When

it

comes

to

manufacturing

components

that

require

superior

strength,

precision,

and

resistance

to

environmental

elements,

7075

aluminum

is

one

of

the

most

sought-after

materials

in

industries

like

aerospace,

automotive,

and

defense.

7075

aluminum

bending

sheet

metal

spraying

processing

service

offers

an

advanced

solution

for

creating

high-performance

parts

that

not

only

meet

stringent

specifications

but

also

stand

the

test

of

time.

What

is

7075

Aluminum

Bending

Sheet

Metal

Spraying

Processing?

7075

aluminum

is

an

alloy

known

for

its

exceptional

strength-to-weight

ratio,

making

it

one

of

the

most

popular

choices

in

high-performance

applications.

It

contains

zinc

as

its

primary

alloying

element,

which

contributes

to

its

outstanding

strength,

but

also

makes

it

more

challenging

to

process

compared

to

other

aluminum

alloys.

This

is

where

7075

aluminum

bending

and

sheet

metal

spraying

processing

come

into

play.

-

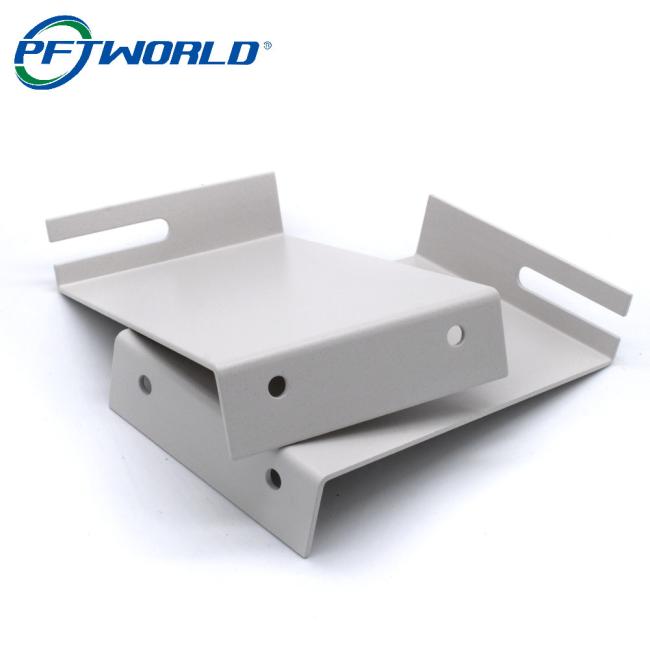

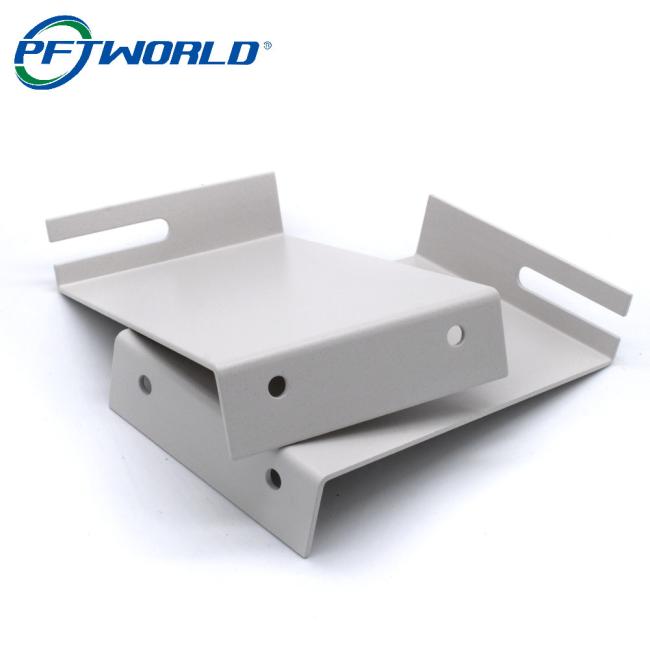

Bending:

Aluminum

bending

is

the

process

of

forming

the

material

into

precise

angles

or

shapes,

typically

using

specialized

equipment

like

press

brakes

or

roll

benders.

