| Price | EXW/FOB/CIF/DDP |

| MOQ | 100 |

| Delivery Time | 20-30days |

| Brand | Customized |

| Place of Origin | China |

| Certification | ISO9001:2015 |

| Model Number | HEAT SINK-H0002 |

| Packaging Details | Blister packaging |

| Payment Terms | T/T, Western Union, L/C |

| Supply Ability | 300000 PCS Per month |

| Usage | industial | Place of Origin | China |

| Delivery time | 15-30days | Keyword | aluminum profile heat sink |

| Packaging Details | Blister packaging | Model Number | HEAT SINK-H0002 |

| Supply Ability | 300000 PCS Per month | Processing Service | Cutting, CNC,Anode |

| Certification | ISO9001:2015 | Brand Name | Customized |

| Payment Terms | T/T, Western Union, L/C | Raw Material | AL6063-T5 |

| Price | EXW/FOB/CIF/DDP | Delivery Time | 20-30days |

| Minimum Order Quantity | 100 | Surface Treatment | Black Anodizing |

| Application | heat sink |

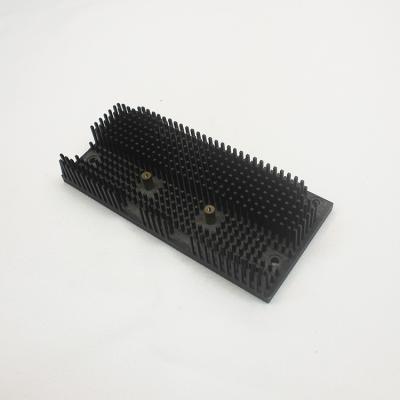

Black Anodizing CNC AL6063-T5 Aluminum Profile Heat Sink For Industrial Electronics Products

Quick Detail

| Raw Material | AL6063-T5 |

| Custom Service | Yes, OEM/ODM Service |

| Quality System | ISO9001:2015 |

| Processing Technology | Cutting/Wood machining/CNC/Riveting |

| Surface treatment | clean |

| Packing Way | Blister packaging or special packing you would like |

| Application Scenario | heat sink |

| MOQ Request | 100/500/1000 |

Description

This heat sink is based aluminum profile 6063-T5 material to processing, first of all, we check the raw material dimension is fine or not, the second is that according to the drawing, cutting right length, the third is that accroding to the drawing, use the wood machine to cut the outline dimension, the forth is that use the CNC to do exact dimension, the fifth is do anodizing clear, the last step is riveting, and then inspection/packing. First inspection and patrol inspection are done in processing .

Notes

This is clean aluminum profile heat sink.

The materials for heat sink applications should have high heat capacity and thermal conductivity in order to absorb more heat energy without shifting towards a very high temperature and transmit it to the environment for efficient cooling.[7] The most common heat sink materials are aluminum alloys.[8] Aluminum alloy 1050 has one of the higher thermal conductivity values at 229 W/(m·K) and heat capacity of 922 J/(kg-K),[9] but is mechanically soft. Aluminum alloys 6060 (low-stress), 6061, and 6063 are commonly used, with thermal conductivity values of 166 and 201 W/(m·K) respectively. The values depend on the temper of the alloy. One-piece aluminum heat sinks can be made by extrusion, casting, skiving or milling.

We offer some styles surface treatment: Anodizing/ hard anodizing, chromate, nickel plating and so on, please send your inquiry to Fodor , we will offer the professional service for you.