8x18mm

Medium

Wave

Infrared

Heating

Lamp

500W

for

Plastic

Welding

Product

Specifications

|

Attribute

|

Value

|

|

Keyword

|

Medium

wave

IR

lamp

|

|

Place

of

Origin

|

Guangdong,

China

|

|

Response

time

|

60-90s

|

|

Lifetime

|

20000h

|

|

Material

|

Quartz

|

|

Voltage

|

230V

|

|

Power

|

500W

|

|

Total

length

|

400mm

|

|

Heating

length

|

300mm

|

|

Design

type

|

B

|

Product

Description

500W

8x18mm

Medium

Wave

Infrared

Heating

Lamp

IR

Heater

specifically

designed

for

plastic

welding

applications.

Infrared

Medium

Wave

Introduction

Infrared

medium

wave

radiators

are

ideal

for

heating

surfaces

or

thinner

materials.

Plastics,

water

and

base

materials

absorb

infrared

medium

waves

most

effectively.

These

lamps

feature

low

cost,

high

strength

and

long

lifespan,

making

them

suitable

for

heating

processes

with

most

materials.

Infrared

Heat

Lamp

Advantages

-

Long

service

life:

Over

5000

hours

operation

-

Fast

reaction

time:

Achieves

full

power

output

in

1-2

seconds

-

Energy

efficient:

Gold

and

ceramic

coating

reflects

up

to

90%

of

infrared

radiation

-

Environmentally

friendly:

Non-toxic

with

no

risk

of

contamination

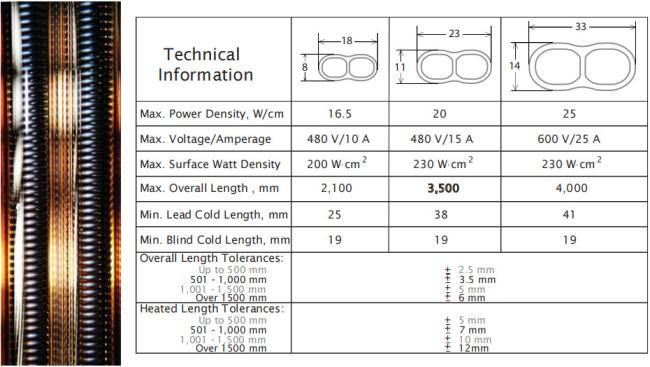

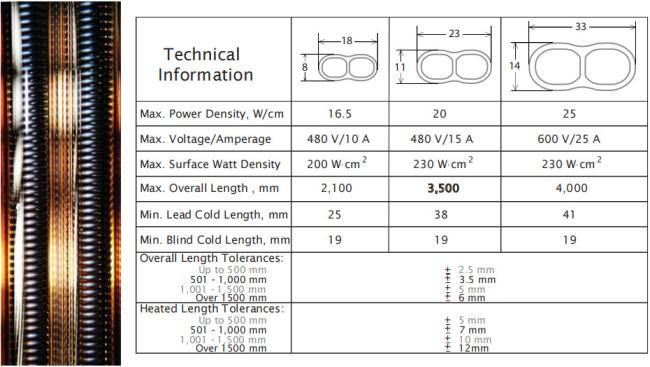

Technical

Parameters

|

Parameter

|

Value

|

|

Product

name

|

Twin

tube

Medium

wave

infrared

lamp

|

|

UVIR

NO.

|

TMG100007

|

|

Power

|

500W

|

|

Voltage

|

230V

|

|

Filament

temperature

|

800-950°C

|

|

Material

|

Quartz

tube

|

|

Coating

|

Gold

|

|

Customization

|

Available

for

voltage,

wattage,

length,

base,

cables

and

burning

position

|

Product

Details

High-Quality

Coating

Options

The

semi-plated

white

coating

uses

special

quartz

powder

technology

to

reflect

over

90%

of

infrared

heat

in

the

same

direction,

significantly

reducing

energy

loss.

Standard

Product

Specifications

|

Voltage

(V)

|

Power

(W)

|

Size

(mm)

|

Total

Length

(mm)

|

Heating

Length

(mm)

|

Type

|

Model

1

|

Model

2

|

Model

3

|

|

220

|

1700

|

15x33

|

1280

|

1200

|

B

|

TMG100006

|

TMW100001

|

TMC100001

|

|

230

|

500

|

8x18

|

400

|

300

|

B

|

TMG100007

|

TMW100002

|

TMC100002

|

Contact

us

for

custom

specifications

-

our

professional

team

can

provide

technical

drawings

and

recommendations.

Industrial

Applications

-

Automotive:

Paint

drying,

plastic

welding,

adhesive

curing

-

Food

processing:

Fruit/vegetable

dehydration,

chocolate

melting

-

Glass

manufacturing:

Screen

printing,

bending,

laminating

-

Plastics

industry:

PVP

heating,

thermoplastic

processing

-

Semiconductors:

PCB

soldering,

capacitor

plate

drying

-

Textiles:

Fiber

drying

processes

-

Wood

processing:

Drying,

paint/ink

curing

After-Sales

Support

-

Package

tracking

for

all

shipments

-

Comprehensive

technical

support

-

24-hour

response

service

-

Discounts

for

repeat

orders

-

Quality

issue

replacements

-

Strict

customer

confidentiality

Frequently

Asked

Questions

Q1.

Can

I

request

samples

before

ordering?

A:

Yes,

we

welcome

sample

orders

to

evaluate

quality.

Mixed

samples

are

acceptable.

Q2.

What

is

the

typical

production

lead

time?

A:

Samples

require

5-7

days,

mass

production

typically

takes

30

days.

Q3.

Is

there

a

minimum

order

quantity?

A:

Standard

MOQ

is

2

pieces

per

model.

Q4.

What

shipping

methods

are

available?

A:

Samples

ship

via

DHL/UPS/FedEx/TNT.

Bulk

orders

use

air

or

sea

freight.

Q5.

How

does

the

ordering

process

work?

A:

1)

Share

your

requirements

2)

Receive

quotation

3)

Approve

samples

4)

Place

deposit

5)

Production

begins.

Q6.

What

is

your

quality

guarantee?

A:

All

products

undergo

strict

quality

control.

During

warranty

period,

replacements

ship

with

next

order.