For

7075

aluminum,

which

is

known

for

its

high

strength

and

toughness,

precise

control

during

the

bending

process

ensures

that

the

material

retains

its

structural

integrity

while

achieving

the

desired

shape.

The

bending

process

can

produce

complex

designs

with

tight

tolerances,

which

is

ideal

for

aerospace,

automotive,

and

other

engineering

applications.

-

Spraying:

Sheet

metal

spraying

refers

to

the

application

of

a

protective

coating

or

finish

to

the

surface

of

the

aluminum

part.

This

is

typically

done

through

processes

such

as

powder

coating,

electrostatic

spraying,

or

anodizing.

These

coatings

enhance

the

material's

resistance

to

corrosion,

wear,

and

environmental

exposure

while

also

providing

an

aesthetically

pleasing

finish.

Spraying

also

offers

the

option

for

customized

colors,

textures,

and

finishes,

giving

parts

a

unique

look

that

can

match

the

specific

needs

of

the

product

or

application.

Together,

7075

aluminum

bending

sheet

metal

spraying

processing

delivers

a

comprehensive

solution

for

creating

components

that

are

not

only

strong

and

precise

but

also

protected

from

the

elements

and

designed

to

meet

the

aesthetic

requirements

of

various

industries.

Benefits

of

7075

Aluminum

Bending

Sheet

Metal

Spraying

Processing

-

Exceptional

Strength-to-Weight

Ratio:

One

of

the

standout

features

of

7075

aluminum

is

its

strength-to-weight

ratio.

It

is

incredibly

strong

compared

to

many

other

aluminum

alloys,

making

it

ideal

for

use

in

industries

where

both

weight

and

strength

are

critical,

such

as

aerospace

and

automotive.

The

bending

process

preserves

these

material

properties,

ensuring

that

the

final

part

remains

lightweight

without

compromising

on

strength.

-

Corrosion

and

Wear

Resistance:

When

7075

aluminum

undergoes

sheet

metal

spraying,

it

can

be

coated

with

a

variety

of

finishes

that

protect

it

from

corrosion

and

wear.

These

finishes

create

a

barrier

against

moisture,

chemicals,

and

extreme

environmental

conditions,

making

the

material

suitable

for

applications

in

marine

environments,

outdoor

equipment,

or

any

setting

where

the

parts

will

be

exposed

to

harsh

conditions.

-

Precision

and

Customization:

The

bending

process

is

highly

precise,

allowing

manufacturers

to

create

parts

with

complex

geometries,

tight

tolerances,

and

intricate

features.

This

level

of

precision

ensures

that

each

component

fits

perfectly

within

its

intended

system

or

application.

Spraying

further

enhances

this

precision

by

providing

uniform

coverage

and

customizable

finishes

to

meet

both

functional

and

aesthetic

requirements.

-

Durable

Surface

Finishes:

Spraying

processes,

such

as

powder

coating

and

anodizing,

not

only

provide

protection

but

also

enhance

the

surface

appearance

of

the

parts.

Powder

coating,

for

example,

offers

a

tough,

durable

finish

that

resists

scratches

and

fading,

while

anodizing

creates

a

smooth,

hard

surface

that

is

resistant

to

corrosion

and

UV

degradation.

This

is

especially

valuable

for

consumer-facing

products

where

the

appearance

of

the

part

matters

just

as

much

as

its

functionality.

-

Customization

in

Design:

Aluminum

parts

can

be

customized

in

terms

of

color,

texture,

and

finish.

Through

spraying

techniques

like

powder

coating,

manufacturers

can

match

a

specific

color

palette

or

add

a

unique

texture

that

aligns

with

the

product's

design

specifications.

This

makes

7075

aluminum

bending

sheet

metal

spraying

processing

services

highly

versatile

for

various

industries,

including

electronics,

automotive,

and

consumer

goods.

-

Improved

Durability

and

Longevity:

When

you

combine

the

strength

of

7075

aluminum

with

the

added

protection

of

a

sprayed

finish,

you

create

parts

that

are

built

to

last.

The

coating

not

only

improves

the

part's

resistance

to

corrosion

and

wear

but

also

adds

to

its

ability

to

endure

high

mechanical

stresses,

temperature

variations,

and

long-term

exposure

to

the

elements.

