Hey

there,

DIYers,

makers,

and

manufacturing

pros!

Let's

talk

about

something

you

see

every

day

but

probably

never

think

twice

about:

painted

metal

parts.

From

the

sleek

finish

on

your

car's

door

handle

to

the

colorful

casing

on

your

kid's

favorite

toy,

that

perfect

coat

of

paint

isn't

always

applied

by

a

brush

or

a

spray

gun.

Often,

the

real

magic

happens

before

the

paint

even

comes

out.

It

happens

in

the

world

of

painting

surface

stamping

parts.

First

Off,

What

Exactly

Are

We

Talking

About?

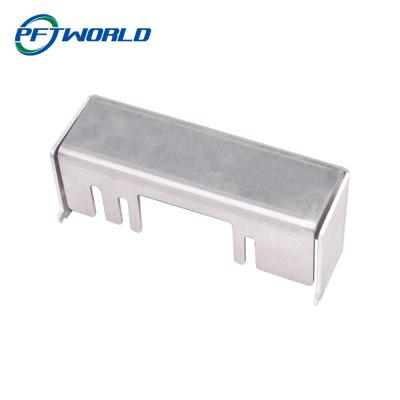

In

simple

terms,

"painting

surface

stamping

parts"

refers

to

metal

components

that

are

shaped

by

a

stamping

press

and

are

specifically

designed

to

be

painted

later.

Think

of

it

like

this:

-

Stamping:

A

giant

machine

uses

a

custom

mold

(a

"die")

to

punch,

bend,

or

shape

a

flat

sheet

of

metal

into

a

specific

part.

It's

like

a

super-powerful

cookie

cutter

for

steel,

aluminum,

or

brass.

-

Painting

Surface:

This

is

the

key.

The

part

isn't

just

any

shape;

it's

engineered

with

its

final

painted

finish

in

mind.

Every

curve,

every

angle,

and

every

surface

is

designed

to

hold

paint

perfectly.

So,

it's

not

just

about

making

a

part.

It's

about

making

a

part

that's

a

perfect

canvas

for

paint.

Why

Does

This

"Canvas"

Matter

So

Much?

You

can't

just

slap

paint

onto

any

metal

surface

and

hope

for

the

best.

A

bad

surface

leads

to

a

bad

paint

job—it

chips,

peels,

and

looks

terrible.

Here’s

why

focusing

on

the

stamped

surface

is

a

game-changer:

-

Smooth

Operator:

The

stamping

process

and

subsequent

treatments

(like

grinding

or

polishing)

ensure

the

surface

is

free

from

bumps,

pits,

and

rough

spots.

A

smooth

start

means

a

smooth,

glossy

finish.

-

Clean

Slate:

Stamped

parts

are

almost

always

cleaned

and

treated

before

painting.

This

involves

processes

like

degreasing

(to

remove

oils)

and

phosphating

(which

creates

a

microscopic

layer

that

helps

paint

stick

like

glue).

This

prevents

the

paint

from

flaking

off.

-

Durability

You

Can

Count

On:

When

paint

properly

adheres

to

a

perfectly

prepared

surface,

the

final

product

can

withstand

the

elements—rain,

sun,

scratches,

and

daily

wear

and

tear.

That's

why

this

process

is

crucial

for

automotive

and

appliance

parts.

The

Stamping

Difference:

It's

All

in

the

Details

What

makes

a

stamped

part

a

better

candidate

for

painting

than,

say,

a

part

made

another

way?

-

Consistency

is

King.

A

stamping

press

churns

out

thousands

of

identical

parts.

This

means

every

single

part

has

the

exact

same

surface

quality,

ready

for

the

paint

line.

No

surprises.

-

Complex

Shapes,

No

Problem.

Stamping

can

create

intricate

designs

with

tight

bends

and

complex

geometries.

A

good

stamping

process

ensures

that

even

these

tricky

areas

are

accessible

and

properly

prepared

for

a

uniform

coat

of

paint.

-

Material

Mastery.

Stamping

works

with

metals

that

are

known

for

taking

paint

well,

like

cold-rolled

steel

and

certain

aluminum

alloys.

