| Price | Negotiate |

| MOQ | 2 PCS |

| Delivery Time | 5 working days |

| Brand | Shine Abrasives |

| Place of Origin | CHINA |

| Certification | ISO |

| Model Number | 14F1 |

| Packaging Details | 1 pcs in one paper box |

| Payment Terms | L/C, T/T |

| Supply Ability | 10000 pcs per week |

| Grit Size | B107 | Place of Origin | CHINA |

| Shape | 14F1 | Packaging Details | 1 pcs in one paper box |

| HS Code | 6804221000 | Model Number | 14F1 |

| Supply Ability | 10000 pcs per week | Certification | ISO |

| Brand Name | Shine Abrasives | Payment Terms | L/C, T/T |

| Price | Negotiate | Delivery Time | 5 working days |

| Minimum Order Quantity | 2 PCS | Body Materials | Steel |

| Bond | Electroplated | Diameter | 4 inch 100mm |

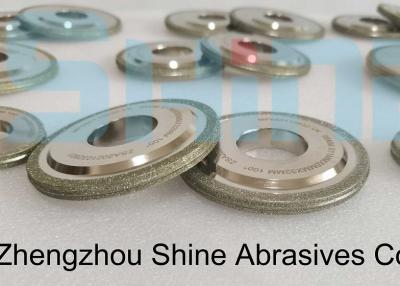

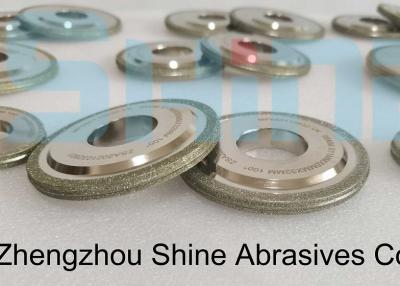

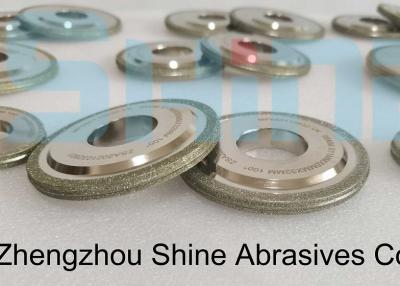

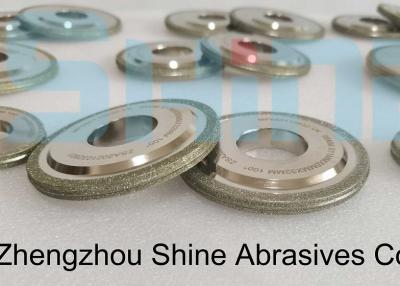

Electroplated Diamond Wheels For Tungsten Carbide Profile Grinding

Shine Abrasives Electroplated Diamond Wheels 100mm For Tungsten Carbide Profile Grinding

Tungsen carbide tools like saw blade,cutters,

Electoplated CBN for steel tools profile or radius grinding.

Specifications of Shine Abrasives Electroplated Diamond Wheels For Tungsten Carbide Profile Grinding

| Abrasive Material:Diamond | Bond Type:Electroplated |

| Radius:1.0mm | Diamond Grit:100 grit |

| Body Materials:steel | Wheel Diameter: 4 inch 100mm |

| Wheel Thickness:10mm | Wheel Bore: 31.75mm |

| Wheel Type:14F1 | Wheel Weight:0.3kgs/PC |

Other sizes also are available as requested.

Features of Shine Abrasives Electroplated Diamond Wheels For Tungsten Carbide Profile Grinding

More aggressive electroplated bond

Lower initial working costs

High good working performance

Long-lasting durability for extended usage

Question:

What's the advantages of electroplated Diamond grinding wheels?

Electroplated Diamond or Cubic Boron Nitride (CBN) grinding wheels usual have a single layer of abrasive held by a tough,

durable nickel alloy. Unlike sintered (metal bond) or resin bond Diamond or CBN wheels in which the abrasive diamond particles are buried in the bond and held together by a metal or resin binder, electroplated products allow the diamond particles to protrude from the surface for maximum abrasive particle exposure. Experience freer, faster cutting action with minimum heat generation.

Wheels can be made for any special shapes, don't need consider the wheel mould like resin or metal bond wheels.

Application picture for reference.