| Price | Negotiate |

| MOQ | 5 PCS |

| Delivery Time | 5 working days |

| Brand | Shine Abrasives |

| Place of Origin | CHINA |

| Certification | ISO |

| Model Number | 1A1R |

| Packaging Details | 5 pcs in one paper box |

| Payment Terms | L/C, T/T |

| Supply Ability | 5000 PCS per week |

| Grit Size | 100# | Place of Origin | CHINA |

| Shape | 1A1R | Packaging Details | 5 pcs in one paper box |

| HS Code | 8207901000 | Model Number | 1A1R |

| Supply Ability | 5000 PCS per week | Certification | ISO |

| Brand Name | Shine Abrasives | Payment Terms | L/C, T/T |

| Thickness | 0.6mm | Price | Negotiate |

| Delivery Time | 5 working days | Minimum Order Quantity | 5 PCS |

| Bond | Resin | Diameter | 5 inch |

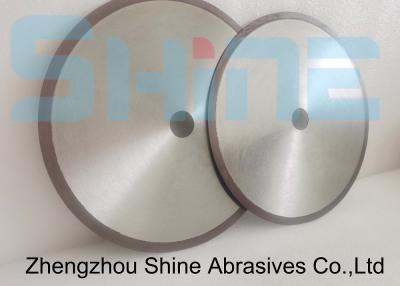

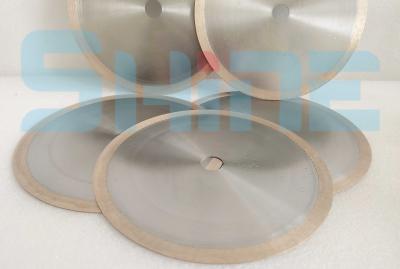

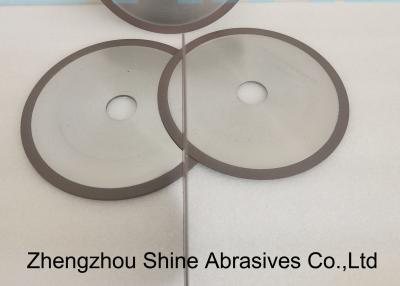

1A1R Diamond Wheels 5 inch Thickness 0.6mm For Carbide Tools Cutting

Shine Abrasives 1A1R Diamond Wheels 5 Inch 125mm diameter For Tungsten Carbide tools Precise Cutting

the cutting off wheels with Resin bond, the thickness is 0.6mm, the wheels bore is 20mm.

Resin diamond cutting discs are suitable for cutting materials:

cemented carbide, tungsten steel, alumina ceramics, zirconia ceramics K9 glass, silicon carbide ceramics, magnetic materials, etc. It can be used for grooving, cutting and grooving.

Drawing of Shine Abrasives 1A1R Diamond Wheels 5 inch Thickness 0.6mm For Carbide Tools Cutting

Main sizes form of Shine Abrasives 1A1R Diamond Wheels 5 inch Thickness 0.6mm For Carbide Tools Cutting

| Abrasive Material:Diamond | Bond Type:Resin |

| Diamond Grit:D126 | Wheel Diameter:5 inch |

| Wheel Bore:20mm | Rim width:5mm |

| Wheel Thickness:0.6mm | Wheel core: Steel |

Other standard sizes also are available as requested.

Features of Shine Abrasives Shine Abrasives 1A1R Diamond Wheels 5 inch Thickness 0.6mm For Carbide Tools Cutting

1. The grinding ability and high wear resistance ensure the insert has a long service life.

2 The high hardness of the binding agent makes the blade have the characteristics of high rigidity, so that the blade can be cut in the process of cutting, so as to ensure the verticality of the cutting surface.

3 Through the fine adjustment of the concentration and particle size of the abrasive, it can have a good cutting efficiency under the premise of meeting the requirements of the cutting surface finish.

4. Scientific processing methods and strict process control ensure that the shape and size of the blade have high precision.

The classification of 5 binders meets the requirements of selecting blades for processing different materials.

The basic structure of this series of products is that the middle is metal material, and the outer ring is diamond working layer.

By choosing different types of bonding agents, it can be suitable for cutting and grooving of various materials.