| Price | FOB |

| MOQ | 2 pcs |

| Delivery Time | 5 work days |

| Brand | Shine Abrasives |

| Place of Origin | China |

| Certification | ISO |

| Model Number | 4V2 1A1 14A2 |

| Packaging Details | one in paperbox |

| Payment Terms | L/C, T/T |

| Supply Ability | 1000 PCS in one week |

| Shape | Cylindrical | Packaging Details | one in paperbox |

| Country Of Origin | China | Abor Hole | 12mm,22mm,50mm |

| Bonding Material | Metal | Supply Ability | 1000 PCS in one week |

| Packing | packed in cartons or others | Minimum Order Quantity | 2 pcs |

| Coolant Required | Yes | Body Materials | Aluminum |

| Features | High cutting efficiency and long lifespan | Place of Origin | China |

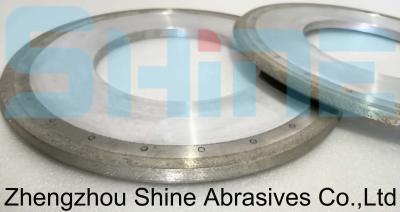

| Diamond Rim Size | 5x10mm | Hole Size | Customized |

| Coolant Type | Dry, Wet | Model Number | 4V2 1A1 14A2 |

| Certification | ISO | Brand Name | Shine Abrasives |

| Payment Terms | L/C, T/T | Grain Size | Coarse |

| Price | FOB | Delivery Time | 5 work days |

| Suitable Materials | Metal, Ceramic, Glass, Stone | Package Quantity | 1 |

| Arbor Hole | 22mm,25mm,31.75mm |

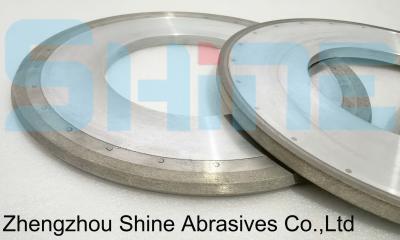

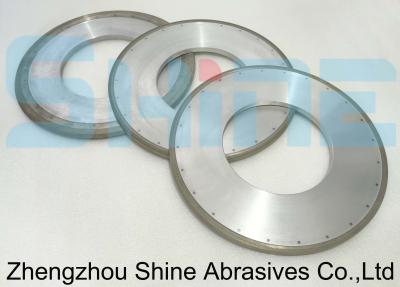

Shine Abrasives Metal bond diamond wheels are specifically designed for grinding hard and brittle materials like glass and ceramics. The metal bond securely holds diamond abrasives, providing durability and stability during the grinding process.Dressing a metal bond diamond wheel is crucial for maintaining its performance and efficiency. By following these steps and employing the right tools and techniques, you can ensure that your wheel remains in optimal condition, providing consistent results in your grinding applications. Regular dressing will extend the life of the wheel and improve the quality of your work.

| Type | 1A1 Flat metal bond diamond grinding wheel |

| Concentration | 50%,75%,125%,150% |

| Mesh |

46#,60#,80#,100#,120#(coarse grinding);

120#,150#,180#,200#,240#(medium

grinding);

280#,320#,400#,500#,600#(fine

grinding);

800#,1000#,1200#,1500#,2000#,3000#(polishing)

|

| Specification |

D75-H10-T5-X10 D150-H19-X5-T5

D125-T10-X10-H20/31.75

D100-T10-X10-H20/31.75

D175-H127-X4-T5

D250-H40-X10-T3

D300-H127-X10-T40

D350-H127-T20-X10

D400-H127-T40-X10

D500-H203-X10-T32

Specification

sizes

can

be

customized

|

| Application | ard alloy,high alumina porcelain,optical glass agate gemstone, semiconductor material,ceramics,stone,etc |

Tools

and

Materials

Needed

Dressing

tool

(diamond

dresser

or

rotary

dressing

tool)

Grinding

machine

Coolant

(if

applicable)

Safety

glasses

and

gloves

Measuring

tools

(optional,

for

checking

wheel

profile)

Steps

to

Dress

the

Wheel

Safety

Precautions