| Price | Negotiate |

| MOQ | 1 PCS |

| Delivery Time | 5 working days |

| Brand | Shine Abrasives |

| Place of Origin | CHINA |

| Certification | ISO |

| Model Number | 1A1 |

| Packaging Details | 1 pcs in one wood box |

| Payment Terms | L/C, T/T |

| Supply Ability | 1000 PCS per week |

| Grit Size | D126 | Place of Origin | CHINA |

| Shape | 1A1 Straight | Diamond Rim Size | 38x20mm |

| Packaging Details | 1 pcs in one wood box | HS Code | 6804211000 |

| Model Number | 1A1 | Supply Ability | 1000 PCS per week |

| Certification | ISO | Brand Name | Shine Abrasives |

| Payment Terms | L/C, T/T | Bond Type | Resin |

| Price | Negotiate | Delivery Time | 5 working days |

| Minimum Order Quantity | 1 PCS | Diameter | 850mm |

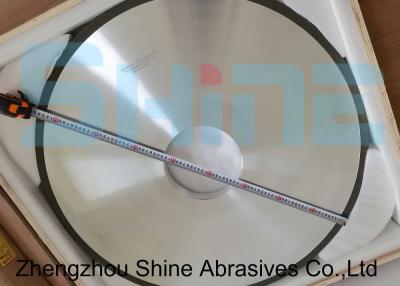

1A1 Diamond Wheels 850mm For Tungsten Carbide Coating Thermal Spray

Shine Abrasives Resin bond 1A1 Resin bond Diamond Wheels 850mm diameter.

Mainly used for grinding HVOF (High Velocity Oxy-Fuel) Tungsten Carbide Coatings

Ceramic Coating ,Aluminum Oxide Coatings,Chrome Oxide Ceramic Coatings

Flame Spray Coating.

Other carbide tools OD grinding.

The drawing of Shine Abrasives 1A1 Diamond Wheels 850mm For Tungsten Carbide Coating Thermal Spray

Main sizes form of Shine Abrasives 1A1 Diamond Wheels 850mm For Tungsten Carbide Coating Thermal Spray

| Abrasive Material:Diamond | Bond Type:Resin |

| CBN Grit:D126 | Wheel Diameter: 850mm |

| Wheel Bore:203.2mm | Wheel Weight:135kgs/PC |

| Wheel Body Material:Aluminum | Diamond Ring Width:20mm |

| Wheel Thickness:38mm | Concentrate: 100% |

Other standard sizes also are available as requested.

Question:

What's HVOF (High Velocity Oxy-Fuel) Tungsten Carbide Coatings?

HVOF devices are a subset of flame spray. There are two distinct differences between conventional flame spray and HVOF.

HVOF utilizes confined combustion and an extended nozzle to heat and accelerate the powdered coating material.

Typical HVOF devices operate at hyper sonic gas velocities,

The extreme velocities provide kinetic energy which help produce coatings that are very dense and very well adhered

in the as-sprayed condition.

Application picture for reference