IRP008

Gold

Plated

Preheating

Infrared

Baking

Lamp

Heidelberg

Heating

Accessories

Product

Specifications

|

Attribute

|

Value

|

|

Tube

diameter

|

15*33mm

|

|

Reflector

|

Gold

|

|

Total

length

|

900mm

|

|

Voltage

|

400V

|

|

Heating

length

|

560mm

|

|

Power

|

6950W

|

|

Material

|

Quartz

Tube

|

|

Place

of

Origin

|

Guangdong,

China

|

|

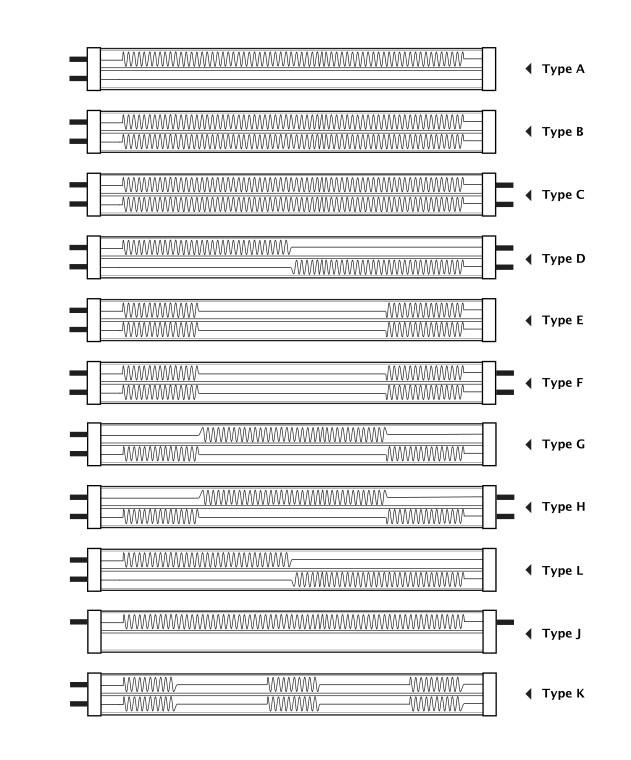

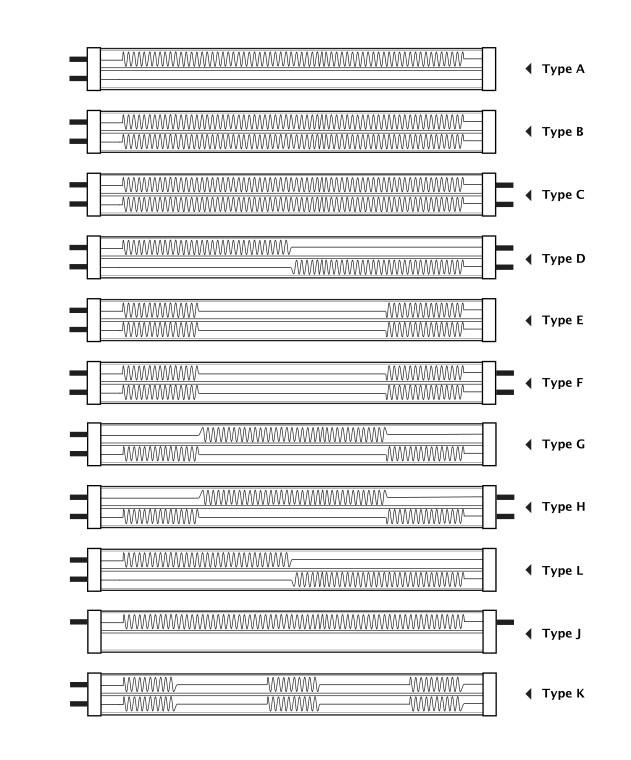

Construction

|

H

|

Product

Overview

IRP008

medium

wave

gold-plated

infrared

preheating

baking

lamp

designed

for

Heidelberg

printing

machines.

Our

company

specializes

in

manufacturing

ultraviolet

lamps,

infrared

lamps,

germicidal

lamps,

xenon

lamps,

and

related

accessories,

with

custom

solutions

available.

Key

Features

-

High

efficiency

heat

transmission

-

Cost-effective

operation

-

Rapid

on/off

response

time

-

Precise

heat

focusing

capability

Technical

Parameters

|

Type

|

IRP008

infrared

lamp

for

Printing

Machine

|

|

Size

|

11*23mm

|

|

Coating

|

Gold

|

|

Power

|

400V

|

|

Voltage

|

6950W

|

|

Customization

|

Available

for

voltage,

wattage,

length,

base,

cables,

and

universal

burning

position

|

Main

Components

-

Fused

silica

construction

-

Tungsten

heating

elements

-

Heating

wire

supports

-

End

plate

with

ceramic

components

-

Wire

leads

-

Gold

reflective

layer

-

Proprietary

gas

composition

Compatible

Models

|

Dryer

|

UVIR

Code

|

Lamp

Code

|

Energy

|

Volts

|

Watts

|

Total

Length

|

Tube

Cross

Section

|

Construction

|

Dryer

Detail

|

|

SM52

|

IRP001

|

SM52-SW-A

|

short

wave

|

415

|

3300

|

712

|

11*23

|

B

|

Grafix

Heidelberg

SM52

|

Applications

-

Infrared

heating

for

plastics

processing

-

IR

drying

of

coatings

on

plastics

-

IR

stretching

or

shrinking

plastics

-

Plastic

packaging

heating

-

Blow

moulding

of

PET

bottles

-

Printing

industry

applications

-

Ink

curing

on

cloth

-

Drying

for

inkjet-based

CTP

plates

-

Print

product

drying

(e.g.,

banners)

Infrared

Heating

Benefits

-

Precise

heating

without

surface

corrosion

-

Quick,

controllable

heating

cycles

-

Clean,

odorless

operation

-

No

environmental

contamination

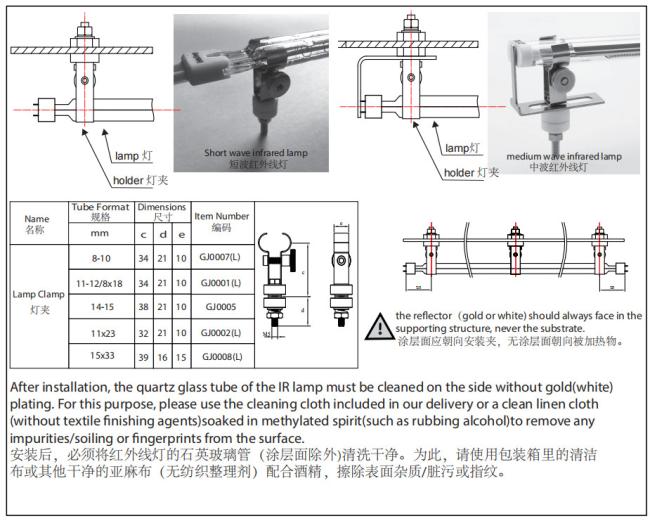

Installation

Guidelines

Always

turn

off

all

electrical

power

when

installing

or

replacing

lamps.

Important:

Infrared

emitters

should

never

be

operated

above

the

maximum

rated

voltage

(V

>

110%

of

rated

voltage)

to

prevent

damage.

Transportation