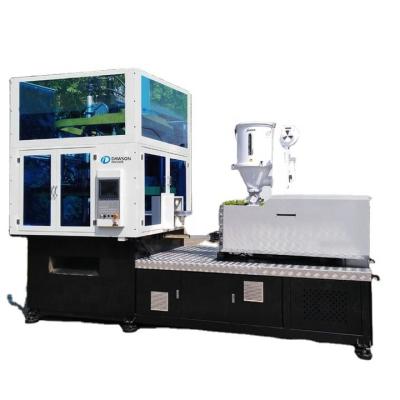

This

machine

has

three

stations,

injection

preform,

blowing

&

stretch

and

product

release.

The

raw

material

comes

from

the

hopper

to

the

injection

screw

to

inject

preform;

the

plate

rotates

preforms

to

blow/stretch

blow

station

with

themselves

heat,

without

any

reheating

for

blowing,then

the

product

will

rotate

to

release

station

and

drop

down,

It's

fully

automatically

cycle

rotation

working

mode,no

need

to

buy

bottle

preform,

no

waste,

high

degree

of

automation,

finished

products

smooth

and

beautiful.

Commonly

used

in

10-1000

ml

PET

cosmetic

bottle,

milk

bottle,

sports

water

bottle,

pharmaceutical

packaging,

PC

bottle,

red

wine

cup

and

LED

lampshade,

etc

|

Model

|

ISB

800-3

|

|

Injection

Part

|

|

Screw

Diameter

|

40mm

|

|

Screw

L/D

Ratio

|

20.5:1

|

|

Screw

Speed

|

0-190RPM

|

|

Theoretical

Injection

Capacity

|

238cm3

|

|

Injection

Pressure

|

174Mpa

|

|

Max.

Hydraulic

Pressure

|

140Kg/cm

|

|

The

Actual

Injection

Quantity(PS):

|

225g(ps)/8Oz

|

|

Screw

Stroke:

|

190Mm

|

|

Clamping

Part

|

|

Blow

Clamping

Force:

|

80Kn

|

|

Clamp

Tonnage:

|

400Kn

|

|

Wheel

Diameter:

|

800mm

|

|

Max.

Height

of

Bottle:

|

ISB:145/IB:140

|

|

Open

Vertical

Mode

Trip:

|

430mm

|

|

Others

|

|

Max.

Pump

Pressure:

|

16Mpa

|

|

Motor

Oil:

|

18.5Kw

|

|

Electric

Power:

|

12.2Kw

|

|

Oil

Tank:

|

400L

|

|

Overall

Dimension(L*W*H):

|

3.8m*1.45m*3.0m

|

|

Weight:

|

5000kg

|

1.

The

wheel

rotation

is

driven

by

electrical

servo

motor,

not

hydraulic.

2.

Full

automatic

controlling

system,

easy

operating.

3.

The

temperature

of

material

barrel

and

hot

runner

is

controlled

accurately

by

PIT.

4.

More

cost

is

saved

than

traditional

machine.

5.

Compact

structure;

less

space

needed.

6.

Injection:

Hot

runner

and

temperature

control

device

are

standard

configuration.

Only

change

mold

for

making

a

new

product;

Stretch

Blow:

Hydraulic

mold

clamping,

core

insert,

stretch

blow

and

bottom

molding

are

standard

configuration;

Product

Release:

Equipped

with

a

standard

ejector.

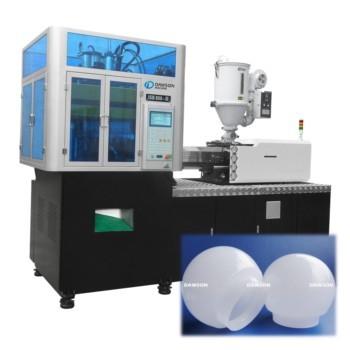

The

Injection

Stretch

Blow

Molding

Machine

process

includes

mould

injection,

stretch

blowing

and

off-molding,

all

these

steps

could

be

finished

in

one

step.

The

products

from

this

machine

don’t

have

flash,

sprue,

and

with

much

less

disfigurements.

It

presents

the

perfect

looking

mouth,

bottom

and

seam

as

well

as

better

transparency,

higher

rigidity.

ISBM

Injection

Stretch

Blow

Molding

Machine

products

are

thinner,

is

possible

to

help

you

save

50%

raw

material.

Besides

the

merit

mentioned

above,

this

machine

can

reach

higher

speed

so

as

to

achieve

higher

efficiency.

ISBM1100N-3

is

suitable

for

eye

dropper

bottles,

medicine

bottles,

cosmetic

bottles,

jars,

milk

bottles,

yogurt

bottles,

baby

bottles...etc.

With

the

increasing

requirement

of

high

quality

and

elegant

appearance

in

the

packing

field

of

food,

beverage,

and

cosmetic,

the

plastic

containers

made

by

the

old

style

extrusion

blowing

machine

cannot

meet

the

customer’s

demand

any

more.

However,

by

one

step

injection

stretch

blow

molding

machine,

from

the

raw

material

to

product

processed

are

all

by

one

step.The

whole

process

includes

preform

injection,stretch

blow

and

release.

No

need

trimmings,

No

runner

gate

material

(

no

scrap

),

but

perfect

neck,

bottom

and

line,

higher

transparent,

higher

rigid.

Stretch-blowing

molding

products

come

with

thinner

wall

and

save

more

material.

Company

Profile

DAWSON

MACHINERY

&

MOULD

GROUP

DAWSON

MACHINE

&

MOULD

GROUP

located

in

Zhangjiagang

city,

have

more

than

18

years'

experience

in

the

field

of

plastic

machinery,

blow

molding

machine,

injection

molding

machine,

PET

blow

molding

machine,

injection

blow

molding

machine,

injection

stretch

blow

molding

machine

during

the

past

18

years,

we

always

force

our

energy

into

new

areas

of

plastic

machinery,

plastic

packaging

machinery,

to

update

the

technology,

to

learn

advanced

experience,

to

confirm

new

theory

and

new

design,

we

are

forming

a

unique

competitive

advantage

of

our

owns.

The

machines

from

our

company

carry

good

quality

and

effective

after-sales

service,

upon

the

market,

customers

from

more

than

45

countries,

we

provide

complete

solution

for

your

plastic

industry

business,

as

well

as

all

sorts

of

technical

support

&

after-sale

services!

DAWSON

will

be

your

reliable

friend

in

China,

and

we

will

always

do

our

best

to

give

you

max

support!