| Price | Negotiable |

| MOQ | 3 pieces |

| Delivery Time | 3-8 Working Days |

| Brand | AIRSUSTECH |

| Place of Origin | Guangzhou, China |

| Certification | ISO/TS16949, ISO9001 |

| Model Number | 1B8X4 |

| Packaging Details | Strong Carton Box or as Customers Requirement |

| Payment Terms | T/T, Western Union,Paypal or Others |

| Supply Ability | 1000pcs/week |

| Origin | China | Packaging Details | Strong Carton Box or as Customers Requirement |

| HS Code | 8708809000 | Port | Huangpu, China |

| Trademark | Neutral | Supply Ability | 1000pcs/week |

| Rubber Bellows | 1B 550 | Transport Package | Cartons |

| Minimum Order Quantity | 3 pieces | Plates | Crimped |

| Place of Origin | Guangzhou, China | Warranty | One Year |

| Position | Rear | Specification | 24*24*22 cm |

| Material | Rubber and Iron | Model Number | 1B8X4 |

| Certification | ISO/TS16949, ISO9001 | Brand Name | AIRSUSTECH |

| Payment Terms | T/T, Western Union,Paypal or Others | Pressure Ability | 0.2-0.8 M PA |

| Type | Suspension Spring | N.W. | 2.4 Kg |

| Model NO. | 1B8X4 | Delivery Time | 3-8 Working Days |

| OEM | Yes |

Product Description

Technical Data

AIRSUSTECH:1B8X4

OEM Original Equipment Manufacturer:FS 120-10 CI

AIR INLET 1/4 NPT:

Firestone : W01-358-7564

Goodyear:1B8-550

Contitech:FS120-10

Description

Assembly

Order

No.

Style 116 Two Ply Bellows

Blind

nuts,

1/4

NPT:W01-358-7564;W01

358

7564;W013587564

Blind

nuts,

3/4

NPT:W01-358-7561;W01

358

7561;W013587561

Countersunk

steel

bead

rings,19/4

bolts,

nuts,

washers:W01-358-7568;W01

358 7568;W013587568

Blind

nuts

with

installed

1/4 tank

valve W01-A72-7518;W01

A72 7518;W01A727518

Rubber

bellows

only:W01-358-0133;W01

358

0133;W013580133

Style 117 High Bellows

Blind

nuts,

1/4

NPT:W01-358-7600;W01

358 7600;W013587600

Blind

nuts,

3/4

NPT:W01-358-7602;W01

358

7602;W013587602

Countersunk

steel

bead

rings,Strength

13/4

bolts,

nuts,

washers:W01-358-7606;W01

358

7606;W013587606

|

Bearing load Power (kg) |

Inflation pressure | 0.2MPa | 0.3MPa | 0.4MPa | 0.5MPa | 0.6MPa | 0.7MPa | 0.8MPa |

0.7MPa Volume(dm³) |

|---|---|---|---|---|---|---|---|---|---|

| Installation height | |||||||||

| 55(mm) | 433 | 664 | 897 | 1131 | 1354 | 1585 | 1822 | 1.11 | |

| 78(mm) | 396 | 598 | 803 | 1015 | 1236 | 1441 | 1647 | 1.34 | |

| 101(mm) | 314 | 471 | 646 | 820 | 996 | 1175 | 1321 | 1.47 | |

| 124(mm) | 208 | 318 | 434 | 555 | 675 | 798 | 920 | 1.79 | |

| 130(mm) | 167 | 258 | 348 | 438 | 535 | 636 | 733 | 1.86 | |

| 147(mm) | 56 | 96 | 133 | 179 | 226 | 274 | 331 | 2.04 | |

| 149(mm) | 19 | 41 | 64 | 93 | 126 | 164 | 208 | 2.08 | |

| 155(mm) | 2 | 10 | 20 | 41 | 51 | 80 | 100 | 2.15 | |

| Stiffness and frequency at design height | Vertical stiffness(Kg/cm) | 132 | 170 | 182 | 203 | 230 | 268 | 285 | |

| Stiffness and frequency at design height | Natural frequency Hz | 4.45 | 4.06 | 3.62 | 3.4 | 3.28 | 3.25 | 3.12 | |

| Stiffness and frequency at design height | Natural frequency cpm | 267 | 244 | 217 | 204 | 197 | 195 | 187 |

PURCHASE ORDER DATA

| Type | Air Inlet | Order No. | |

| with crimped plates |

1/4 NPT 0 in. excentrical |

||

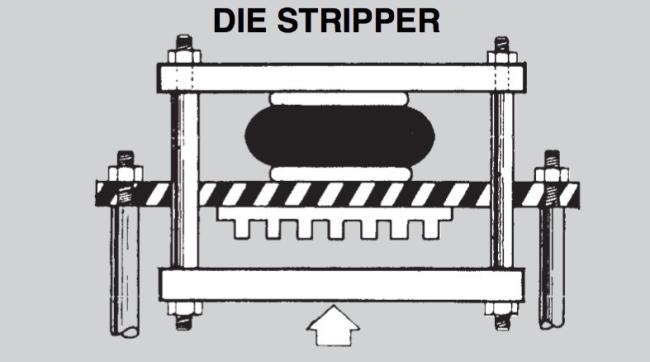

AIRSUSTECH1B8X4

air

spring

is

used

in

DIE

STRIPPER:

In

each

cycle

of

injection

molding,

the

plastic

part

must

be

ejected

from

the

mold

cavity

or

the

insert.

The

mechanism

of

this

ejection

of

the

plastic

part

in

the

mold

is

called

the

ejection

mechanism

(or

the

ejection

mechanism,

the

ejector

mechanism).

The

function

of

the

demoulding

mechanism

includes

two

actions:

ejection

and

removal,

that

is,

firstly,

the

plastic

parts

and

the

pouring

system

condensate

are

loosened

and

separated

from

the

mold,

which

is

called

ejection,

and

then

the

protruding

material

is

taken

out

from

the

mold.

2.7.1

Classification

of

demolding

mechanism:

1,

according

to

the

driving

mode

(1)

Manual

demoulding

(2)

Motorized

demolding

(3)

Hydraulic

demolding

(4)

Pneumatic

demolding

2,

according

to

the

action

of

the

release

mechanism

(1)

Primary

ejection

mechanism

(2)

Secondary

ejection

mechanism

(3)

Delayed

action

ejection

mechanism

3,

according

to

the

ejection

parts

in

the

mold

(1)

Push

rod

type

demoulding

(2)

Push

tube

type

demoulding

(3)

Push

plate

type

demoulding

4.

Hybrid

classification

With

the

variety,

size

and

shape

of

plastic

parts,

there

are

many

types

of

demolding

mechanisms.

It

is

inconvenient

to

divide

by

the

same

standard.

In

production

practice,

the

mixed

method

is

more

practical

and

intuitive.