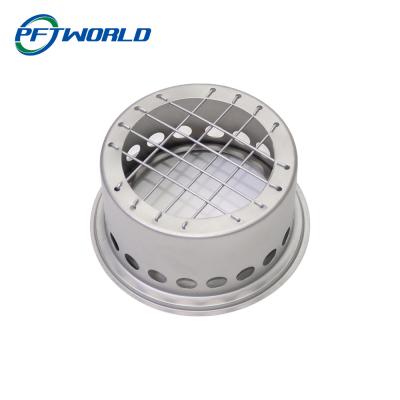

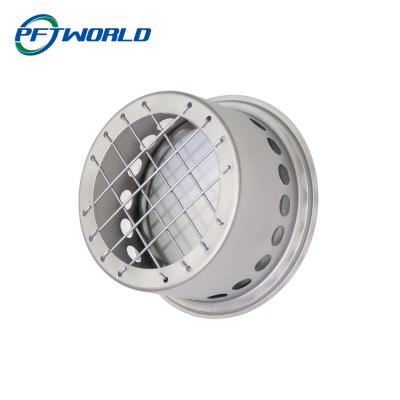

Precision

Spinning

Accessories,

Sheet

Metal

Parts,

Custom

Filter

Quick

details:

1.

Keyword:

Sheet

Metal Parts

2.

Process:

Sheet

Metal

Fabrication

3.

Color:

Any

4.

Place

of

Origin:

Guangdong,

China

5.

Application:

Any

6.

Drawing

Format:

2D/(PDF/CAD)3D(IGES/STEP)

7.

Lead

time:

1-2

weeks

Description:

Stainless

steel

sheet

metal

parts

processing

an

indispensable

process

is

bending,

the

so-called

bending

is

the

use

of

pressure

to

force

the

material

to

produce

deformation,

forming

a

certain

Angle

and

curvature

shape

of

a

stamping

process.

Commonly

used

bending

including

V

-

bending,

Z

-

bending,

and

bending

pressure

equality.

In

bending

the

most

important

is

to

pay

attention

to

these

points:

bending

height,

bending

radius,

bending

direction,

and

pay

attention

to

the

clearance

of

bending,

this

page

is

a

past

customer

custom

Z-shaped

bending

products,

stainless

steel

bending

has

a

certain

difficulty,

usually

used

for

bending

stainless

steel

301

stainless

steel

and

304

stainless

steel.

301

stainless

steel

due

to

good

ductility,

in

the

bending

process,

can

be

better

deformation,

304

stainless

steel

is

the

most

common

stainless

steel

application.

Shenzhen

Perfect

Precision

Products

Co.,

Ltd.

as

a

manufacturer

with

rich

industry

experience,

has

a

wealth

of

experience

with

customers

in

the

production

of

various

kinds

of

customized

products,

sheet

metal

parts

and

machining

parts

or

3

d

printing

or

plastic

parts,

we

have

sufficient

power

production,

according

to

customers’

requirements

to

choose

the

most

appropriate

materials

and

the

most

appropriate

process,

The

most

suitable

processing

method

to

produce

the

highest

quality

products.

Specification:

|

Material

|

Stainless

Steel

|

|

Application

|

Any

|

|

Color

|

Any

|

|

Package

|

Carton

Box

|

|

Surface

treatment

|

Testure/Sand/MT/YS/SPI/VDI

|

|

Drawing

format

|

2D/(PDF/CAD),3D(IGES/STEP)

|

|

Certificates

|

ISO9001:2015/ISO13485:2016

|

|

Lead

time

|

1-2

weeks

|

FAQ

Q1:

is

your

organization

committed

to

the

concept

of

total

quality

management?

A1:

Yes,

no

matter

whether

in

laser

cutting,

bending,

or

CNC

machining,

the

workers

will

conduct

the

first

sample

inspection

and

random

inspection

during

the

processing

to

ensure

the

quality

of

the

products.

Q2:

How

many

checks

are

performed

on

a

project?

A2:

Usually,

products

will

go

through

the

following

four

inspections:

incoming

inspection,

production

first

inspection,

sampling

inspection,

and

pre-shipment

inspection.

Among

them,

sampling

inspection

will

be

conducted

multiple

times.

Q3:

will

you

be

able

to

work

with

our

engineering

team

to

review

drawings

and

provide

quick,

estimated

pricing

for

desired

changes?

A3:

Yes,

our

engineers

respond

very

quickly.

If

there

is

anything

to

be

modified

in

the

product,

we

can

offer

you

a

new

price

as

soon

as

you

tell

us.

Q4:

What

kinds

of

information

do

you

need

for

a

quote?

A4:

Kindly

please

provide

the

product

drawing

in

PDF

and

will

be

better

if

you

can

provide

it

in

DWG/STP/IGS.