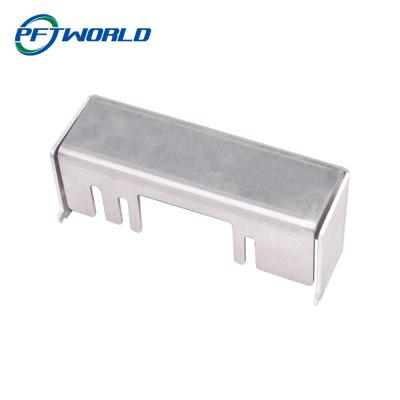

So,

you’ve

got

aluminum

stamped

parts—lightweight,

strong,

and

cost-effective.

But

aluminum

can

corrode,

scratch,

or

just

look

a

little…

plain.

That’s

where

zinc

plating

comes

in.

It’s

like

giving

your

parts

a

protective

jacket

that

also

adds

a

sleek,

professional

finish.

Why

Zinc

Plate

Aluminum

Stamped

Parts?

Aluminum

naturally

forms

an

oxide

layer

that

protects

it

from

corrosion—but

that’s

not

always

enough,

especially

in

harsh

environments.

Zinc

plating

adds

an

extra

layer

of

defense

and

brings

other

benefits

too:

-

Corrosion

Resistance:

Zinc

acts

as

a

sacrificial

layer,

meaning

it

corrodes

before

the

aluminum

does.

-

Better

Appearance:

You

get

a

clean,

shiny

finish

(usually

silver,

black,

or

blue).

-

Improved

Durability:

The

coating

helps

resist

wear

and

minor

abrasion.

-

Solderability:

Zinc-plated

surfaces

can

be

easier

to

solder,

depending

on

the

application.

How

Zinc

Plating

Works

on

Aluminum

A

good

plating

process

usually

includes

these

stages:

-

Cleaning:

Removing

oils,

dirt,

or

residues

from

the

stamping

process.

-

Etching:

Mild

acids

prepare

the

surface

by

removing

the

natural

oxide

layer.

-

Zincation:

This

is

the

key

step!

The

aluminum

is

dipped

in

a

zincate

solution,

which

deposits

a

thin

layer

of

zinc

that

other

metals

can

bond

to.

-

Plating:

The

part

goes

into

the

zinc

plating

bath

(often

electroplating).

-

Passivation

(Optional):

A

clear

or

colored

chromate

conversion

coating

can

be

added

for

extra

corrosion

resistance

and

color.

-

Rinsing

&

Drying:

Final

steps

to

seal

the

finish.

Types

of

Zinc

Plating

for

Aluminum

Not

all

zinc

plating

is

the

same.

Common

approaches

include:

-

Electroplating:

Uses

electrical

current

to

bond

zinc—good

for

precise,

even

coatings.

-

Mechanical

Plating:

Zinc

particles

are

cold-welded

to

the

part;

less

risk

of

hydrogen

embrittlement.

-

Zinc-Nickel

Alloy

Plating:

Offers

superior

corrosion

resistance,

ideal

for

automotive

or

aerospace

uses.

Key

Benefits

Summarized

-

Cost-Effective:

Extends

part

life

without

a

major

price

bump.

-

Aesthetic

Flexibility:

Available

in

clear,

blue-bright,

black,

yellow,

and

more.

-

RoHS-Compliant

Options:

Modern

trivalent

chromates

replace

toxic

hexavalent

chrome.

-

Improved

Performance:

Better

conductivity,

hardness,

and

wear

resistance

vs.

bare

aluminum.

Design

&

Stamping

Tips

for

Better

Plating

-

Avoid

sharp

edges—they

attract

more

current

during

plating,

leading

to

uneven

coating.

-

Make

sure

parts

can

be

racked

or

tumbled

easily

for

uniform

plating.

-

Discuss

finish

requirements

early

with

your

stamper

and

plater.

Final

Takeaway

Zinc

plating

aluminum

stamped

parts

is

a

smart,

affordable

way

to

boost

durability

and

aesthetics.

Just

remember—the

secret

is

in

the

prep.

By

collaborating

with

us,

you

will

receive

parts

that

look

great

and

have

a

longer

lifespan.

|

|

CNC

Turning,

CNC

Milling,

Laser

Cutting,

Bending,

Spining,

Wire

Cutting,

Stamping,

Electric

Discharge

Machining

(EDM),

Injection

Molding,3D

Printing,Rapid

Prototype,Moulds

etc.

|

|

|

Aluminum:

2000

series,

6000

series,

7075,

5052,

etc.

|

|

Stainlesss

steel:

SUS303,

SUS304,

SS316,

SS316L,

17-4PH,

etc.

|

|

Steel:

1214L/1215/1045/4140/SCM440/40CrMo,

etc.

|

|

Brass:

260,

C360,

H59,

H60,

H62,

H63,

H65,

H68,

H70,

Bronze,

Copper

|

|

Titanium:

Grade

F1-F5

|

|

Plastic:

Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK

etc.

|

|

|

Anodized,

Bead

Blasted,

Silk

Screen,

PVD

Plating,

Zinc/Nickl/Chrome/Titanium

Plating,

Brushing,

Painting,

Powder

Coated,

Passivation,

Electrophoresis,

Electro

Polishing,

Knurl,

Laser/Etch/Engrave

etc.

|

|

|

±0.002

~

±0.005mm

|

|

|

Min

Ra

0.1~3.2

|

|

CERTIFICATE

|

ISO9001:2015,AS9100D,ISO13485:2016,ISO45001:2018,IATF16949:2016,ISO14001:2015,ROSH,CE

etc.

|

FAQ

1.

Are

you

a

manufacturer

or

a

trading

company?

We

are

a

factory

located

in

Shenzhen,

China,

with

20

years

of

rich

experience,

covering

6000

square

meters.

Complete

facilities,

including

3D

quality

inspection

equipment,

ERP

system

and

40

machines.

If

necessary,

we

can

provide

you

with

material

certificates,

sample

quality

inspection

and

other

reports.

2.

How

to

get

a

quote?

Detailed

drawings

(PDF/STEP/IGS/DWG...),

including

quality,

delivery

date,

materials,

quality,

quantity,

surface

treatment

and

other

information.

3.

Can

I

get

a

quotation

without

drawings?

Can

your

engineering

team

draw

for

my

creativity?

Of

course,

we

are

also

glad

to

receive

your

samples,

pictures

or

detailed

size

drafts

for

accurate

quotation.

4.

Can

you

provide

samples

before

mass

production?

Of

course,

the

sample

fee

is

necessary.

If

possible,

it

will

be

returned

during

mass

production.

5.

What

is

the

delivery

date?

Generally,

the

sample

lasts

for

1-2

weeks

and

the

batch

production

lasts

for

3-4

weeks.

6.

How

do

you

control

quality?

(1)

Material

Inspection

-

Check

material

surfaces

and

approximate

dimensions.

(2)

First

inspection

of

production

-

ensure

critical

dimensions

in

mass

production.

(3)

Sampling

inspection

-

check

the

quality

before

delivery

to

the

warehouse.

(4)

Preshipment

inspection

-

100%

inspection

by

QC

assistant

before

shipment.

7.

After

sales

service

team

If

you

have

any

problems

after

receiving

the

product,

you

can

provide

feedback

through

voice

call,

video

conference,

email,

etc.

within

one

month.

Our

team

will

provide

you

with

solutions

within

a

week.