| Price | Negotiable |

| MOQ | 5 Pieces |

| Delivery Time | 1-4 weeks |

| Brand | BonTek |

| Place of Origin | China |

| Certification | ISO:9001 |

| Model Number | Sapphire (Al2O3) |

| Packaging Details | Cassette, Jar, Film package |

| Payment Terms | T/T |

| Supply Ability | 10000 pieces/Month |

| Place of Origin | China | Packaging Details | Cassette, Jar, Film package |

| Material | Sapphire Wafer | Model Number | Sapphire (Al2O3) |

| Thermal Conductivity | 27.21 W/(m x K) at 300 K | Hardness | Knoop 2000 kg/mm 2 with 2000g indenter |

| Supply Ability | 10000 pieces/Month | Density | 3.97 g/cm3 |

| Certification | ISO:9001 | Thermal Expansion | 5.6 x 10 -6 /K (parallel C-axis) & 5.0 (perpendicular C-axis) x 10 -6 /K |

| Brand Name | BonTek | Payment Terms | T/T |

| Specific Heat Capacity | 419 J/(kg x K) | Price | Negotiable |

| Delivery Time | 1-4 weeks | Minimum Order Quantity | 5 Pieces |

| Dielectric Constant | 11.5 (parallel C-axis) 9.4 (perpendicular C-axis) at 1MHz | Melting Point | 2040 degrees C |

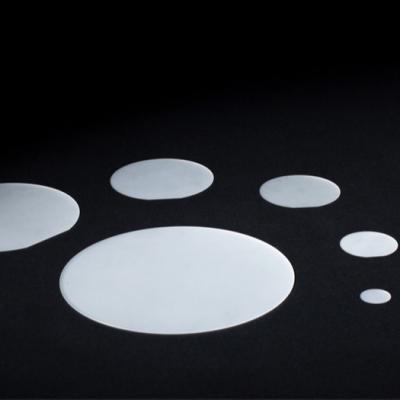

High Durability Sapphire Crystal Optics For Short And Long Wavelength Applications

Sapphire is used for short and long wavelength applications (UV and IR) beyond the range where conventional optics performs adequately. High temperatures and hostile environments also necessitate the use of sapphire optics.

·

Illumination

windows

-

for

very

high

brightness

illumination,

sapphire

windows

survive

the

very

high

heat

while

providing

the

broadest

spectral

transmission.

·

Sapphire

lightguides

-

sapphire

rods;

used

in

high

temperature

thermometry

beyond

the

range

of

quartz

optics.

·

Optical

components:

lenses,

prisms

and

other

laser

and

infrared

optics

are

fabricated

from

high

optical

quality

sapphire.

| OPTICAL PROPERTIES of SAPPHIRE Al2O3 | |

|

Transmission Range |

0.17 to 5.5 microns |

|

Refractive Index |

1.75449 (o) 1.74663 (e) at 1.06 microns |

|

Reflection Loss |

at 1.06 microns (2 surfaces) for o-ray - 11.7%; for e-ray - 14.2% |

|

Index of Absorption |

0.3 x 10-3 cm-1 at 2.4 microns |

|

dN/dT |

13.7 x 10-6 at 5.4 microns |

|

dn/dm = 0 |

1.5 microns |

| PHYSICAL PROPERTIES of SAPPHIRE Al2O3 | |

|

Density |

3.97 g/cm3 |

|

Melting Point |

2040 degrees C |

|

Thermal Conductivity |

27.21 W/(m x K) at 300 K |

|

Thermal Expansion |

5.6 x 10 -6 /K (parallel C-axis) & 5.0 (perpendicular C-axis) x 10 -6 /K |

|

Hardness |

Knoop 2000 kg/mm 2 with 2000g indenter |

|

Specific Heat Capacity |

419 J/(kg x K) |

|

Dielectric Constant |

11.5 (parallel C-axis) 9.4 (perpendicular C-axis) at 1MHz |

|

Young's Modulus (E) |

335 GPa |

|

Shear Modulus (G) |

148.1 GPa |

|

Bulk Modulus (K) |

240 GPa |

|

Elastic Coefficients |

C11=496

C12=164

C13=115 |

|

Apparent Elastic Limit |

275 MPa (40,000 psi) |

|

Poisson Ratio |

0.25 |

|

Orientation |

R-plane, C-plane, A-plane, M-plane or a specified orientation |

|

Orientation Tolerance |

± 0.3° |

|

Diameter |

2 inches, 3 inches, 4 inches, 6 inches, 8 inches or others |

|

Diameter Tolerance |

0.1mm for 2 inches, 0.2mm for 3 inches, 0.3mm for 4 inches, 0.5mm for 6 inches |

|

Thickness |

0.25mm, 0.33mm, 0.43mm, 0.65mm, 1mm or others; |

|

Thickness Tolerance |

25μm |

|

Primary Flat Length |

16.0±1.0mm for 2 inches, 22.0±1.0mm for 3 inches, 30.0±1.5mm for 4 inches, 47.5/50.0±2.0mm for 6 inches |

|

Primary Flat Orientation |

A-plane (1 1-2 0 ) ± 0.2°; C-plane (0 0-0 1 ) ± 0.2°, Projected C-Axis 45 +/- 2° |

|

TTV |

≤10µm for 2 inches, ≤15µm for 3 inches, ≤20µm for 4 inches, ≤25µm for 6 inches |

|

BOW |

≤10µm for 2 inches, ≤15µm for 3 inches, ≤20µm for 4 inches, ≤25µm for 6 inches |

|

Front Surface |

Epi-Polished (Ra< 0.3nm for C-plane, 0.5nm for other orientations) |

|

Back Surface |

Fine ground (Ra=0.6μm~1.4μm) or Epi-polished |

|

Packaging |

Packaged in a class 100 clean room environment |

Acceptance Check

1. The product is fragile. We have adequately packed it and labeled it fragile. We deliver through excellent domestic and international express companies to ensure transportation quality.

2. After receiving the goods, please handle with care and check whether the outer carton is in good condition. Carefully open the outer carton and check whether the packing boxes are in alignment. Take a picture before you take them out.

3. Please open the vacuum package in a clean room when the products are to be applied.

4. If the products are found damaged during courier, please take a picture or record a video immediately. DO NOT take the damaged products out of the packaging box! Contact us immediately and we will solve the problem well.