| Price | Negotiable |

| MOQ | 1PC |

| Delivery Time | 7-15 work days |

| Brand | PFT |

| Place of Origin | Guangdong, China |

| Certification | ISO9001:2015, ISO13485:2016 |

| Model Number | OEM |

| Packaging Details | As the requirement of customer |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 10000Pcs/ Month |

| Packaging Details | As the requirement of customer | Material Capabilities | Plastic |

| Supply Ability | 10000Pcs/ Month | Chemical Resistance | Strong |

| Minimum Order Quantity | 1PC | Resistance To Chemicals | Yes |

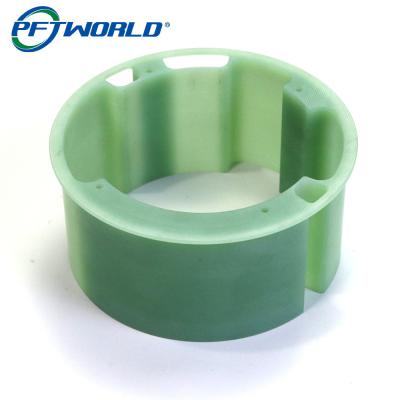

| Finish | Smooth | Quality Control | 100% inspection before shipment |

| Lead Time | 7days | Place of Origin | Guangdong, China |

| Cutting thickness | Materials | Sample | Avaliable |

| Tolerance | ±0.01mm | Service | OEM/ODM |

| Quantity | Customized | Material | Stainless steel, Brass, Aluminum, etc |

| Model Number | OEM | Certification | ISO9001:2015, ISO13485:2016 |

| Brand Name | PFT | Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Resistance | Chemical, Heat, and Wear | Equipment | SLA, 3D printing, HAAS 5 AXIS |

| Price | Negotiable | Delivery Time | 7-15 work days |

| Quality control | ISO9001:2015 certificated | Surface Treatment | None |

| Production Process | CNC Machining | Application | Industrial |

In today’s fast-paced manufacturing landscape, customized CNC machining of precision plastic parts has emerged as a cornerstone of innovation, offering unparalleled versatility, accuracy, and speed. As industries ranging from aerospace to medical devices increasingly turn to plastic components for their lightweight, corrosion-resistant, and cost-effective properties, CNC (Computer Numerical Control) machining provides the precision and repeatability needed to meet stringent quality demands.

What is Customized CNC Machining?

CNC

machining

refers

to

the

automated,

computer-controlled

process

of

removing

material

from

a

solid

block

(or

blank)

to

create

parts

with

tight

tolerances.

Unlike

traditional

machining,

CNC

relies

on

pre-programmed

software

to

control

the

movement

of

tools,

ensuring

consistent

and

accurate

results.

Customization in CNC machining takes this a step further by tailoring each part’s design and production to specific client requirements. This includes unique geometries, specialized surface finishes, and material selections—all optimized for the intended application.

Why Plastics?

Plastics

are

no

longer

just

low-cost

alternatives

to

metals.

Engineering

plastics

like

PEEK,

Delrin

(acetal),

PTFE,

Nylon,

and

UHMW-PE

offer

impressive

mechanical

properties

including:

When machined correctly, these materials can deliver high-performance solutions in demanding environments.

The Benefits of Customized CNC Machining for Plastic Parts

1.Unmatched

Precision

CNC

machines

can

achieve

tolerances

as

tight

as

±0.001

inches,

critical

for

applications

in

medical

devices,

electronics,

and

aerospace

components.

2.Design Flexibility

Complex

geometries

that

would

be

difficult

or

impossible

to

mold

can

be

achieved

through

multi-axis

CNC

machining.

3.Rapid Prototyping and Low-Volume Production

CNC machining is ideal for quickly producing one-off prototypes or small batches without the high upfront costs of injection molds.

4.Superior Surface Finishes

Custom machining allows for smoother surface finishes, reducing the need for secondary operations or post-processing.

5.Material Versatility

CNC machining accommodates a wide range of engineering plastics, each chosen based on chemical resistance, thermal properties, or mechanical strength.

Industries Driving Demand

1. Are you a manufacturer or a trading company?