| Price | Negotiable |

| MOQ | 1 SET |

| Delivery Time | 4 to 6 weeks |

| Brand | KEYE |

| Place of Origin | China |

| Certification | NO |

| Model Number | KVIS-B |

| Packaging Details | Fumigation-free wood |

| Payment Terms | L/C, T/T |

| Supply Ability | 1 set per 6 weeks |

| Place of Origin | China | Warranty | ONE YEAR |

| Packaging Details | Fumigation-free wood | Color | According To Customer's Need |

| SIZE | 2300*1200*1850mm | Model Number | KVIS-B |

| Supply Ability | 1 set per 6 weeks | Certification | NO |

| Weight | 400kg | Name | Plastic Pharmaceutical Bottle Inspection Machine |

| BOTTLE DIAMETER | 10mm~120mm | Brand Name | KEYE |

| Payment Terms | L/C, T/T | Function | Separate Bad Out From Good Sorting |

| Accuracy | 99.98% | Price | Negotiable |

| Delivery Time | 4 to 6 weeks | Minimum Order Quantity | 1 SET |

| Camera | Inside/Outside Light Camera | Loading port | Shanghai |

Plastic Pharmaceutical Bottle Inspection Machine High Precision Accuracy Sorting Device

Inspection standards

| Model | Number of camera | Inspection scope | Inspection content | Detection precision | Accuracy | Capacity |

|

KVIS-SC10

|

1 set | Bottle lip area | Black spot, stain, impurity | ≥0.2mm | 99% | 120/min |

| flash, injection incomplete | ≥1.0mm | 99% | ||||

| 4 sets | Upper area of bottle body | Black spot, stain, impurity | ≥0.2mm | 99% | ||

| Bubble | ≥1.0mm | 99% | ||||

| 4 sets | Lower area of bottle body | Black spot, stain, impurity | ≥0.2mm | 99% | ||

| Bubble | ≥1.0mm | 99% | ||||

| 1 set | Outside of bottle base | Black spot, stain, impurity | ≥0.2mm | 99% | ||

| Injection point offset | ≥1.5mm | 99% | ||||

| Hole | ≥1.0mm | 99% |

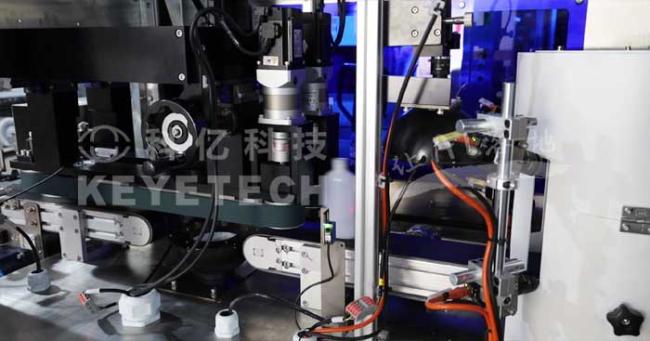

Inspection Principle

Many pharmaceutical and health care product manufacturers use automated methods for pre-production, post-packaging, and post-packaging testing to reduce inefficiency and huge labor and management costs caused by manual inspection. In order to meet the quality requirements, many pharmaceutical factories combine machine vision systems and automated machines (production line machines) to eliminate products with black spots, dirt, flashes, material shortages, deformation and other defects in medicine bottles through high-speed shooting of data. High quality and efficient production line process.

In the inspection process of medicine bottles, with the help of the machine vision system, the overall inspection efficiency and inspection accuracy are greatly improved compared with the previous manpower efficiency. The industrial camera in the inspection machine system can capture the image of each passing medicine bottle on the high-speed production line, and then analyze the good/defective product through the back-end image software analysis, and can also record the image data so that the subsequent sequence can be Quickly and accurately query, trace and retrieve items. Various automatic auxiliary machines can also be connected to the front and back ends of the inspection to comprehensively improve the automation level of the production line.

System features

Our advantages

The medicine bottle inspection machine system can greatly improve the quality of medicine bottle production, reduce defects and improve customer satisfaction satisfaction and get more production orders.