| Price | $3-$300 |

| MOQ | 1 Piece |

| Delivery Time | 10-15 days |

| Brand | MTH |

| Place of Origin | CHINA |

| Certification | ISO9001 |

| Model Number | 203mm diameter |

| Packaging Details | wooden case |

| Payment Terms | T/T, Western Union, MoneyGram |

| Supply Ability | 10000 pieces per month |

| Place of Origin | CHINA | Machine Type | Matching 8 '' hammer |

| Size | 3 '' - 17 7 / 10 '' | Use | Well Drilling,Ore Mining,quarry |

| Packaging Details | wooden case | Color | By customized |

| Material | Carbide,High Manganese Steel,Tungsten Carbide & Steel | Model Number | 203mm diameter |

| Supply Ability | 10000 pieces per month | Certification | ISO9001 |

| Brand Name | MTH | Payment Terms | T/T, Western Union, MoneyGram |

| Processing type | Forging | Packing | Wooden Case |

| Price | $3-$300 | Delivery Time | 10-15 days |

| Product name | DTH hammer bit | Minimum Order Quantity | 1 Piece |

| Application | Rock Drilling,Mining,Construction,quarry,Water Well drilling | Diameter | 8 '' , 203mm |

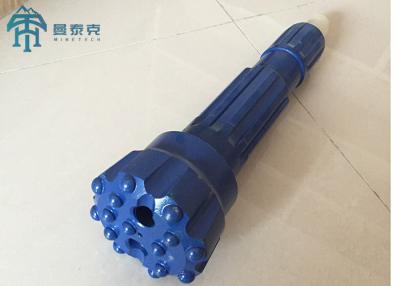

8 Inch Diameter 203mm DTH Hammer Bit Customized Color Mining Rock Drilling Tools

Product Information:

• Matching for DTH hammer.

• DTH hammer is a part of down hole drilling rig, which is a working device of down hole drilling rig. Submersible hole impactor is divided into low air pressure submersible hole impactor, medium air pressure submersible hole impactor and high air pressure submersible hole impactor.

Specification:

|

Bit size |

Shank type |

Recommended DTH bit diameter |

|

3.5''/3'' DTH Hammer bits |

COP34, DHD3.5, MISSION30, BR3 shank |

90mm to 105mm |

|

4'' DTH Hammer bits |

DHD340, QL40, MISSION40, SD4 shank |

110mm to 130mm |

|

5'' DTH Hammer bits |

DHD350, QL50, MISSION50, SD5 shank |

134mm tio 152mm |

|

6'' DTH Hammer bits |

DHD360, QL60, MISSION60, SD6 shank |

152mm to 203mm |

|

8'' DTH Hammer bits |

DHD380, QL80, MISSION80, SD8 shank |

203mm to 305mm |

|

12'' DTH Hammer bits |

DHD112, SD12 and QL120 shank |

Available upon to customers' request |

Applications:

•

Underground

mining

•

Quarry

benching

operations

•

Water

well

drilling

Charateristics:

The drill bit is the main component of the drilling rig and is the tool that transmits the impact energy and makes direct contact with the rock to blast.

The drill bit is subject to complex forces throughout its operation, so there are high requirements for the material and shape of the manufactured bit. When operating with the eccentric drill bit, it is necessary to grasp the technical essentials. The drilling parameters selected should be based on the principles of low speed, low feed pressure and high upward wind speed, and the drilling speed should be controlled during the construction operation according to the hardness, looseness and water content of the rocks in the stratum drilled. When the drill encounters a particularly loose or large fissure stratum, it is especially necessary to reduce the feed speed and feed pressure and repeatedly discharge slag to clear the hole.

Advantages:

•

High

drilling

efficiency,

long

drilling

tool

life,

submersible

impactor

drilling,

the

medium

is

air,

no

flushing

media

recovery

and

disposal

problems,

reducing

the

auxiliary

time.

•

Low

cost

of

use,

the

submersible

impactor

requires

small

shaft

pressure

and

low

speed

of

the

drilling

rig,

while

the

torque

is

low,

so

the

natural

power

consumption

is

small,

and

the

diameter

of

the

drill

pipe

is

relatively

thin,

easy

to

install

and

disassemble,

and

the

service

life

is

long.

• Submersible percussion drilling, the hole wall is more complete, there is no pollution from other media, basically can preserve The original formation structure and water permeability can be maintained, which reduces the well washing time and saves costs.

• In severe leakage formations and unstable hole wall formations, the submerged percussion can be used to follow the pipe drilling to completely solve the problem of repeated operations.

• As the submerged hole impactor uses wind as the power source, it greatly reduces the workload of cold-proofing in the previous winter construction due to the severe cold winter construction.