The

material

choice

is

part

of

the

overall

strategy

for

a

flawless

finish.

Bringing

It

All

Together

So,

the

next

time

you

admire

the

flawless,

durable

paint

on

a

product,

remember:

the

credit

doesn't

just

go

to

the

paint

itself

or

the

painter.

A

huge

part

of

that

success

comes

from

the

unsung

hero—the

meticulously

prepared

stamped

part

underneath.

It’s

a

perfect

partnership:

stamping

creates

the

perfect

form,

and

painting

provides

the

beautiful,

protective

function.

Looking

for

reliable,

paint-ready

stamped

parts

for

your

project

or

production

line? It's

worth

cooperating

with

us.

|

|

CNC

Turning,

CNC

Milling,

Laser

Cutting,

Bending,

Spining,

Wire

Cutting,

Stamping,

Electric

Discharge

Machining

(EDM),

Injection

Molding,3D

Printing,Rapid

Prototype,Moulds

etc.

|

|

|

Aluminum:

2000

series,

6000

series,

7075,

5052,

etc.

|

|

Stainlesss

steel:

SUS303,

SUS304,

SS316,

SS316L,

17-4PH,

etc.

|

|

Steel:

1214L/1215/1045/4140/SCM440/40CrMo,

etc.

|

|

Brass:

260,

C360,

H59,

H60,

H62,

H63,

H65,

H68,

H70,

Bronze,

Copper

|

|

Titanium:

Grade

F1-F5

|

|

Plastic:

Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK

etc.

|

|

|

Anodized,

Bead

Blasted,

Silk

Screen,

PVD

Plating,

Zinc/Nickl/Chrome/Titanium

Plating,

Brushing,

Painting,

Powder

Coated,

Passivation,

Electrophoresis,

Electro

Polishing,

Knurl,

Laser/Etch/Engrave

etc.

|

|

|

±0.002

~

±0.005mm

|

|

|

Min

Ra

0.1~3.2

|

|

CERTIFICATE

|

ISO9001:2015,AS9100D,ISO13485:2016,ISO45001:2018,IATF16949:2016,ISO14001:2015,ROSH,CE

etc.

|

FAQ

1.

Are

you

a

manufacturer

or

a

trading

company?

We

are

a

factory

located

in

Shenzhen,

China,

with

20

years

of

rich

experience,

covering

6000

square

meters.

Complete

facilities,

including

3D

quality

inspection

equipment,

ERP

system

and

40

machines.

If

necessary,

we

can

provide

you

with

material

certificates,

sample

quality

inspection

and

other

reports.

2.

How

to

get

a

quote?

Detailed

drawings

(PDF/STEP/IGS/DWG...),

including

quality,

delivery

date,

materials,

quality,

quantity,

surface

treatment

and

other

information.

3.

Can

I

get

a

quotation

without

drawings?

Can

your

engineering

team

draw

for

my

creativity?

Of

course,

we

are

also

glad

to

receive

your

samples,

pictures

or

detailed

size

drafts

for

accurate

quotation.

4.

Can

you

provide

samples

before

mass

production?

Of

course,

the

sample

fee

is

necessary.

If

possible,

it

will

be

returned

during

mass

production.

5.

What

is

the

delivery

date?

Generally,

the

sample

lasts

for

1-2

weeks

and

the

batch

production

lasts

for

3-4

weeks.

6.

How

do

you

control

quality?

(1)

Material

Inspection

-

Check

material

surfaces

and

approximate

dimensions.

(2)

First

inspection

of

production

-

ensure

critical

dimensions

in

mass

production.

(3)

Sampling

inspection

-

check

the

quality

before

delivery

to

the

warehouse.

(4)

Preshipment

inspection

-

100%

inspection

by

QC

assistant

before

shipment.

7.

After

sales

service

team

If

you

have

any

problems

after

receiving

the

product,

you

can

provide

feedback

through

voice

call,

video

conference,

email,

etc.

within

one

month.

Our

team

will

provide

you

with

solutions

within

a

week.