| Price | $10-100 |

| MOQ | 1PCS |

| Delivery Time | about 7-15 days according to the quantity |

| Brand | 7 Swords |

| Place of Origin | Shenzhen.China |

| Certification | CE |

| Model Number | OEM |

| Packaging Details | PP bag. Plastic box. Tin box.etc |

| Payment Terms | T/T, L/C, D/P |

| Supply Ability | negotiable |

| Quality System | ISO9001 | Shape | Round, Square, Hexagonal, etc. |

| Packaging Details | PP bag. Plastic box. Tin box.etc | The Tolerance | ±0.01mm |

| Process | CNC Lathe Processing | Supply Ability | negotiable |

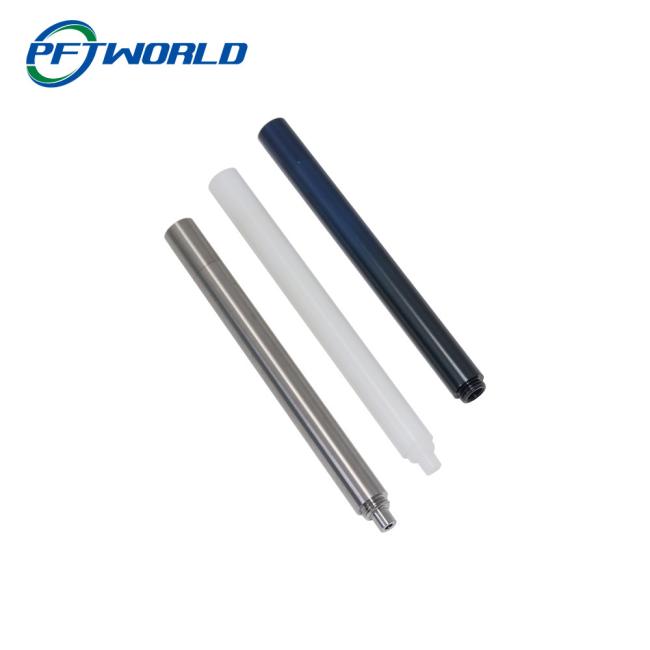

| Type Of Machining | Precision CNC TURNING CNC LATHING | Item | Machining Metal Part |

| Machining Equipment | CNC Automatic Lather | Surface Roughness | Ra 0.4-1.6 μm |

| Minimum Order Quantity | 1PCS | Place of Origin | Shenzhen.China |

| Cnc machining or not | CNC Machining | Color | Customer's Demand |

| Tolerance | 0.01-0.05mm or Customized | Service | OEM/ODM |

| Specification | Custom by 2D/3D/drawing | Model Number | OEM |

| Certification | CE | Surface treatment | Anodizing,Brush,Polish |

| Weight | Customized | Brand Name | 7 Swords |

| Payment Terms | T/T, L/C, D/P | Services | OEM/ODM service |

| Price | $10-100 | Delivery Time | about 7-15 days according to the quantity |

| Delivery | 5-15 days ( based on order quantity) |

Custom CNC machined aluminum oxidized parts refer to aluminum components that are precisely manufactured using CNC (Computer Numerical Control) technology, followed by an oxidation process to enhance their surface properties. CNC machining allows for intricate, detailed, and accurate production of aluminum parts, while the oxidation process forms a protective layer on the surface, increasing corrosion resistance and improving the part’s overall performance.

Aluminum oxidation, commonly known as anodizing, is an electrochemical process that thickens the natural oxide layer on the surface of the aluminum. This process not only improves the material’s durability but also allows for customization through color options and enhanced surface hardness.

Benefits of Custom CNC Machined Aluminum Oxidized Parts

1.Enhanced

Corrosion

Resistance

One

of

the

primary

advantages

of

custom

CNC

machined

aluminum

oxidized

parts

is

their

exceptional

resistance

to

corrosion.

The

anodizing

process

creates

a

protective

oxide

layer

on

the

surface

of

the

aluminum,

preventing

rust,

oxidation,

and

deterioration

even

in

harsh

environments.

This

makes

them

ideal

for

use

in

industries

such

as

aerospace,

automotive,

and

marine,

where

components

are

exposed

to

moisture,

chemicals,

and

extreme

temperatures.

2.Improved Surface Hardness The anodization process increases the surface hardness of aluminum, making custom CNC machined aluminum oxidized parts more resistant to wear, scratches, and other physical damage. This hardness is crucial in applications where the part will be exposed to heavy usage or friction, such as in mechanical components, tooling, and industrial machinery.

3.Lightweight Yet Strong Aluminum is a lightweight material that maintains its strength and performance even after the anodization process. Custom CNC machined aluminum oxidized parts offer the perfect balance between strength and weight, making them ideal for industries such as aerospace and automotive, where reducing weight while maintaining strength is crucial for efficiency and performance.

4.Superior Aesthetic Appeal Anodizing not only increases the durability of aluminum parts but also provides the opportunity to customize their appearance. The anodized surface can be colored in various shades, adding a unique, professional finish that is resistant to fading or peeling. This makes custom CNC machined aluminum oxidized parts a great choice for consumer-facing products where aesthetics and design are important, such as electronics, automotive parts, and architectural components.

5.Customization to Exact Specifications The flexibility of CNC machining combined with anodization allows manufacturers to create parts that meet highly specific requirements. Custom CNC machined aluminum oxidized parts can be tailored in terms of dimensions, geometry, surface finish, and color, ensuring they are optimized for the intended application. Whether you need a simple bracket, a complex housing, or a precision component, CNC machining can achieve the required results with exceptional accuracy.

The CNC Machining and Oxidation Process

The

manufacturing

of

custom

CNC

machined

aluminum

oxidized

parts

involves

two

key

processes:

Applications of Custom CNC Machined Aluminum Oxidized Parts

Factory

Customization

for

Your

Specific

Needs

Custom CNC machined aluminum oxidized parts offer the perfect combination of precision, durability, and aesthetic appeal for a wide range of industries. Through the power of CNC machining and the benefits of anodization, these parts provide excellent performance, resistance to corrosion, and versatility in design. Whether you're looking to improve the functionality, strength, or appearance of your components, custom aluminum oxidized parts provide a reliable, cost-effective solution.

By choosing custom CNC machined aluminum oxidized parts, you can ensure that your manufacturing processes meet the highest standards of quality and precision, giving your business a competitive edge in today’s demanding market.

1. Are you a manufacturer or a trading company?