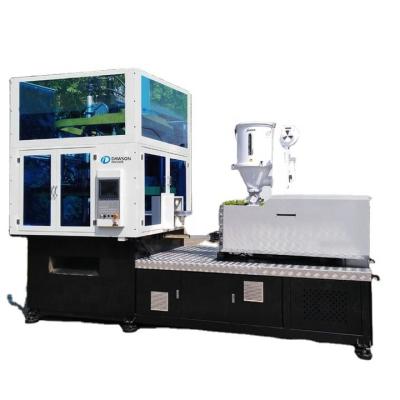

1.

The

wheel

rotation

is

driven

by

electrical

servo

motor,

not

hydraulic.

2.

Full

automatic

controlling

system,

easy

operating.

3.

The

temperature

of

material

barrel

and

hot

runner

is

controlled

accurately

by

PIT.

4.

More

cost

is

saved

than

traditional

machine.

5.

Compact

structure;

less

space

needed.

6.

Injection:

Hot

runner

and

temperature

control

device

are

standard

configuration.

Only

change

mold

for

making

a

new

product;

Stretch

Blow:

Hydraulic

mold

clamping,

core

insert,

stretch

blow

and

bottom

molding

are

standard

configuration;

Product

Release:

Equipped

with

a

standard

ejector.

With

the

increasing

requirement

of

high

quality

and

elegant

appearance

in

the

packing

field

of

food,

beverage,

and

cosmetic,

the

plastic

containers

made

by

the

old

style

extrusion

blowing

machine

cannot

meet

the

customer’s

demand

any

more.

However,

by

one

step

injection

stretch

blow

molding

machine,

from

the

raw

material

to

product

processed

are

all

by

one

step.The

whole

process

includes

preform

injection,stretch

blow

and

release.

No

need

trimmings,

No

runner

gate

material

(

no

scrap

),

but

perfect

neck,

bottom

and

line,

higher

transparent,

higher

rigid.

Stretch-blowing

molding

products

come

with

thinner

wall

and

save

more

material.

PET

water

bottle

stretch

blow

molding

machine

completes

a

high

speed

molding

without

preform

reheated.

With

the

heat

from

preform

injection

to

stretch

and

blow,

unnecessary

reheating

and

shorten

preform

cooling

time

to

save

energy.

Injection

Stretch

blow

molding

machine

optimizes

the

working

structure,

removes

molding

disadvantage

factor,

cuts

off

the

complicated

working

procedure

to

ensure

molding

more

reliable

and

increase

the

reject

rate.

One

Step

Injection

Stretch

blow

moulding

machine

decrease

the

convey

cost

and

avoid

the

second

contamination,

special

for

food

and

pharmaceutical

company.

For

example,

to

transit

the

19g

500ml

bottle,

if

the

1m³

trunk

used,

it

can

load

1024

bottles,

or

9280

preform,

but

if

buy

the

raw

material

that

can

produce

56421

bottles.

The

logistic

cost

of

material

comparing

with

transiting

bottles

can

be

reduced

by

98.2%;

Comparing

with

the

cost

of

transiting

preform,

the

cost

can

be

reduced

by

83.6%.

Company

Profile

DAWSON

MACHINERY

&

MOULD

GROUP

Our

customers

are

all

around

the

world.

Vietnam,

Australia,

Indonesia,

Malaysia,

Thailand,

Sri

Lanka,

Kazakhstan,

Russia,

UAE,

Saudi

Arabia,

Malta,

Romania,

Italy,

India,

Syria,

Ethiopia,

Egypt,

Sudan,

Tunisia,

Algeria,

Kenya,

Nigeria,

South

Africa,

Zimbabwe,

Mexico,

Guatemala,

Ecuador,

Colombia,

Venezuela,

Peru....

We

have

our

own

service

team

in

Saudi

Arabia,

Colombia,

Panama,

South

Africa

...