

affect

the

shrinkage

effect.

But

the

initial

application

range

is

very

small,

and

the

progress

is

very

slow.

The

summer

heat

is

at

two

or

three

o'clock

in

the

drowsy

afternoon.

Whether

it

is

work

or

school,

the

little

cute

people

want

to

come

to

a

pack

of

fast

dissolving

and

relieving

fatigue,

so

the

summer

bag

sales

are

It’s

very

high.

The

bags

in

the

supermarket

have

different

shapes,

long

and

square,

easy-to-tear

and

hanging

holes,

and

the

sealing

methods

are

different,

so

do

you

know

how

these

packaging

and

filling

come

from?

Of

What

are

the

classifications

of

balers:

①

Plastic

strap

balers.

A

strapping

machine

used

to

pack

medium

and

small

weight

cartons.

Commonly

used

plastic

tapes

are

mainly

polypropylene

tapes,

1

classified

by

strapping

materials.

There

are

also

nylon

belts,

polyester

belts

and

so

on.

②Fully

automatic

strapping

machine

for

steel

belts.

Steel

belts

are

used

as

binding

materials.

Because

of

the

high

strength

of

steel

belts,

they

are

mainly

used

for

heavy

and

large

packaging

cartons.

Due

to

the

wide

variety

of

packaging

products,

the

functions

of

the

automatic

packaging

machine

are

various,

and

the

complexity

of

the

equipment

and

process

operations

that

realize

its

functions

are

also

very

different.

Stepless

variable

frequency

speed

regulation

is

possible

③Portable

pneumatic

baler.

The

pneumatic

baler

is

suitable

for

metallurgy,

steel

and

building

materials

industries,

etc.,

suitable

for

all

kinds

of

PET

plastic

steel

belts.

The

tightening,

bonding

and

cutting

are

completed,

and

the

operation

is

simple.

2

Classified

according

to

structural

characteristics,

①Basic

automatic

baler.

It

is

suitable

for

balers

in

various

industries,

and

the

table

height

is

suitable

for

standing

operation.

The

manufacturer

of

automatic

non-oil

guide

sleeve

packaging

machine

in

Dongguan,

the

automatic

control

in

the

packaging

operation

of

the

bag

packaging

machine

factory

belongs

to

the

automatic

control

of

the

production

process,

and

the

automatic

control

of

the

continuous

automatic

packaging

machine

weighing

and

supplying

is

an

important

part

of

automation.

The

packaging

process

control

has

developed

with

the

development

of

automation.

For

families,

the

bag-making

filling

machine

has

many

advantages

over

manual

filling

and

is

more

suitable

for

use.

Choosing

a

bag-making

filling

machine

is

a

long-term

process.

Compared

with

labor,

the

purchase

of

bag-making

filling

machines

may

cost

a

little

more,

but

in

a

few

months

and

a

few

years,

it

will

far

exceed

manual

filling.

It

will

help

you

to

produce

more

products

and

open

up

the

market

for

sauce

filling.

The

amount

is

also

called

the

controlled

amount

or

the

adjusted

amount.

It

is

the

output

of

the

controlled

object.

It

is

the

target

of

automatic

control.

It

is

mostly

used

to

bundle

medium

and

small

packages,

such

as

cartons,

calcium

plastic

boxes,

books

and

magazines.

②Side-mounted

baler.

The

joint

part

of

the

strapping

is

carried

out

on

the

side

of

the

package,

and

the

table

top

is

lower.

It

is

suitable

for

bundling

of

large

or

polluting

packages.

If

anti-rust

treatment

is

applied,

aquatic

products

and

pickled

products

can

be

bundled;

if

dust-proof

measures

are

added,

packages

with

more

dust

can

be

bundled.

The

sealing

adopts

the

roller

method

to

make

the

appearance

of

the

product

tidy

and

the

sealing

is

firm

③Pressure

packer.

For

soft

and

elastic

products

such

as

leather,

paper

products,

knitted

cotton

fabrics,

etc.,

in

order

to

make

the

binding

tight,

it

must

be

compressed

before

binding.

There

are

two

types

of

pressurization:

pneumatic

and

hydraulic.

④Automatic

balers

for

opening

and

closing

tracks.

The

belt

track

frame

can

be

opened

and

closed

in

the

water

or

vertical

direction,

which

is

convenient

for

putting

in

various

cylindrical

or

ring-shaped

packages,

and

then

the

track

is

closed

and

tied.

Shacha

sauce

is

made

by

grinding

the

raw

materials,

and

then

adding

oil

and

other

condiments.

It

is

suitable

for

the

seasoning

when

cooking.

Because

of

its

strong

mellow

aroma,

it

is

deeply

loved

by

people.

The

shacha

sauce

on

the

market

is

generally

The

vacuum

state

of

the

glass

bottle

is

more

conducive

to

transportation

and

storage.

It

is

used

for

filling

Shacha

sauce

on

the

market.

Dongguan

automatic

non-lubricating

guide

sleeve

packaging

machine

manufacturer,

bag

packaging

machine

factory

intermittent

automatic

packaging

machine

weighing

and

supply

non-contact

detection

and

control

devices

used

in

detection

sensors

mainly

include

switches,

photoelectric

relays,

etc.,

which

can

be

quickly

disassembled,

Quick

assembly

structure

makes

cleaning

easier.