| Price | EXW/FOB/CIF/DDP |

| MOQ | Negotiable |

| Delivery Time | 15-25days |

| Brand | FODOR |

| Place of Origin | China |

| Certification | ISO9001:2015 |

| Model Number | S0014 |

| Packaging Details | common packaging |

| Payment Terms | T/T, Western Union |

| Supply Ability | 30000 PCS Per month |

| Place of Origin | China | Delivery time | 20-30days |

| Packaging Details | common packaging | Model Number | S0014 |

| Supply Ability | 30000 PCS Per month | Processing Service | Stamping |

| Certification | ISO9001:2015 | Brand Name | FODOR |

| Payment Terms | T/T, Western Union | Raw Material | Steel |

| Price | EXW/FOB/CIF/DDP | Delivery Time | 15-25days |

| Minimum Order Quantity | Negotiable | Surface Treatment | passivation |

| Application | switch |

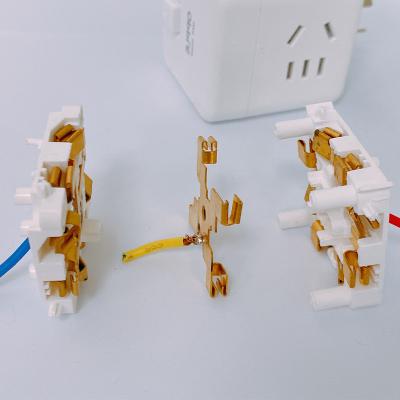

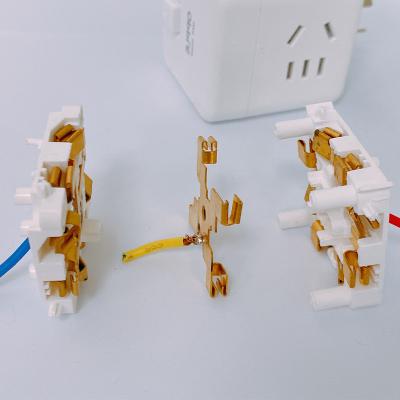

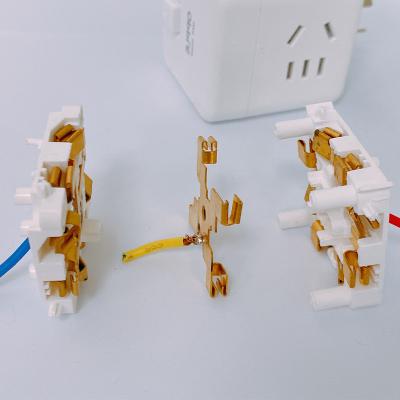

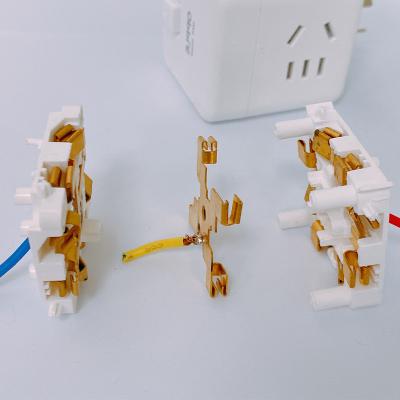

OEM Copper And Brass Terminal Blocks/ Connector Post/ Thimbles For Circuit Breakers And MCB Parts

Quick Detail

| Raw Material | copper |

| Custom Service | Yes, OEM/ODM Service |

| Quality System | ISO9001:2015 |

| Processing Technology | stamping/passivation |

| Surface treatment | Clear painting |

| Packing Way | Blister packaging or special packing you would like |

| Application Scenario | Electronic equipment heat sink |

| MOQ Request | 100/500/1000 |

Description

PRODUCT

MATERIAL

Steel,

Stainless

Steel,

Brass,

Copper,

bronze,

Aluminum,

Titanium,

silicon

steel,

nickel

plate

etc.

GENERAL

DESCRIPTION

There

are

mainly

three

kinds

of

Electrical

Contact

Component

:

1,Riveting

Parts

:

contact

is

riveted

on

copper

component

.

2,Welding

Parts

:

sheet

contact

is

welded

on

copper

component

.

3,Stamping

Parts:

precious

clad

metal

is

stamped

into

contact

bridge

component

The

manufacturing

and

test

equipment

for

making

Contact

Component

apparatus

such

as

digital

and

automotive

welding

stamping

machine,

riveting

machine,

welding

Automaton,

hi-speed

stamper,

stamper,

coloured

metallography

,microscope

,

3D

coordinator

etc.

We

can

develop

and

manufacture

contact

component

according

to

customers'

specific

requirement

and

the

output

can

surpass

one

billion

pieces

annually.

Copper alloys usually come in the form of brass, phosphor bronze, aluminum bronze, silicon bronze, cupronickel, and nickel silvers. Each of these alloys enhances the properties of copper and can be stamped for use in numerous applications across a broad spectrum of industries

Equipment

Used

to

Manufacture

Part45

Ton

Punch

Press

Cold

Heading

ToggleTest

EquipmentHardness

tester,Chemical

analysis,Digital

Measuring

Projector,

Dynamic

Balancing

Tester,

Plating

Tester

Tightest

TolerancesFlatness

of

±0.05Material

UsedTerminal:

Brass-CDA260,Copper

,Phosphor

copper

,Beryllium

Copper

OEM copper and brass Terminal blocks/ connector post/ Thimbles for circuit breakers and MCB part

Product overview:

Material

Carbon steel (hot rolled,cold rolled,strip steel), stainless steel, aluminum, brass ,s/s, brass, copper, bronze,

aluminum, plastic etc

Surface Treatment

Powder coating, hot galvanized, painting, polishing, brushing ,chrome/zinc/nickel plating,surface passivation, etc

Process

Stamping, punching, bending, welding, threading, grinding ,milling, machining, lathe,assembling etc

Press

From 25 MT to 100 MT

Tolerence

+/-0.01mm

Equipment

CNC shearing machine;CNC Puching machines;CNC bending machines;

Spot welding machines;Stamping machines

Cold press;Turning machine;Milling machine;Grinding machine

Products Available

Contact Components are widely used in low voltage electrical appliances and households, such as Switch Relay Thermal Controller Circuit Breaker Contactor Controller Timer, Bolts, screws, nuts, rivets, stem nuts, spring, connector, socket, push-button, etc.These parts are used in Automotive, Electrical, , Machine assembly, Air industry

If you are interest the product, please send your inquiry to me.I will offer the professional service.