| Price | Negotiable |

| MOQ | 1 SET |

| Delivery Time | 4 to 6 weeks |

| Brand | KEYE |

| Place of Origin | China |

| Certification | NO |

| Model Number | KVIS-DR-O Ring |

| Packaging Details | Fumigation-free wood |

| Payment Terms | L/C, T/T |

| Supply Ability | 1 set per 4 weeks |

| Speed | 200-300/min | Place of Origin | China |

| Packaging Details | Fumigation-free wood | Color | Grey |

| Material | SS 303 | Model Number | KVIS-DR-O Ring |

| Supply Ability | 1 set per 4 weeks | Algorithm | Deep learning |

| Certification | NO | Name | Aoi Machine Vision For Rubber Sealing Ring |

| Brand Name | KEYE | Payment Terms | L/C, T/T |

| Price | Negotiable | Delivery Time | 4 to 6 weeks |

| Quality | High grade | Minimum Order Quantity | 1 SET |

| Voltage | Adapt to national standards | Package | Wood packing |

Product background

Inspection principle

The materials are arranged by vibrating plate, Linear vibration and non-destructive conveying, and the capacitance is stably and orderly transferred to the specific inspection station, and then the high-pixel sample image captured by the industrial camera is transferred to the image processing software. After the system analyzes and processes, it judges good and defective products, and controls the corresponding pneumatic components to eliminate the defective products, and finally collects qualified products.

The traditional manual inspection method has been difficult to meet the inspection needs of the production process of automobile oil seals. To ensure high-quality products, modern testing equipment is inseparable. The introduction of automated visual testing equipment is an essential choice in the production of automotive oil seals. Quality control is now the core competitiveness among manufacturers in the manufacturing supply chain.

Inspection details&machine configurations

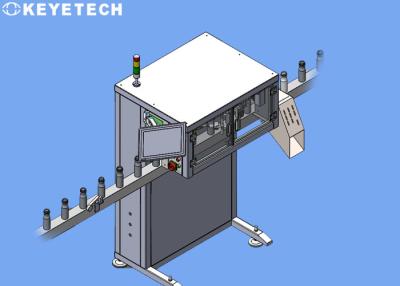

The inspection machine adopts high-pixel industrial cameras and high-performance stroboscopic light sources to carry out omni-directional visual inspections for product appearance defects. The equipment can realize 7*24 hours of all-weather operation, and it can be online automatically. Eliminate substandard products.

| Name | Rubber sealing ring Inspection machine | Size | 900*800*1850mm |

| Computer | Industrial PC | Monitor | 19 inch |

| Industrial camera | 2 set | Industrial lens | 2 set |

| Glass turntable | 1 pcs | Samples | 0.6-30mm(diameter) |

| Feeding equipment | vibration plate, direct vibration, controller | Speed | 200-400/min |

Our advantages

| 1.AI algorithm: high stability, adapting to the environment and background disturbance; different defect samples can be automatically identified after training |

| 2.Dataization: Independent database, save multiple samples, analyze non-good products, and retain history |

| 3.Multi-orientation: 360 ° comprehensive inside and outside the samples |

| 4.High precision: detection accuracy can be high |

| 5.Modularization, can flexibly increase or decrease the detection function according to customer actual needs |

| 6.Easy to operate: It is easy to operate and easy to maintain |

| 7.Safety: Medical grade material manufacturing, fully compliant with medical supplies production environment |