Applications

of

7075

Aluminum

Bending

Sheet

Metal

Spraying

Processing

-

Aerospace:

In

the

aerospace

industry,

7075

aluminum

is

widely

used

for

parts

that

need

to

withstand

the

rigors

of

flight,

including

aircraft

wings,

fuselage

components,

and

landing

gear.

The

strength

and

lightweight

nature

of

7075

aluminum,

combined

with

the

bending

and

spraying

process,

produce

parts

that

are

both

highly

durable

and

lightweight—key

factors

for

optimal

aerospace

performance.

-

Automotive:

The

automotive

industry

is

always

seeking

materials

that

provide

strength,

lightweight

properties,

and

resistance

to

environmental

factors.

7075

aluminum

parts

such

as

frames,

suspension

components,

and

body

panels

benefit

from

both

the

bending

and

spraying

processes,

which

improve

their

performance

while

offering

protection

against

corrosion,

chemicals,

and

the

elements.

-

Military

and

Defense:

In

the

defense

sector,

high-performance

materials

are

critical

for

the

manufacture

of

components

used

in

military

vehicles,

equipment,

and

weapons

systems.

The

use

of

7075

aluminum

with

precision

bending

and

spraying

ensures

that

components

meet

the

highest

standards

for

strength,

precision,

and

environmental

resistance,

which

are

required

in

defense

applications.

-

Marine:

The

marine

industry

requires

materials

that

can

withstand

constant

exposure

to

saltwater

and

harsh

weather

conditions.

7075

aluminum’s

natural

corrosion

resistance

is

enhanced

further

by

spraying,

making

it

an

ideal

material

for

components

such

as

boat

frames,

engine

parts,

and

marine

hardware.

-

Outdoor

and

Sporting

Equipment:

Outdoor

products,

including

bicycles,

camping

gear,

and

sports

equipment,

benefit

from

7075

aluminum’s

lightweight

and

strength

properties.

Bending

and

spraying

ensure

that

these

parts

are

both

durable

and

visually

appealing,

providing

an

extra

layer

of

protection

from

the

elements

while

maintaining

a

sleek

appearance.

-

Electronics

and

Consumer

Goods:

The

electronics

industry

uses

7075

aluminum

for

custom

housings,

frames,

and

brackets.

The

precision

bending

process

ensures

these

components

are

manufactured

to

exact

specifications,

while

spraying

provides

a

finished

product

that

is

both

durable

and

visually

appealing.

This

is

crucial

for

high-end

electronic

products

and

accessories.

The

Process

of

7075

Aluminum

Bending

Sheet

Metal

Spraying

-

Design

and

Engineering:

The

process

begins

with

designing

the

component

based

on

the

specific

requirements

of

the

client.

Using

advanced

CAD

software,

engineers

develop

a

3D

model

that

captures

all

necessary

dimensions

and

features

for

precise

bending

and

spraying.

-

Bending:

The

7075

aluminum

sheet

is

fed

into

a

CNC

press

brake

or

roll

bender,

where

it

is

carefully

shaped

according

to

the

CAD

design.

The

bending

process

is

performed

with

high

precision

to

ensure

that

the

material

does

not

fracture

or

distort.

-

Spraying/Coating:

After

the

bending

process,

the

part

undergoes

a

spraying

or

coating

procedure.

Techniques

such

as

powder

coating,

anodizing,

or

electrostatic

spraying

are

applied

to

the

part

to

enhance

its

corrosion

resistance,

aesthetic

appearance,

and

durability.

The

coating

ensures

uniform

coverage

and

protects

the

part

from

harsh

environments.

-

Finishing

and

Quality

Control:

Once

the

spraying

is

complete,

the

part

is

subjected

to

finishing

processes

such

as

curing

or

hardening

(for

powder

coating)

or

sealing

(for

anodized

parts).

The

part

is

then

inspected

for

quality

control,

ensuring

that

it

meets

all

specifications

and

requirements

before

it

is

shipped

to

the

client.

-

Packaging

and

Shipping:

The

finished

parts

are

carefully

packaged

to

prevent

damage

during

transportation.

Manufacturers

ensure

that

each

part

arrives

in

perfect

condition,

ready

for

integration

into

the

client's

product

or

system.

