| Price | Negotiable |

| MOQ | 1 SET |

| Delivery Time | 8 to 10 weeks |

| Brand | KEYE |

| Place of Origin | China |

| Certification | CE/ISO 9001 |

| Model Number | KY-PC |

| Packaging Details | Fumigation-free wood |

| Payment Terms | L/C, T/T |

| Supply Ability | 1500 set per year |

| Light source | LED | Usage | Rigid Plastic Packaging |

| Place of Origin | China | Packaging Details | Fumigation-free wood |

| Selling points | Compressed air (non-pollution) | Model Number | KY-PC |

| Supply Ability | 1500 set per year | Key technology | AI inspection |

| Certification | CE/ISO 9001 | Touch screen | Liquid crystal |

| Brand Name | KEYE | Payment Terms | L/C, T/T |

| Function | Selection | Price | Negotiable |

| Delivery Time | 8 to 10 weeks | Minimum Order Quantity | 1 SET |

| False rate | 0.5% | Number of cameras | 6 sets |

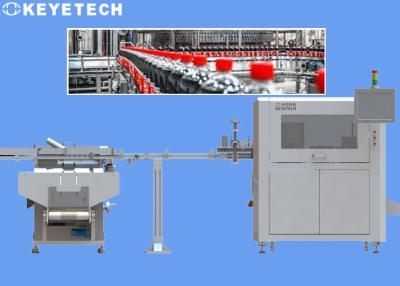

Sport Cap Visual Inspection System for Liquid Beverage Packaging

Inspection Principle

Judging from the existing pharmaceutical manufacturing enterprises, they are all developing at a relatively rapid rate. The speed of mergers and reorganizations in the pharmaceutical industry has accelerated. Such a speed of development will put forward higher requirements for the production capacity and product quality of pharmaceutical packaging companies. Changes in external market demand will promote the development of pharmaceutical packaging in the direction of large-scale development, which poses a great challenge for pharmaceutical packaging companies.

The design plan for our company is equipped with industrial cameras, a cap organize machine to realize a full range of defect detection on the concave, trademark and side of the bottle caps. The normal detection speed is 500 pieces per minute; The front part of the detection machine can be equipped with a set of organize conveying equipment to transport the bottle caps into the detection equipment in a regular and orderly manner. The detection equipment is divided into 3 major detection system modules: the first module is to realize the defect detection function in the concave and the side of the cap.

Detection software function:

| Model | Camera number | Detection range | Detection content and accuracy | Detection precision | Accuracy of detection | Detection speed | Remark |

| KVIS-CC06 |

4 sets |

Outside area |

Black spots≥0.2mm | 99.5% | 99% | 500 pcs/min | |

| 0.5mm<overlap and lack of material≤1mm | 99.5% | ||||||

|

1 set |

Concave area |

0.5m<lack of material≤1mm | 99.5% | ||||

| Black spots≥0.2mm | 99.5% | ||||||

| 2mm<Deformed | 99.5% | ||||||

|

1 set |

Trademark area |

Black spots≥0.2mm | 99.5% | ||||

| Note: This equipment adopts 2 million pixel level industrial cameras. | |||||||

Machining Process

Machine Maintenance

Others