Supply Tesla batteries insulating ,PP sheet production line

Jul 21, 2025

23 views

Chat Now

Here is an edited introduction to GWELL PP Sheet Extrusion Lines, incorporating technical specifications, applications, and innovations from the search results:

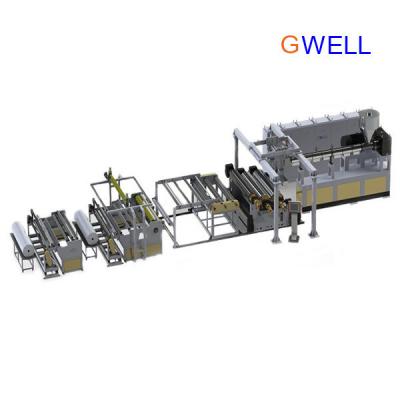

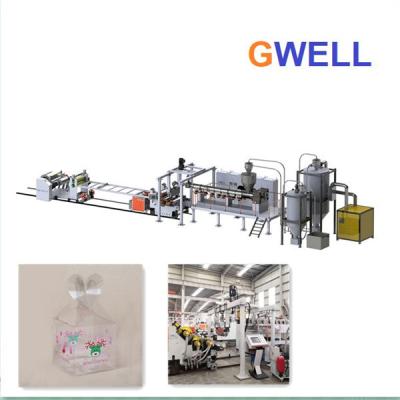

GWELL PP Sheet Extrusion Line: Technology & Applications

Company Profile

GWELL Machinery is a leading Chinese high-tech enterprise specializing in plastic extrusion solutions, with manufacturing bases in Suzhou (Taicang) and Yancheng covering 150,000+ m² . Established in 2010, the company produces 200+ extrusion lines annually and exports globally to markets like Germany, Japan, and Russia .

Technical Highlights

1. Multi-Layer Co-Extrusion Technology

• Produces 3-layer PP/PS/PET sheets with widths of 800–1,500 mm and thicknesses of 0.15–1.5 mm .

• Combines materials like PETG+APET+PETG (GAG structure) for enhanced barrier properties .

• Output capacity: 300–1,500 kg/h, adaptable to single/twin-screw extruders .

2. Precision Control & Efficiency

• Real-time monitoring of temperature, speed, and thickness via CE-certified automation systems .

• Twin-screw venting extruders eliminate pre-drying for PET/PLA, reducing energy use by 30% .

• Modular design enables rapid product switching (e.g., from PP films to flame-retardant sheets) .

3. Specialized Line Configurations

• PP Hollow Sheet Lines: Produce lightweight boards (2–8 mm thick) for logistics packaging, with outputs up to 350 kg/h .

• PP Foam Sheet Lines: Density options (0.3–0.6 g/cm³) for automotive interiors (e.g., sound insulation) and fold-resistant stationery .

• Decorative Film Lines: Speed up to 200 m/min for wood-grain films, supporting high-fill calcium carbonate for cost savings .

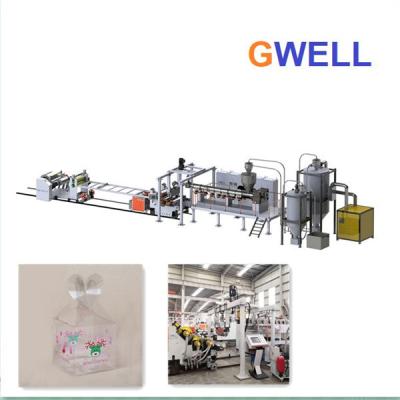

Key Applications

Industry Products Features

Packaging Food containers, battery wraps (e.g., PP cell films), conductive PS sheets High barrier, anti-static, EMI shielding

Construction PP hollow formwork, partition boards 50+ reuse cycles, waterproof, eco-friendly

Automotive Carpet backing, sun visors, luggage racks High impact resistance, noise reduction

Consumer Goods Furniture laminates, flame-retardant films, biodegradable PLA packaging Deep embossing, recyclability

Innovation & Sustainability

• 5/7-layer asymmetric extrusion for high-barrier food packaging (e.g., EVOH/PP composites) .

• PP construction templates replacing wood, aligning with China’s "plastic instead of wood" policy .

• Solar EVA film and stone paper projects supporting circular economies .

Why Choose GWELL?

• Turnkey Solutions: From R&D to installation/debugging, with 1-year warranties .

• Global Compliance: CE certification and ISO-quality manufacturing .

• Customization: Lines tailored to width, output, and material needs (e.g., PP foam densities) .

---

Summary

GWELL’s PP sheet extrusion lines merge versatility, precision, and eco-efficiency, serving industries from green packaging to new energy. With 600+ annual production capacity and a focus on R&D , GWELL delivers scalable, sustainable extrusion technology for global markets.

For technical details or project quotes, contact:

Liam:saled@gwell.cn / +86 15906224102

Max:salem@gwell.cn / +86 15906227399

-

EVA Solar Cell Encapsulation Film Production Line EVA Solar Film Making Machine

View Detail -

EVA Solar Film Making Machine EVA Film Production Line Quality After Sales Service

View Detail -

EVA Solar Film making machine Eva Film Production Line Quality after-sales service

View Detail -

HDPE Thick Board Extrusion Line HDPE Sheet production machine

View Detail -

Pet Sheet Making Machine PET Thermoforming Extrusion Process

View Detail -

ABS PP PE Board Extrusion Line for Cabinets and Outdoor Signs

View Detail -

PP Thick Sheet Production Line PP Thick Board Extruder Machine Single Screw Extruder

View Detail