Conclusion

7075

aluminum

bending

sheet

metal

spraying

processing

offers

a

comprehensive

solution

for

producing

high-performance

components

that

combine

strength,

precision,

and

durability.

Whether

for

aerospace,

automotive,

defense,

or

any

other

high-demand

industry,

these

custom

parts

provide

the

necessary

properties

to

meet

tough

specifications

and

stand

up

to

the

elements.

By

combining

the

outstanding

strength

of

7075

aluminum

with

the

precision

of

CNC

bending

and

the

protection

of

spraying,

manufacturers

can

create

custom

parts

that

offer

both

superior

performance

and

an

appealing

finish.

Whether

you're

looking

for

custom

components

for

industrial

machinery,

military

applications,

or

consumer

goods,

7075

aluminum

bending

sheet

metal

spraying

processing

service

is

the

ideal

choice

for

high-quality,

durable,

and

reliable

parts.

|

|

CNC

Turning,

CNC

Milling,

Laser

Cutting,

Bending,

Spining,

Wire

Cutting,

Stamping,

Electric

Discharge

Machining

(EDM),

Injection

Molding,3D

Printing,Rapid

Prototype,Moulds

etc.

|

|

|

Aluminum:

2000

series,

6000

series,

7075,

5052,

etc.

|

|

Stainlesss

steel:

SUS303,

SUS304,

SS316,

SS316L,

17-4PH,

etc.

|

|

Steel:

1214L/1215/1045/4140/SCM440/40CrMo,

etc.

|

|

Brass:

260,

C360,

H59,

H60,

H62,

H63,

H65,

H68,

H70,

Bronze,

Copper

|

|

Titanium:

Grade

F1-F5

|

|

Plastic:

Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK

etc.

|

|

|

Anodized,

Bead

Blasted,

Silk

Screen,

PVD

Plating,

Zinc/Nickl/Chrome/Titanium

Plating,

Brushing,

Painting,

Powder

Coated,

Passivation,

Electrophoresis,

Electro

Polishing,

Knurl,

Laser/Etch/Engrave

etc.

|

|

|

±0.002

~

±0.005mm

|

|

|

Min

Ra

0.1~3.2

|

|

CERTIFICATE

|

ISO9001:2015,AS9100D,ISO13485:2016,ISO45001:2018,IATF16949:2016,ISO14001:2015,ROSH,CE

etc.

|

FAQ

1.

Are

you

a

manufacturer

or

a

trading

company?

We

are

a

factory

located

in

Shenzhen,

China,

with

20

years

of

rich

experience,

covering

6000

square

meters.

Complete

facilities,

including

3D

quality

inspection

equipment,

ERP

system

and

40

machines.

If

necessary,

we

can

provide

you

with

material

certificates,

sample

quality

inspection

and

other

reports.

2.

How

to

get

a

quote?

Detailed

drawings

(PDF/STEP/IGS/DWG...),

including

quality,

delivery

date,

materials,

quality,

quantity,

surface

treatment

and

other

information.

3.

Can

I

get

a

quotation

without

drawings?

Can

your

engineering

team

draw

for

my

creativity?

Of

course,

we

are

also

glad

to

receive

your

samples,

pictures

or

detailed

size

drafts

for

accurate

quotation.

4.

Can

you

provide

samples

before

mass

production?

Of

course,

the

sample

fee

is

necessary.

If

possible,

it

will

be

returned

during

mass

production.

5.

What

is

the

delivery

date?

Generally,

the

sample

lasts

for

1-2

weeks

and

the

batch

production

lasts

for

3-4

weeks.

6.

How

do

you

control

quality?

(1)

Material

Inspection

-

Check

material

surfaces

and

approximate

dimensions.

(2)

First

inspection

of

production

-

ensure

critical

dimensions

in

mass

production.

(3)

Sampling

inspection

-

check

the

quality

before

delivery

to

the

warehouse.

(4)

Preshipment

inspection

-

100%

inspection

by

QC

assistant

before

shipment.

7.

After

sales

service

team

If

you

have

any

problems

after

receiving

the

product,

you

can

provide

feedback

through

voice

call,

video

conference,

email,

etc.

within

one

month.

Our

team

will

provide

you

with

solutions

within

a

week.