| Price | EXW/FOB/CIF/DDP |

| MOQ | 100 |

| Delivery Time | 20-30days |

| Brand | Customized |

| Place of Origin | China |

| Certification | ISO9001:2015 |

| Model Number | HEAT SINK-H00011 |

| Packaging Details | Blister packaging |

| Payment Terms | T/T, Western Union, L/C |

| Supply Ability | 300000 PCS Per month |

| Place of Origin | China | Delivery time | 15-30days |

| Keyword | heat sink | Packaging Details | Blister packaging |

| Model Number | HEAT SINK-H00011 | Supply Ability | 300000 PCS Per month |

| Processing Service | Cutting, CNC, Anodizing | Certification | ISO9001:2015 |

| Brand Name | Customized | Payment Terms | T/T, Western Union, L/C |

| Raw Material | AL6063-T5/6061 | Price | EXW/FOB/CIF/DDP |

| Delivery Time | 20-30days | Minimum Order Quantity | 100 |

| Surface Treatment | Hard Anodizing | Application | electronics heat sink |

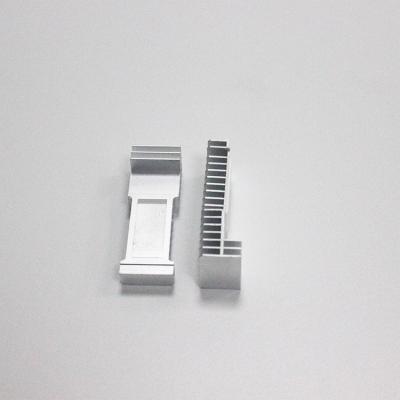

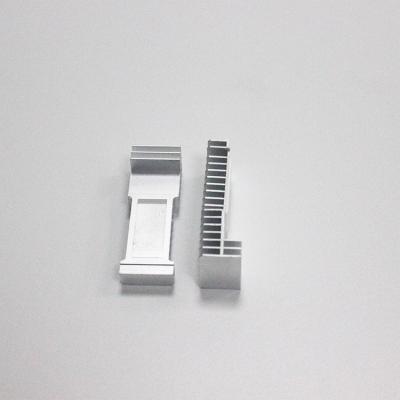

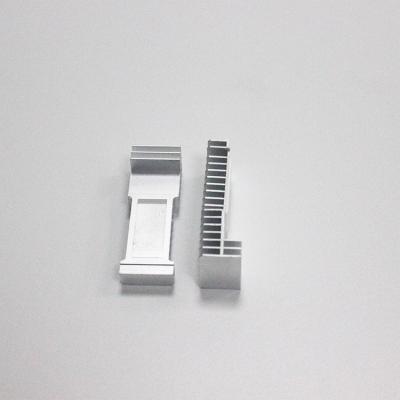

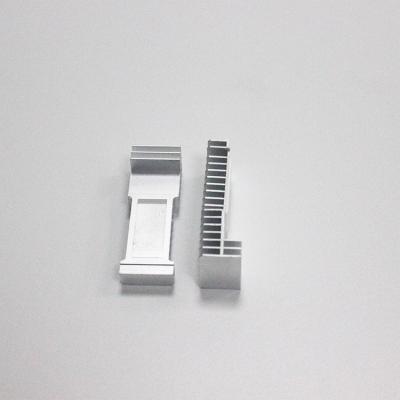

Hard Anodizing 25 Micron Aluminum Profile Heat Sink For Custom Request

Quick Detail

| Raw Material | AL6063-T5 |

| Custom Service | Yes, OEM/ODM Service |

| Quality System | ISO9001:2015 |

| Processing Technology | Cutting/Wood machining/CNC/Riveting |

| Surface treatment | Hard Anodizing |

| Packing Way | Blister packaging or special packing you would like |

| Application Scenario | Electronic equipment heat sink |

| MOQ Request | 100/500/1000 |

Description

This heat sink is based aluminum profile 6063-T5 material to processing, first of all, we check the raw material dimension is fine or not, the second is that according to the drawing, cutting right length, the third is that accroding to the drawing, use the wood machine to cut the outline dimension, the forth is that use the CNC to do exact dimension, the fifth is do anodizing clear, the last step is riveting, and then inspection/packing. First inspection and patrol inspection are done in processing .

Notes

This is Aluminum Profile heat sink

Why do they make heat sinks out of aluminum?

It is cost-effective, simple to make, and lightweight. This is why it is a great choice for different heat sinks. It can easily move at a rate close to copper. This reduces the distance of conducting and moving heat from the source.