| Price | EXW/FOB/CIF/DDP |

| MOQ | Negotiable |

| Delivery Time | 20-30days |

| Brand | Customized |

| Place of Origin | China |

| Certification | ISO9001:2015 |

| Model Number | LIQUID HEAT SINK-L0008 |

| Packaging Details | Blister packaging |

| Payment Terms | T/T, Western Union |

| Supply Ability | 30000 PCS Per month |

| Place of Origin | China | Delivery time | 20-30days |

| Keyword | liquid heat sink | Packaging Details | Blister packaging |

| Model Number | LIQUID HEAT SINK-L0008 | Supply Ability | 30000 PCS Per month |

| Processing Service | Cutting, CNC, Anodizing | Certification | ISO9001:2015 |

| Brand Name | Customized | Payment Terms | T/T, Western Union |

| Raw Material | Aluminum and pipe | Price | EXW/FOB/CIF/DDP |

| Delivery Time | 20-30days | Minimum Order Quantity | Negotiable |

| Surface Treatment | plating nickel | Application | heat sink |

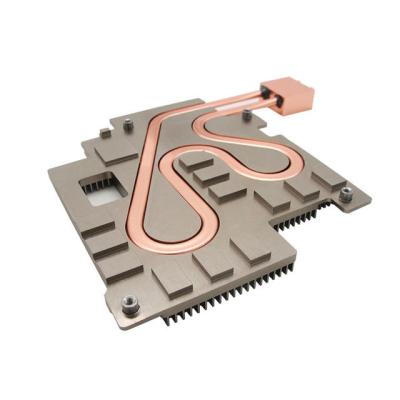

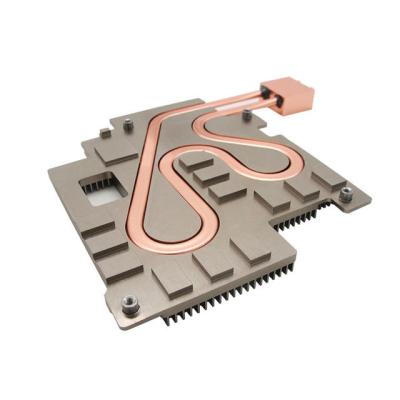

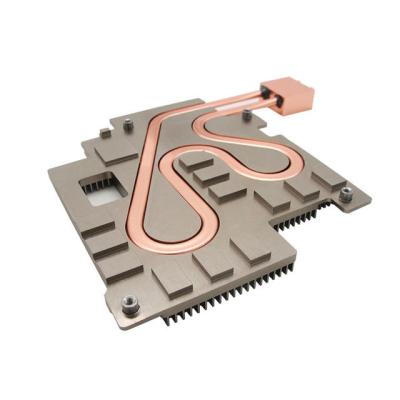

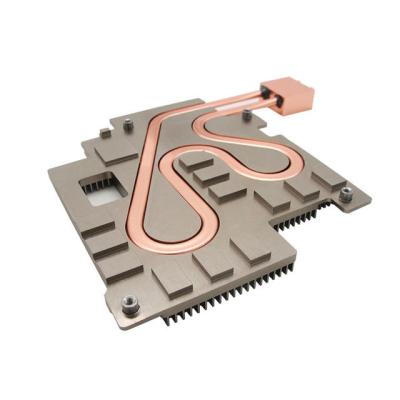

High Performance And Optimization Liquid Heat Sink For Power Electronics

Quick Detail

| Raw Material | AL1050 and pipe |

| Custom Service | Yes, OEM/ODM Service |

| Quality System | ISO9001:2015 |

| Processing Technology | Cutting/Wood machining/CNC/Riveting |

| Surface treatment | Plating nickel |

| Packing Way | Blister packaging or special packing you would like |

| Application Scenario | Electronic equipment heat sink |

| MOQ Request | 100/500/1000 |

Description

This heat sink is based aluminum profile 6063-T5 material to processing, first of all, we check the raw material dimension is fine or not, the second is that according to the drawing, cutting right length, the third is that accroding to the drawing, use the wood machine to cut the outline dimension, the forth is that use the CNC to do exact dimension, the fifth is do anodizing clear, the last step is riveting, and then inspection/packing. First inspection and patrol inspection are done in processing .

Note

Liquid heat sinks are also called water-cooled radiators and liquid-cooled radiators. They are generally made of aluminum and used to dissipate heat. They are mainly used in high-power devices, such as servers, inverters, inverters, APF, SVG, IGBTs, etc., remember to have A company called Fodor Radiator Factory specializes in aluminum radiators, water-cooling plates, etc. This will install the heating element on the water-cooling plate to dissipate heat, and the internal liquid is specially designated.

Customized Liquid Cooled Heatsinks

With tight collaboration with our customers, we can design and produce almost any kind of copper or aluminium liquid cooled heatsink (other materials on demand). Our designs take in consideration the internal situation of the power chips and an especific water circuit is designed for the optimal refrigeration of the power module. Do not hesitate to ask for your application needs.

Wide Range of Liquid Cooled Heatsinks

Copper and aluminium liquid cooled heatsinks with internal channel for semiconductor cooling through water, glycol and/or oil. Appropriate for high power converters in industrial facilities with cooling circuit systems and heat exchangers. We have a standard range and we can customise any design you require. The new RG82000 series implements new fabrication FSW technology for a very reliable and high performace coldplates. RG78000 series has been specially designed for IHM/IHV y PrimePACK™3 modules. RG77000 as a low cost solution with inserted cooling circuit. RG75000 series for press-pack devices and RG76000 for 62 mm completes the standard product range from our company.

We can offer the design and simulation service. For example, our German customer's case.

According to the simulation results,the simulated chip is in compliance with the temperature requirements specficied by customer.

Technical Support