| Price | Negotiable |

| MOQ | 200PCS |

| Delivery Time | 20 work days |

| Brand | Beecore |

| Place of Origin | China |

| Certification | Can be provided |

| Packaging Details | plywood case |

| Payment Terms | L/C, T/T |

| Supply Ability | 300 SM per month |

| Service life | Over 20 years | Side length | 3, 4, 5, 6, 7, 8, 9, 10, 12, 15, 20 |

| Place of Origin | China | Sound reduction index, dB | 26 |

| Packaging Details | plywood case | Material | Aluminium/Stainless steel |

| Dimension | 1500*2440mm or can be customized | Wall thickness | 0.1、0.13、0.15、0.2 etc. |

| Supply Ability | 300 SM per month | Density | Less than 0.7g/cm3 |

| Certification | Can be provided | Brand Name | Beecore |

| Payment Terms | L/C, T/T | Thickness | 5mm,8mm,1mm,10mm,20mm,40mm or can be customized |

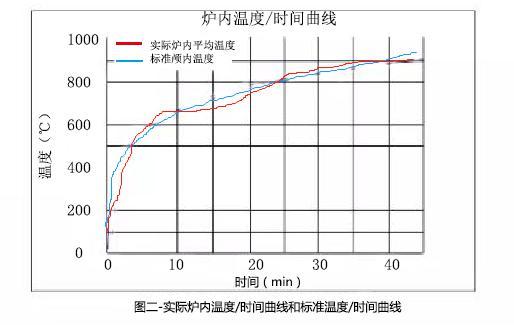

| Thermostability | 600℃ | Fire rating | A1 |

| Delivery Time | 20 work days | Minimum Order Quantity | 200PCS |

| Structure | Edge-sealed/unedge-sealed |

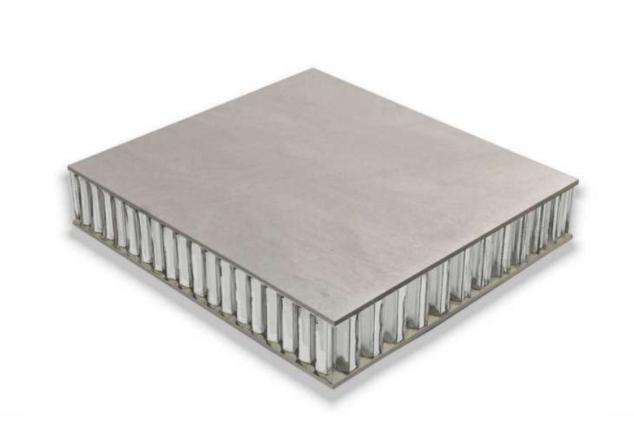

Description: 75mm Thickness Brazed Aluminum Honeycomb Panel For Oil Floating Disc

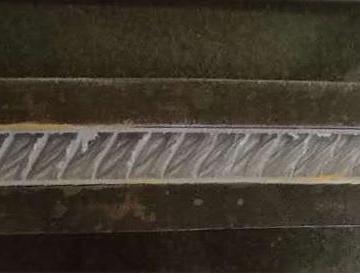

Brazed aluminum honeycomb panel is a metal structural material that uses aluminum honeycomb as the core material, with aluminum or stainless steel panels on both sides, and then combines them together for one-time brazing. The main materials used are solder, tin, and stainless steel.

It overcomes the drawback that the honeycomb core of the existing adhesive honeycomb panels is greatly affected by the performance of the adhesive. Its mechanical properties are much higher than those of the adhesive materials, and all properties have been significantly improved, making it suitable for industrial production.

Mechanical performance

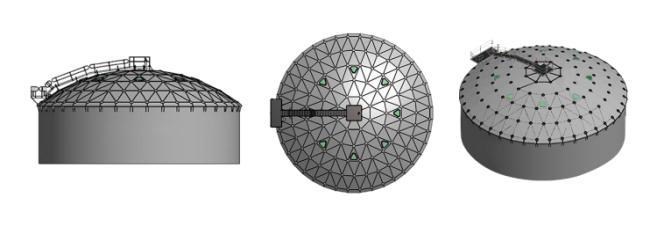

Petrochemical Industry