| Price | Negotiable |

| MOQ | 1 SET |

| Delivery Time | 8-12 weeks |

| Brand | KEYE |

| Place of Origin | China |

| Certification | NO |

| Model Number | KVIS-B |

| Packaging Details | Fumigation-free wood |

| Payment Terms | L/C, T/T |

| Supply Ability | 1500 set per year |

| Condition | New | Place of Origin | China |

| Place of origin | China | Sample | FMCG |

| Packaging Details | Fumigation-free wood | Material | SS 304/Carbon Steel |

| Model Number | KVIS-B | Supply Ability | 1500 set per year |

| Certification | NO | Weight | 500kg |

| MOQ | 1 Set | Name | Visual Inspection System |

| Touch screen | 21 inches | Brand Name | KEYE |

| Payment Terms | L/C, T/T | Payment | T/T, L/C |

| Price | Negotiable | Delivery Time | 8-12 weeks |

| Minimum Order Quantity | 1 SET |

HD Industry Camera Visual Inspection System For Beverages Filling Line

System description

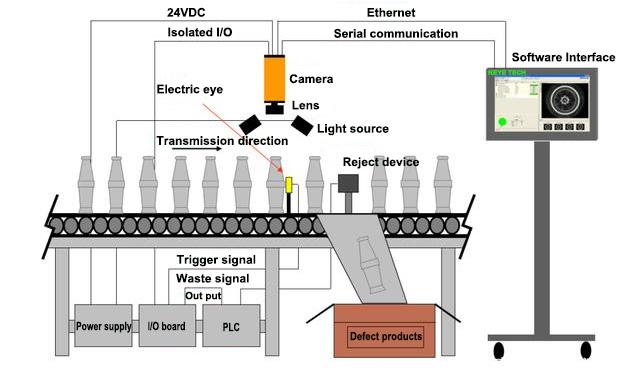

The system adopts imported high-resolution industrial cameras, which can quickly acquire images. Through image recognition, analysis and calculation, it can detect whether there are defective products in button production in real time, and output corresponding detection signal prompts to facilitate the processing of defective products.

| Model | Number Of Camera | Inspection Scope | Inspection Content | Detection Precision | Accuracy | Capacity |

| Kvis-Cc06 | 4 set | Outside Surface | Black Spot≥0.2mm | 99.8% | 99% | 500pcs/min |

| 0.5mm<Flash, Injection Incomplete≤1mm | 99% | |||||

| 1set | Concave Surface | 0.5m<Injection Incomplete≤1mm | 99.8% | |||

| Black Spot≥0.2mm | 99.8% | |||||

| 2mm<Transformation | 99% | |||||

| 1set | Trademark Surface | Black Spot≥0.2mm | 99.8% | |||

| Note: The System Equipped With 2 Million Pixel-Level Industrial Cameras. | ||||||

Function of Vision Machine

The machine vision system uses machines to replace the human eye to make various measurements and judgments. It is an important branch of computer science. It integrates technologies such as optics, machinery, electronics, computer software and hardware, and involves many fields such as computer, image processing, pattern recognition, artificial intelligence, signal processing, and opto-mechanical integration. . The rapid development of technologies such as image processing and pattern recognition has also greatly promoted the development of machine vision. It is invaluable in its ability to detect defects and prevent defective products from being shipped to consumers.

Features of equipment

Relying on the mature machine vision system, KEYE TECH has developed online visual inspection equipment for food and beverage production lines, covering: inkjet inspection machine, preform inspection machine, preform mouth inspection machine, capping liquid level inkjet code inspection machine, label inspection machine, aluminum Membrane sealing machine, cans inspection machine for cans, glass bottle empty bottle inspection machine, etc. At the same time, we can provide customized visual inspection system services according to customer needs.

Machine

vision

inspection

technology

is

mainly

to

improve

the

accuracy,

automation

level

and

flexibility

of

product

inspection

in

the

production

line,

which

can

effectively

help

enterprises

reduce

labor

costs

and

ensure

the

safety

of

employees

who

have

dangerous

operations.

1.

The

application

is

limited.

The

non-contact

measurement

will

not

cause

any

damage

to

the

observer

and

the

observed,

thereby

improving

the

reliability

of

the

system.

2.

Wide

application.

Has

a

wide

spectral

response

range,

such

as

using

infrared

measurements

that

are

invisible

to

the

human

eye,

extending

the

visual

range

of

the

human

eye.

3.

Long-term

stable

and

accurate

detection.

It

is

difficult

for

humans

to

observe

the

same

object

for

a

long

time,

while

machine

vision

can

perform

measurement,

analysis

and

recognition

tasks

for

a

long

time,

and

can

complete

production

tasks

with

quality

and

quantity.

4.

The

detection

speed

is

fast.

It

can

be

matched

with

suitable

visual

inspection

equipment

according

to

the

high-speed

production

capacity

of

the

production

line.